Valve body cleaning device

A cleaning device and valve body technology, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as poor cleaning effect and inability to remove impurities on the surface of the valve body, so as to avoid Clean the dead angle, improve the matching effect, and ensure the effect of the limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

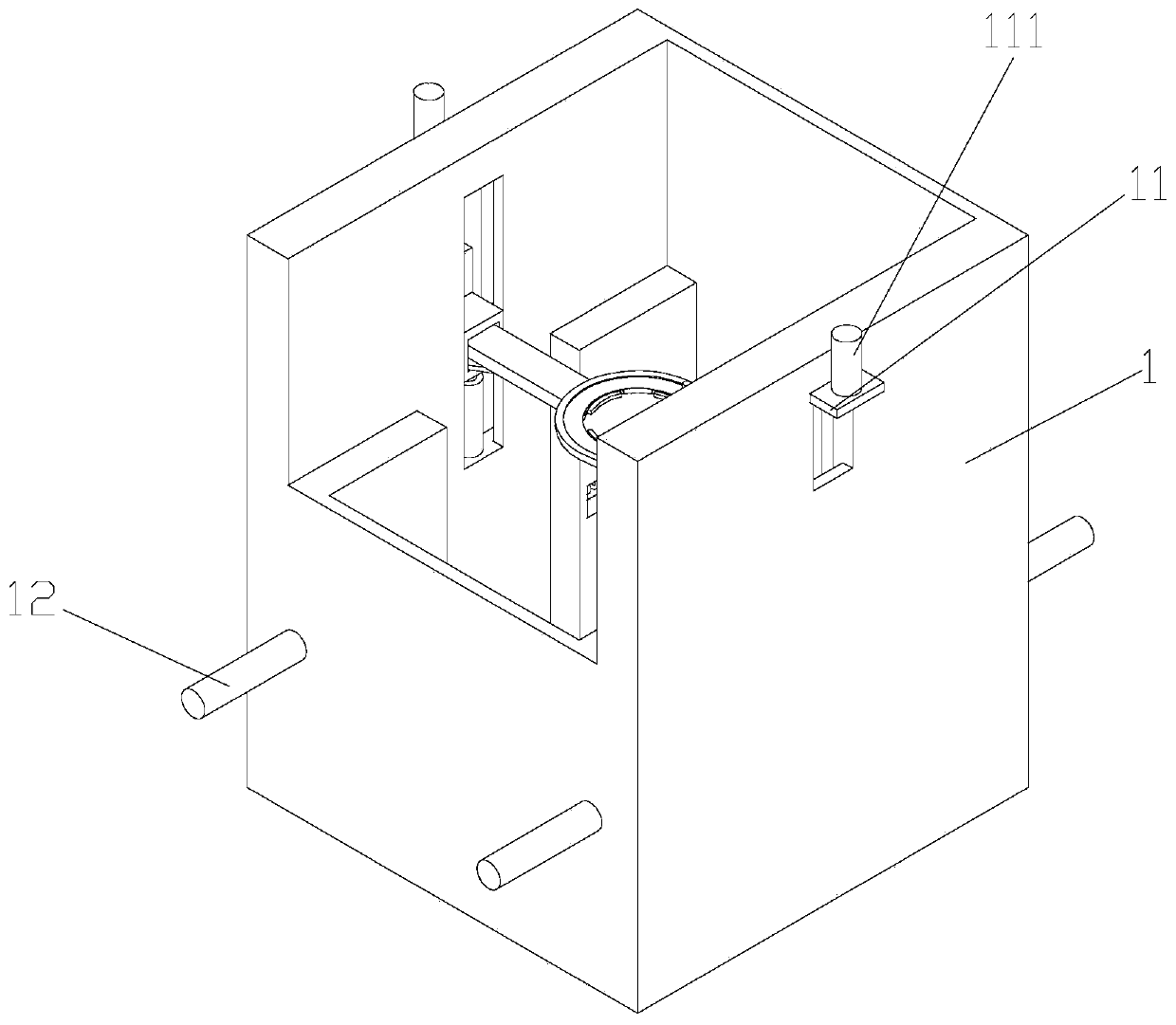

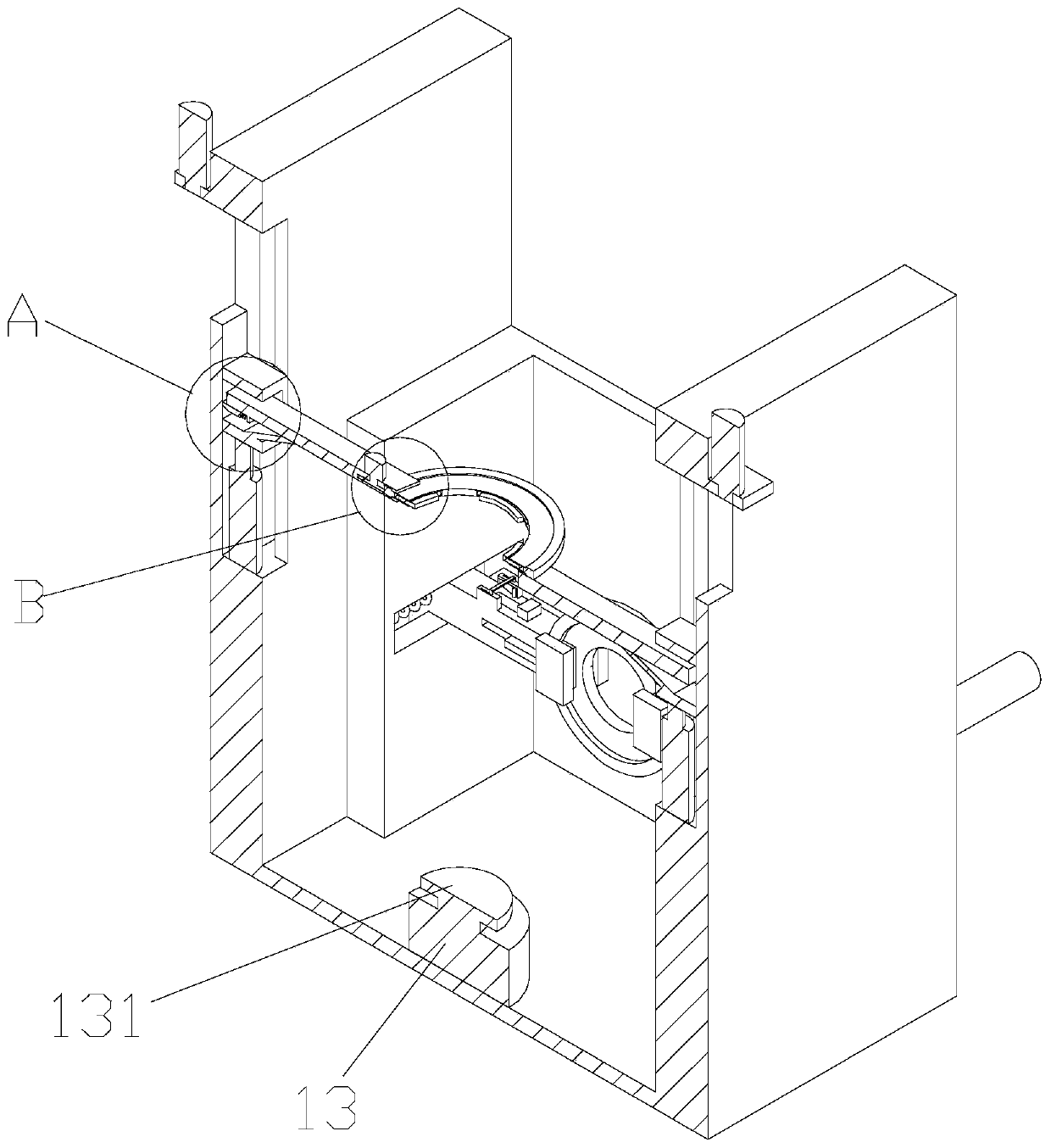

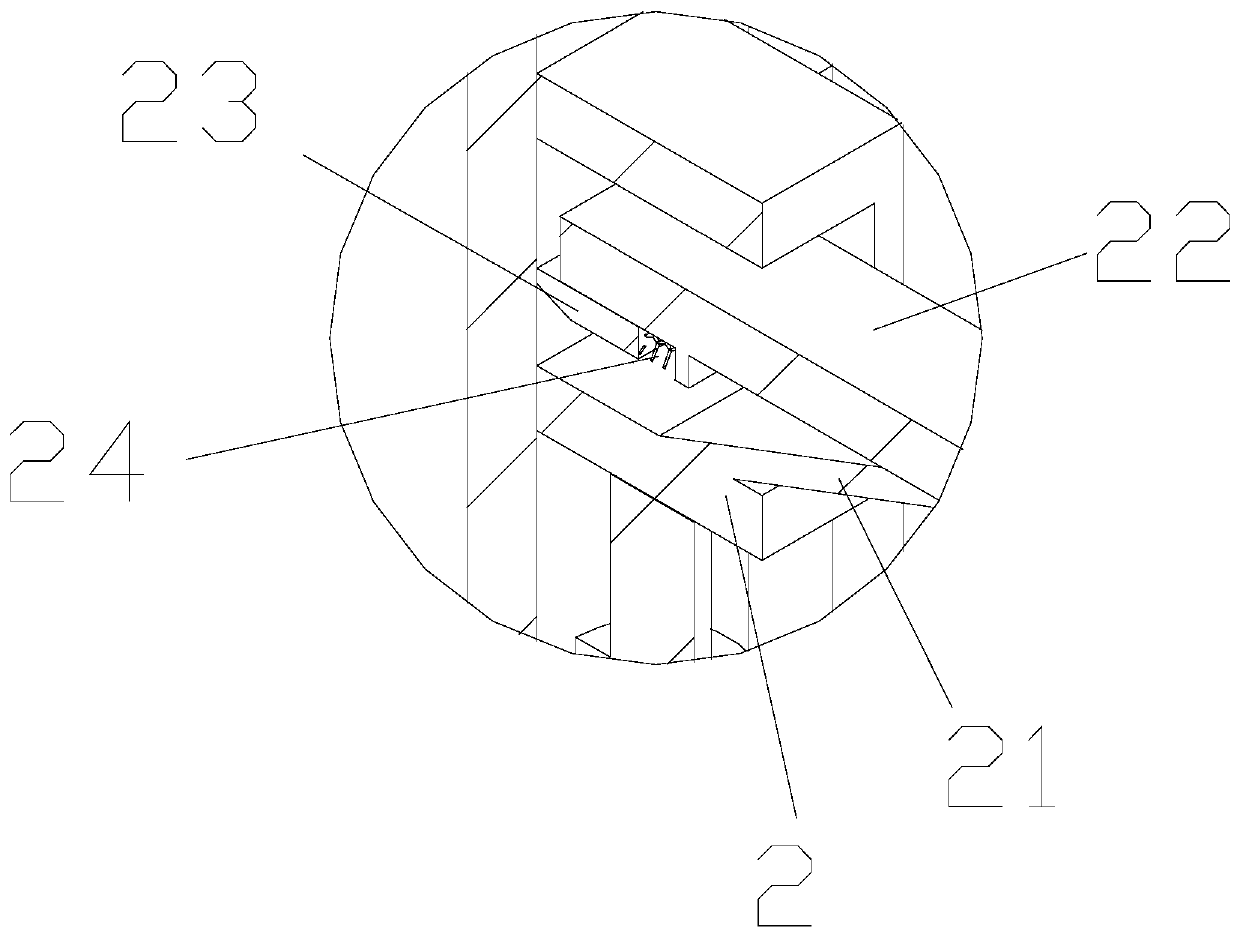

[0033] Such as Figure 1-17 As shown, a valve body cleaning device includes a cleaning box 1, a fixing assembly arranged in the cleaning box 1 and a cleaning assembly arranged in the cleaning box 1, and the inner wall of the cleaning box 1 is provided with Mounting block 14, described mounting block is four, is symmetrically arranged on the inner wall of described cleaning box, is provided with first movable groove on described mounting block 14, is provided with first movable block 3 in described first movable groove The side wall of the cleaning box 1 is provided with a first cylinder 12 matched with the first movable block 3, and the cleaning assembly includes a first connecting rod 33 arranged on the first movable block 3, which can Rotate the collar 32 that is located on the first connecting rod 33 and the first driving motor that is located on the first connecting rod 33, the first driving motor can drive the collar 32 to rotate, the collar A plurality of bristles are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com