Screening and drying device

A technology of drying device and conveying device, applied in heating device, cyclone device, filter screen, etc., can solve the problems of reducing screening efficiency, blocking crops in screening drum or screening net, increasing labor time, etc., so as to improve screening efficiency, reduce Effect of drying screening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

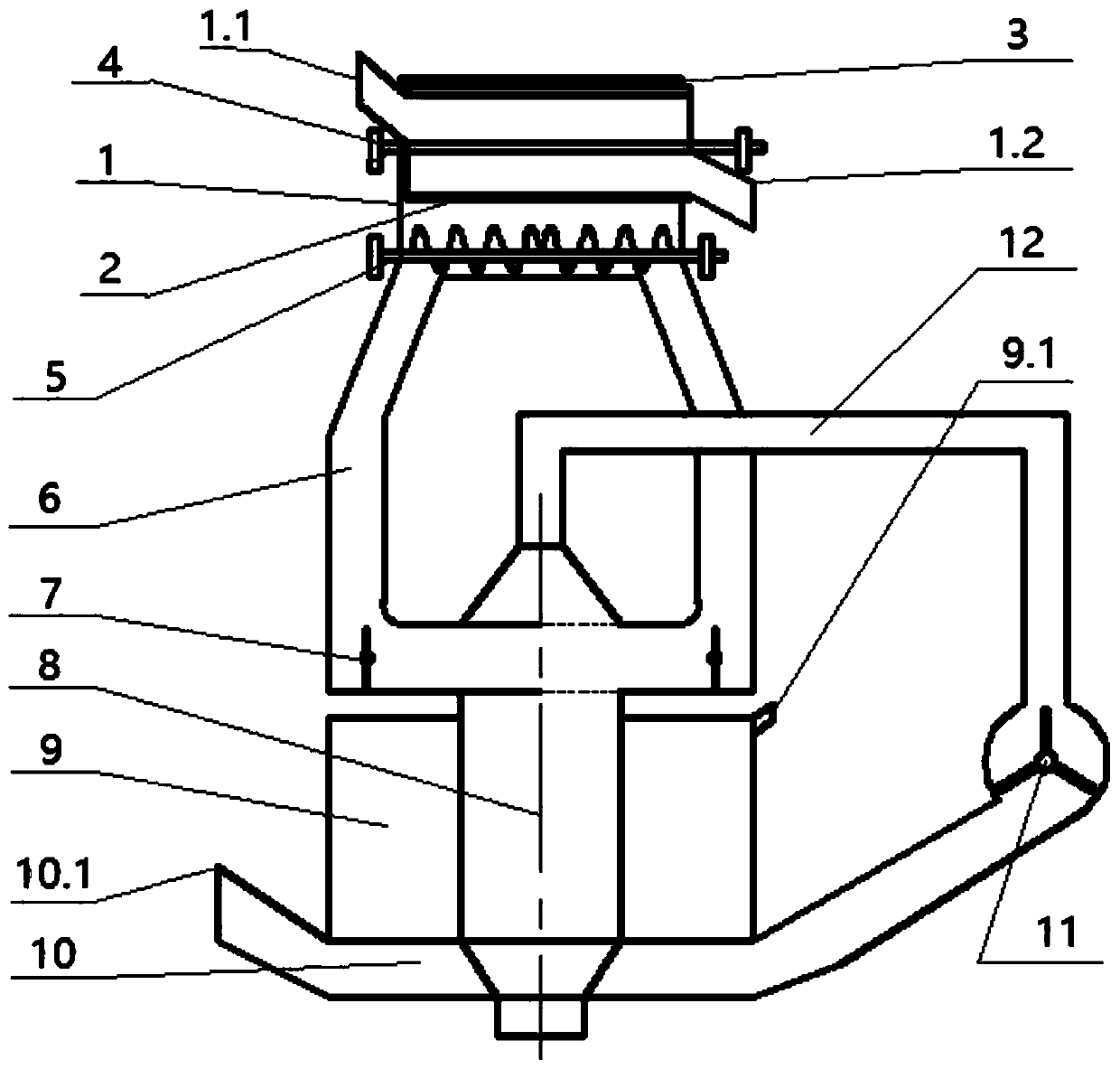

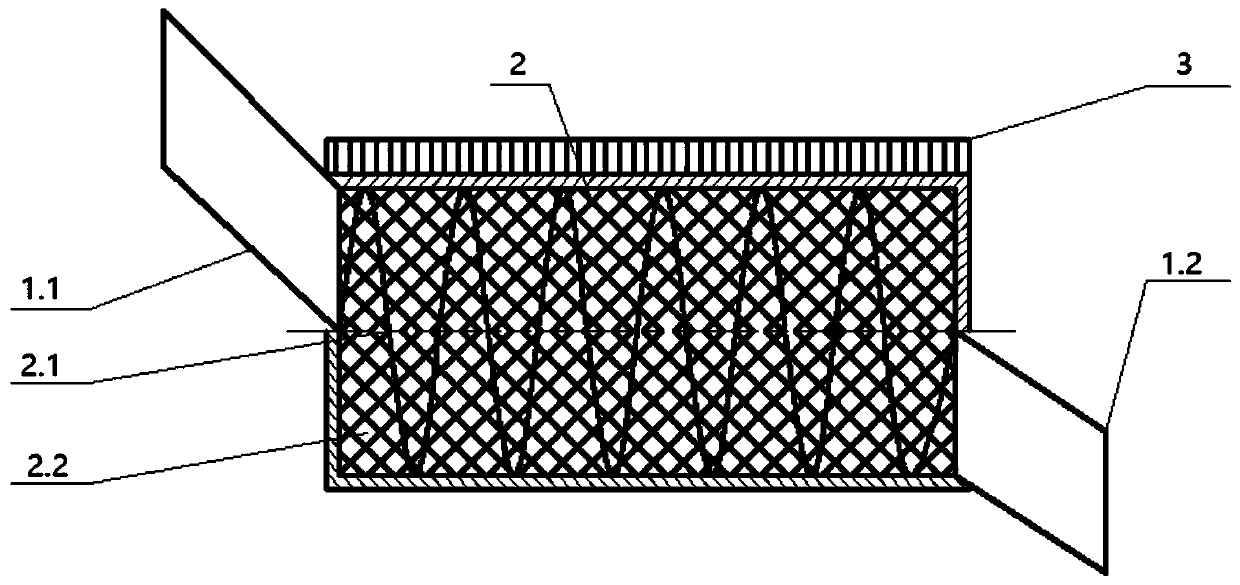

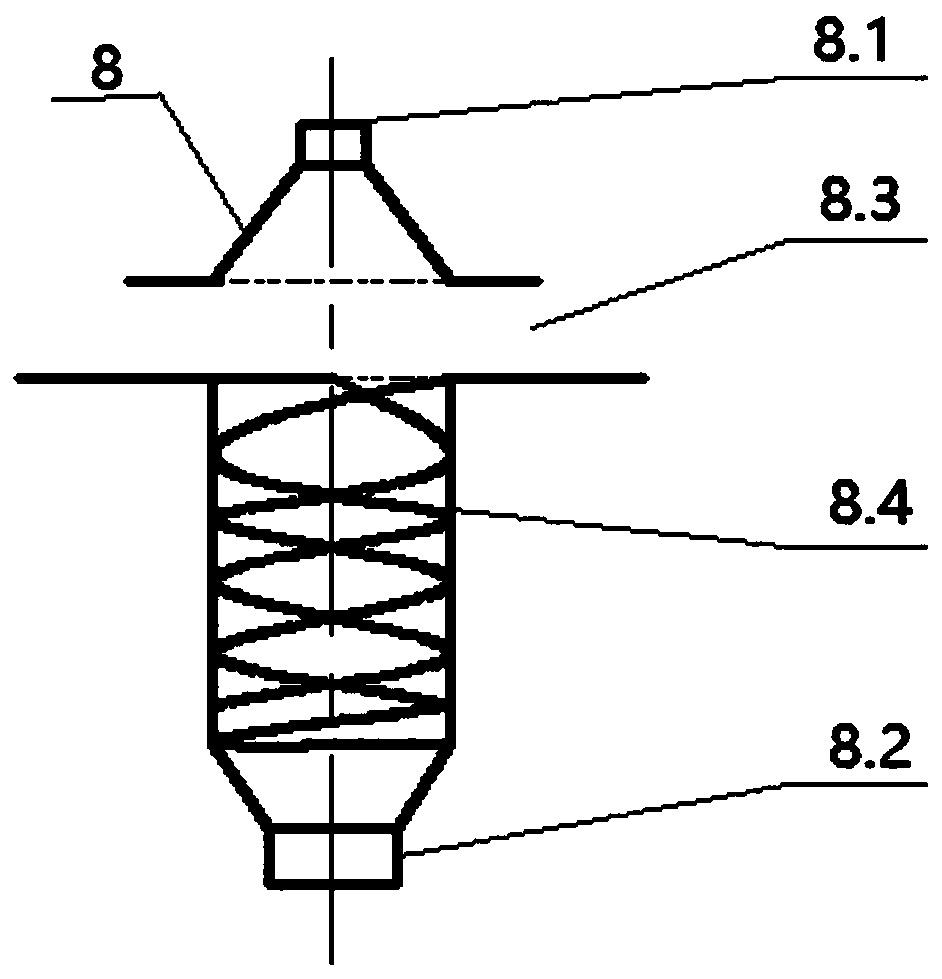

[0022] see Figure 1 to Figure 3 , a screening and drying device, comprising a housing 1, a screening cylinder 2, a conveying device, a separation cylinder 8, a heating box 9, a combustion chamber 10, a suction fan 11 and a protective cover 3; one end of the housing is connected with a screening cylinder, And the housing is provided with a feed port and an impurity discharge port connected to the screening cylinder, and the feed port and the impurity discharge port are respectively connected with a feeding pipe 1.1 and an impurity discharge pipe 1.2; A hole 2.1, and the screening cylinder is provided with a spiral guide bar 2.2 and a rotating shaft 4; the other end of the housing is connected with a conveying device; the conveying device includes a two-way...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com