Water drop type crusher for livestock feed processing

A technology of feed processing and pulverizer, which is applied in the direction of feed, application, grain processing, etc., and can solve problems such as environmental pollution, injury, and inability to use scientifically and effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

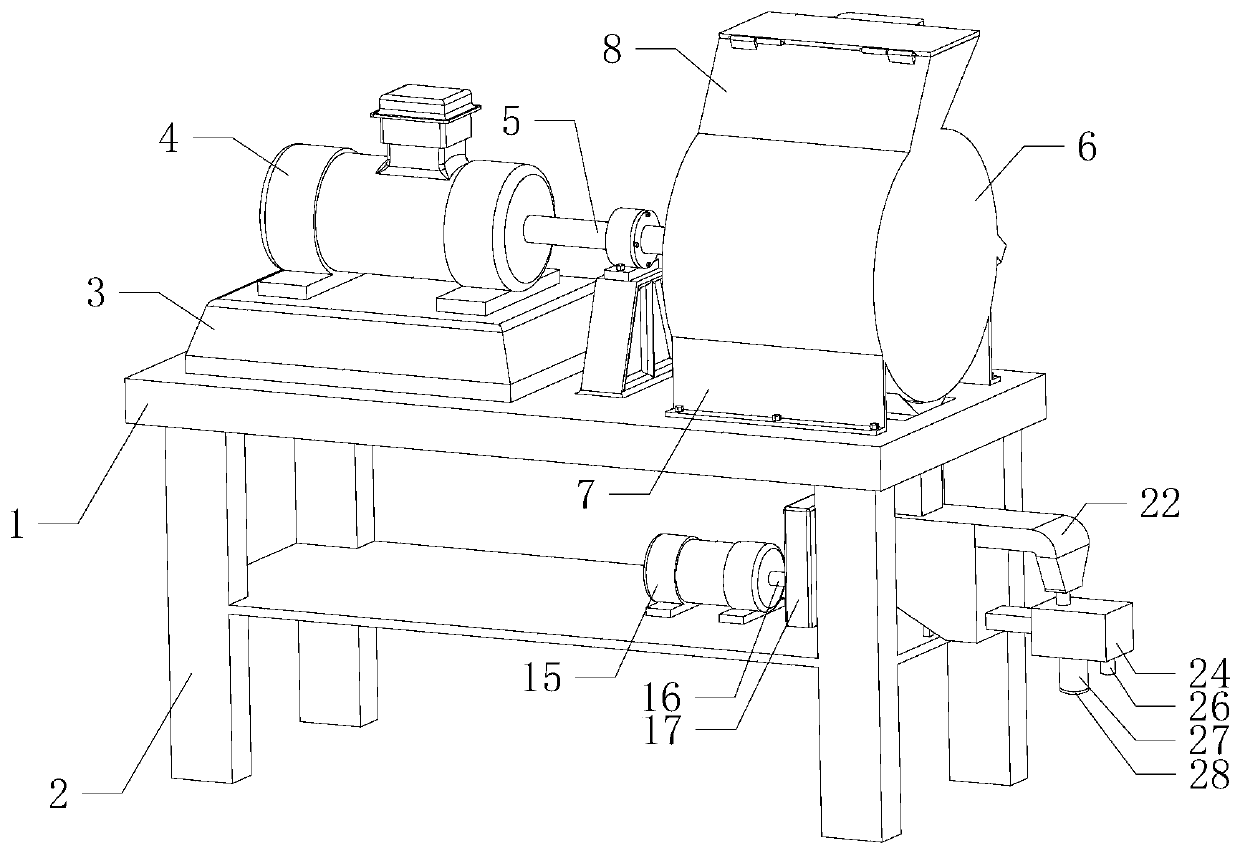

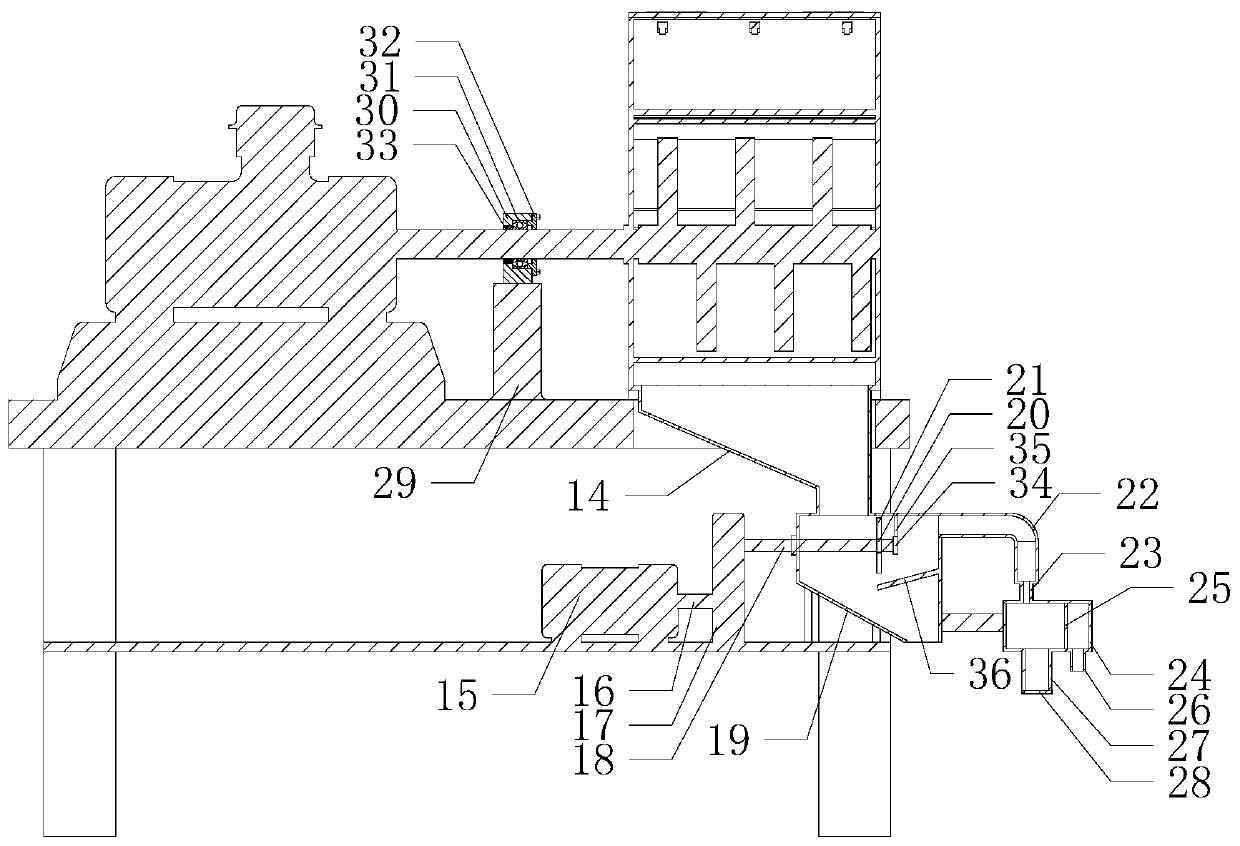

