Turnover mechanism of engraving and milling machine

A technology of turning mechanism and engraving and milling machine, which is applied in the direction of multi-purpose machinery, forming/shaping machine, special forming/shaping machine, etc. It can solve problems such as difficult to realize efficient automatic processing, and achieve the effect of simplifying moving components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

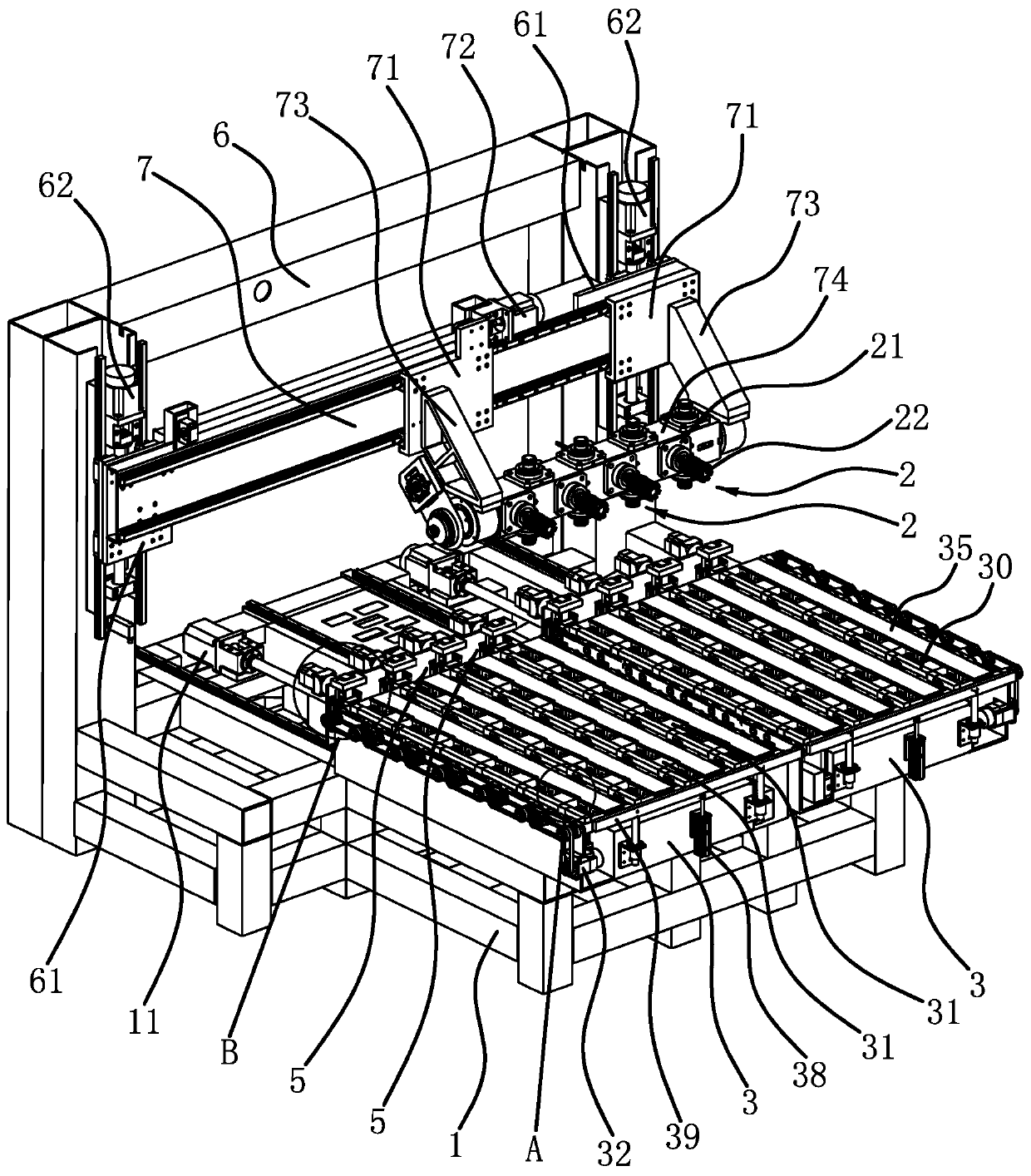

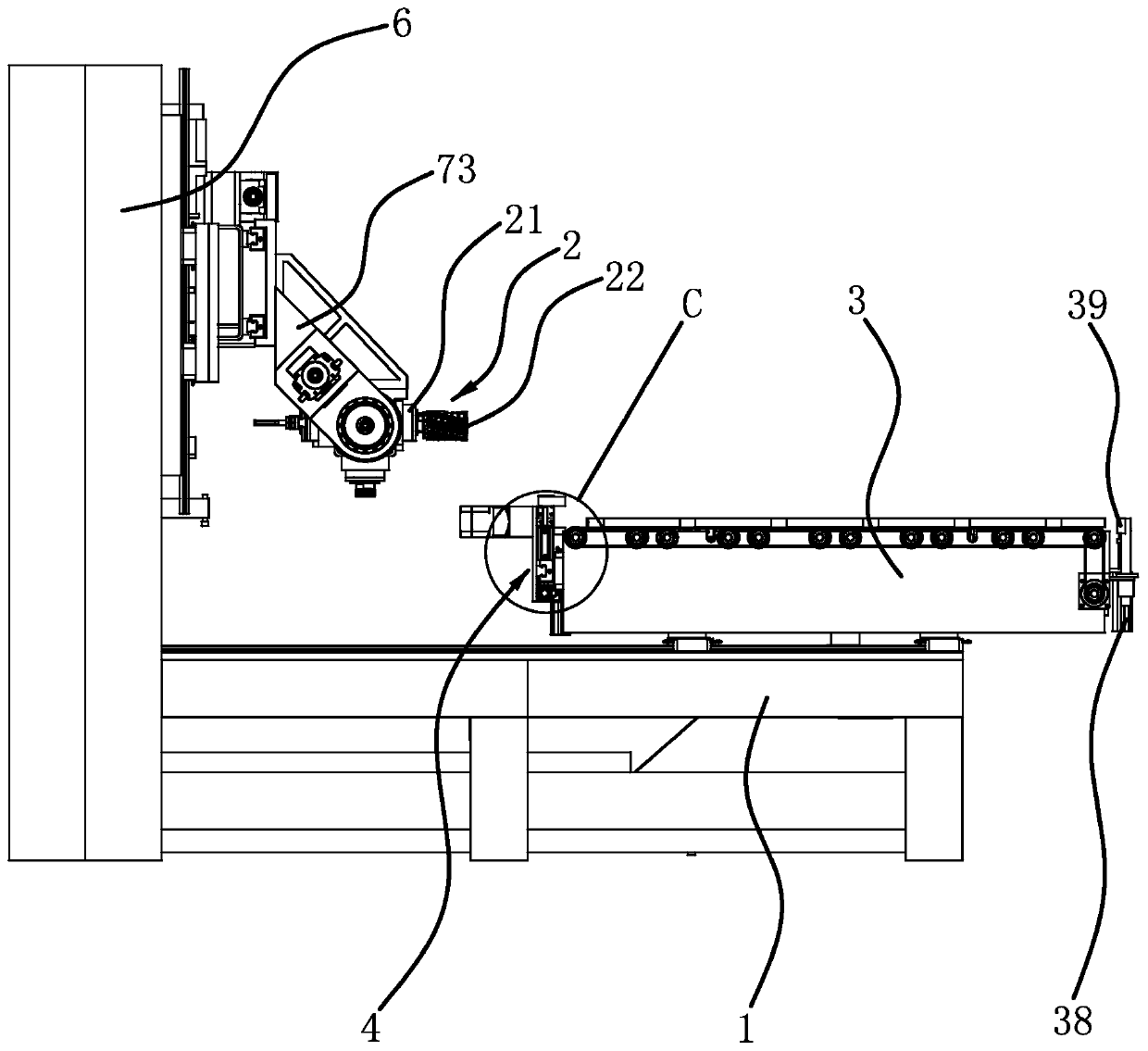

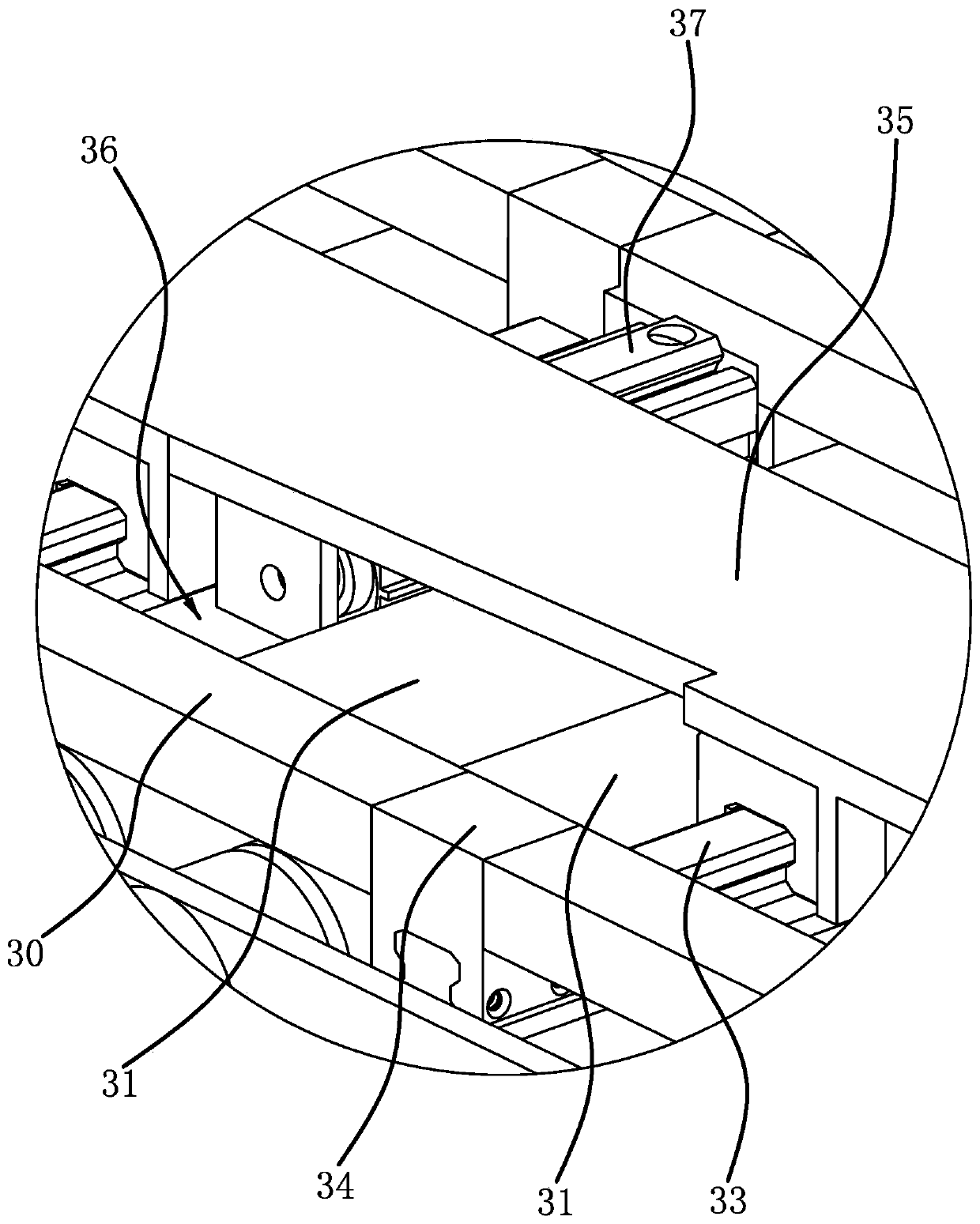

[0032] Such as figure 1 , figure 2 As shown, the turning mechanism of the engraving and milling machine, the engraving and milling machine includes a frame 1, a processing component 2 and a processing platform 3, a gantry 6 is fixed on the frame 1, and the two columns of