Vibrating feeder

A vibrating feeder and vibrating bar technology, which is applied in the field of mining machinery, can solve the problem of low screening efficiency of stone impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

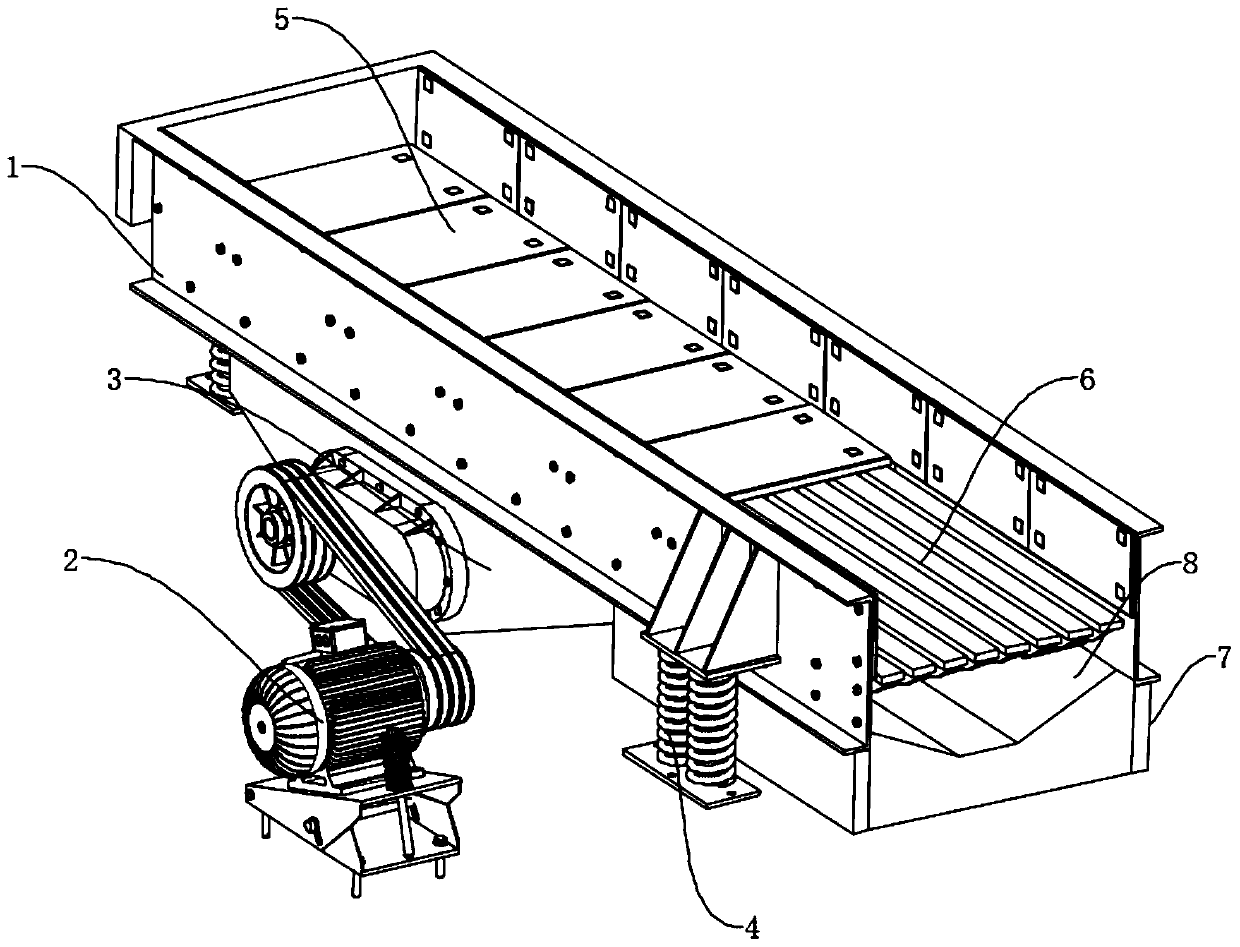

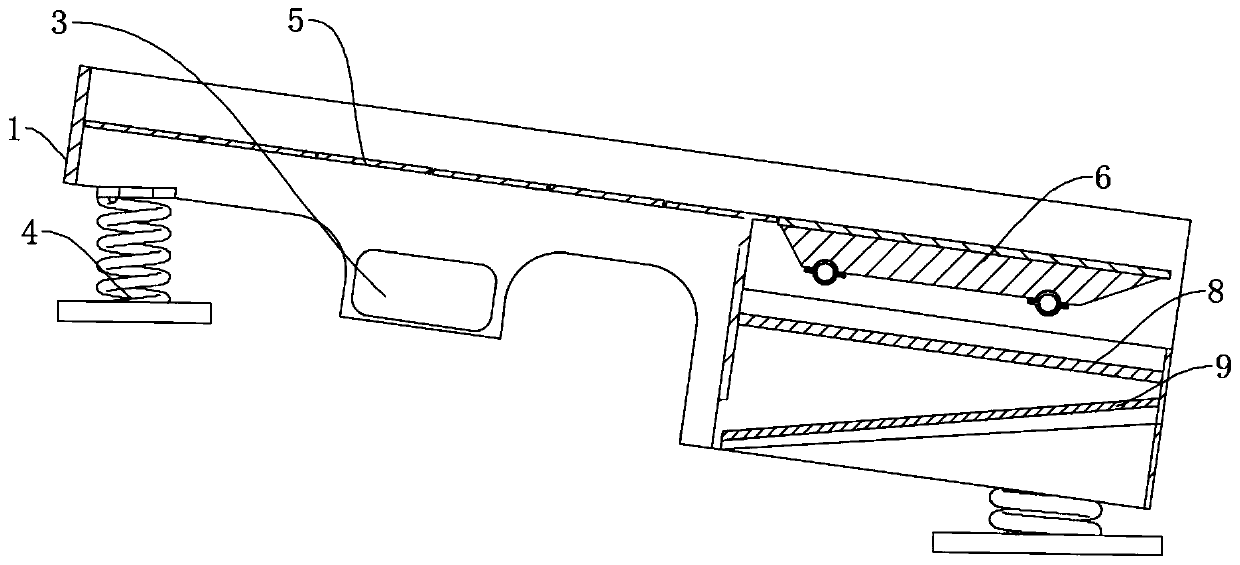

Embodiment 1

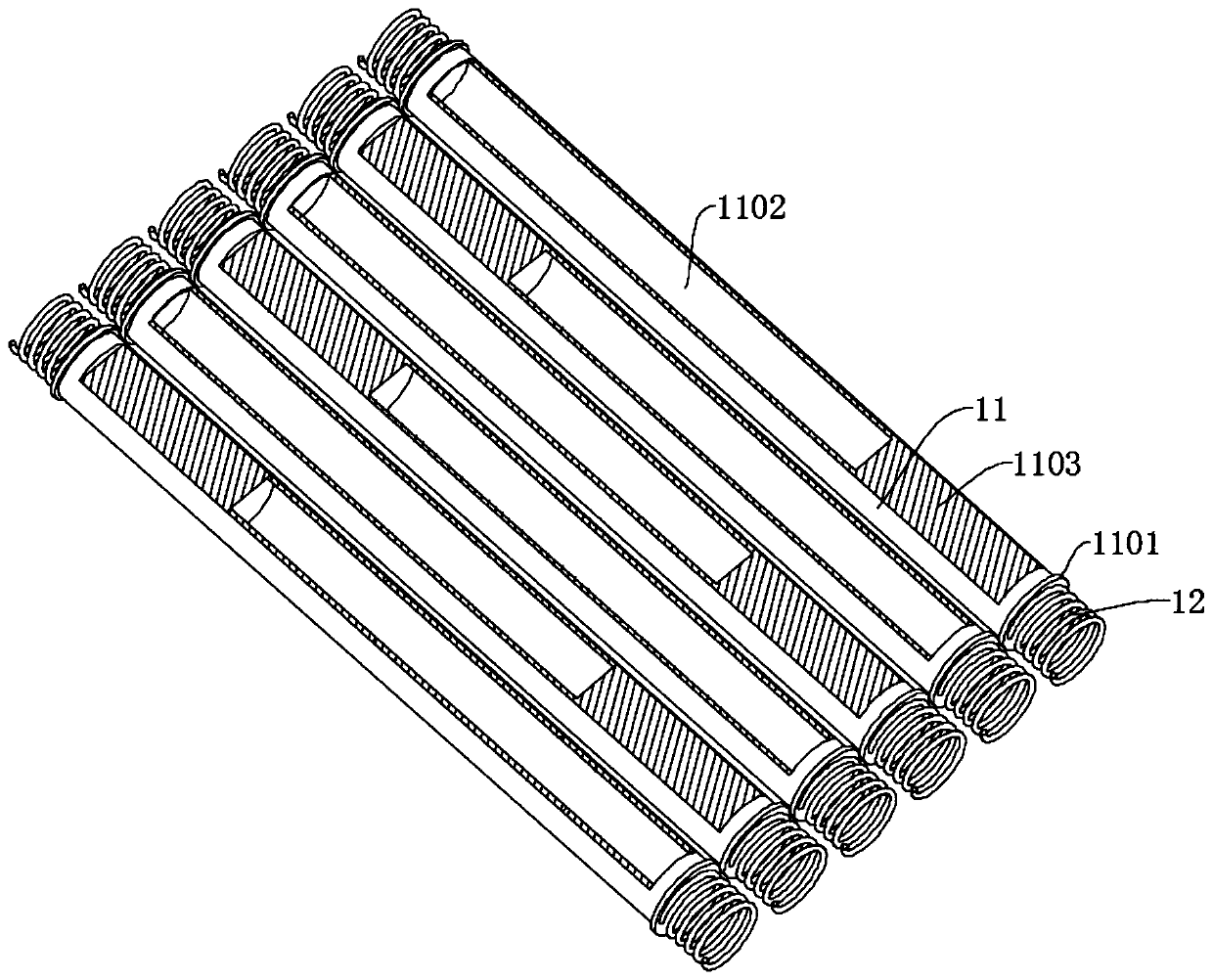

[0027] The frame 1 is provided with a sieve plate 6 and a combined screening device; the combined screening device is provided with two layers of sieving plates, and is located below the sieve plate 6; the vibrating bar 11 is also installed in the sieving plate, and the vibrating bar 11 It can move axially; and the vibrating bar 11 includes a solid segment 1102 and a hollow segment 1103 , and the solid segments 1102 and hollow segments 1103 of two adjacent vibrating bars 11 are alternately arranged. The frequency conversion motor inside the driving device 3 outside the frame 1 works, and the kinetic energy is transmitted to the vibrator 2 through the pulley mechanism, and the vibrator 2 is driven by a biaxial eccentric to make the device generate vibration force, driving the entire frame 1 to vibrate; Put it into the inclined blanking plate 5, the stone will slide down on the upper end of the sieve plate 6 along the blanking plate 5, and the impurities will fall on the sieve pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com