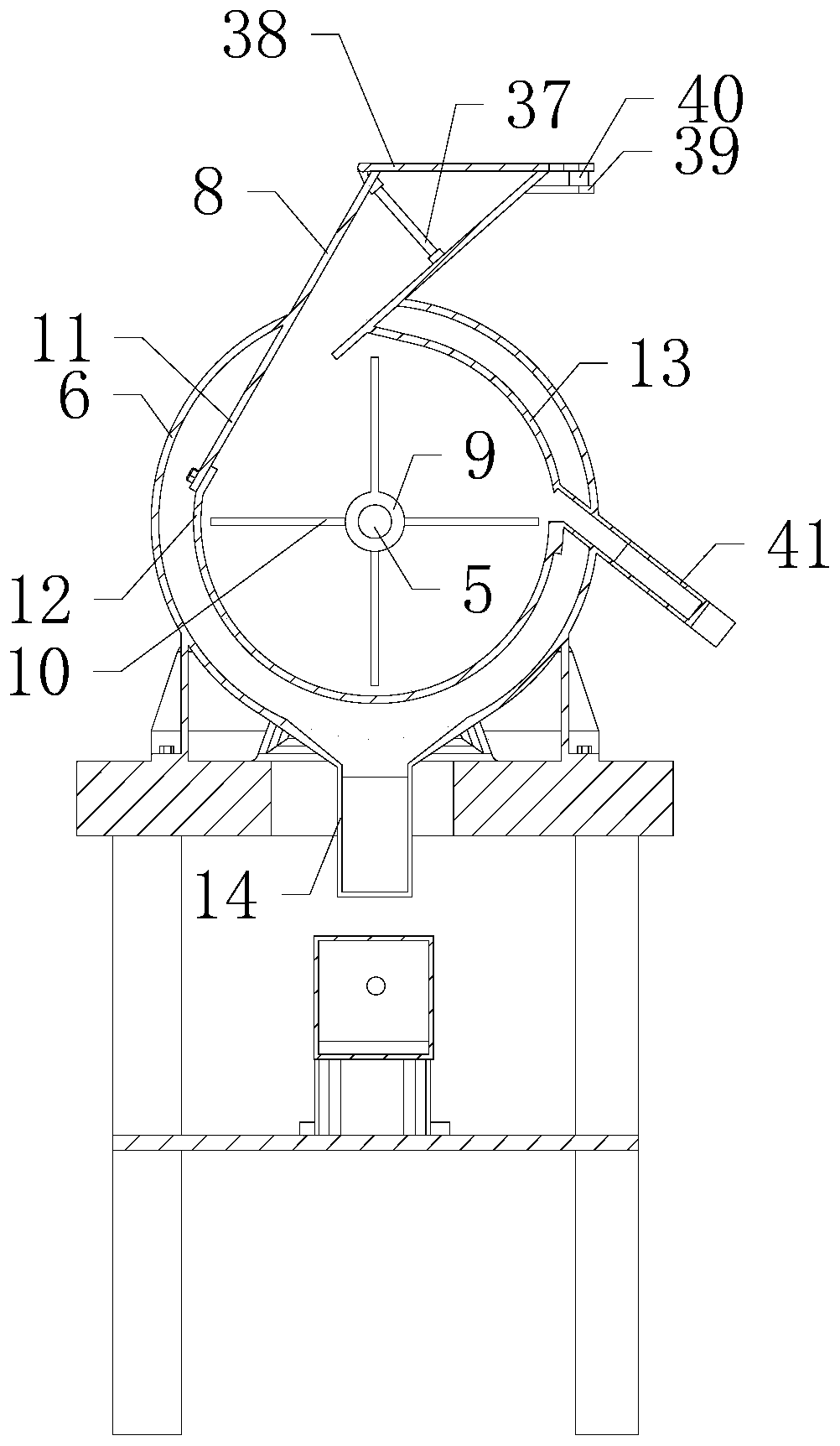

[0019] Such as Figure 1 to Figure 4 As shown, the water droplet grinder for poultry and livestock feed processing of the present invention, when in operation, first turn on the first motor 4, the first motor 4 drives the first rotating shaft 5 to rotate, and the first rotating shaft 5 passes through the first rotating sleeve 9 drives multiple groups of crushing rods 10 to rotate, and then opens the second cover plate 38 through the push plate, and pours the livestock feed into the upper side of the first cavity through the inlet hole on the hopper 8. The three groups of first magnetic blocks are 37 pairs The feed in the feed hole is screened to facilitate the adsorption and isolation of iron objects in the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com