the gantry 6 are vertically slid and connected with vertical The carriage 61 is fixed with a crossbeam 7 arranged horizontally between the two vertical carriages 61. The crossbeam 7 is driven vertically through the cooperation of the vertical motor 62 and the screw nut assembly. Plate 71, the horizontal drag plate 71 is driven horizontally through the cooperation of the horizontal motor 72 and the screw nut assembly. The horizontal drag plate 71 has two pieces, and each horizontal drag plate 71 is fixed with a support seat 73, between the two support seats 73 There is a strip-shaped tool holder 74 that is rotatably connected to each other, and the tool holder 74 is arranged laterally. There are multiple proc...

Embodiment 2

[0037] The turning mechanism of the engraving and milling machine is basically the same as the structure of the first embodiment, the difference is that Figure 7 As shown, the gantry 6 is slidingly connected to the frame 1 in the longitudinal direction, and the longitudinal motor 11 cooperates with the screw nut assembly to drive the gantry 6 to move in the longitudinal direction. Correspondingly, the processing platform 3 only needs to be fixed on the frame 1 That is, at this time, the moving assembly 4 can be set on the processing platform 3 or directly on the frame 1 .

Embodiment 3

[0039] The turning mechanism of the engraving and milling machine is basically the same as the structure of the first embodiment, the difference is that Figure 8 As shown, clamps 5 all include rotary cylinders 57, and several rotary cylinders 57 are fixed on the moving plate 41 and arranged horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com