Quickly prefabricated corridor for steel structure elevator

A steel structure, prefabricated technology, applied in building construction, building maintenance, construction, etc., can solve problems such as affecting residents' experience, prolonging the construction period of shaft projects, and increasing the difficulty of hoisting, so as to facilitate daily travel and shorten projects. The effect of reducing the construction period and reducing the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

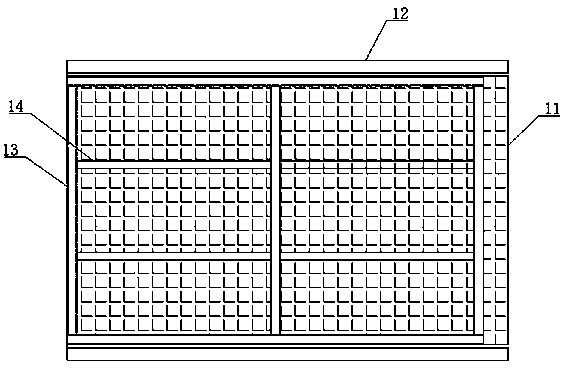

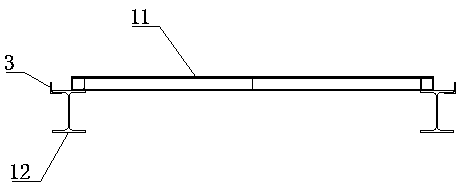

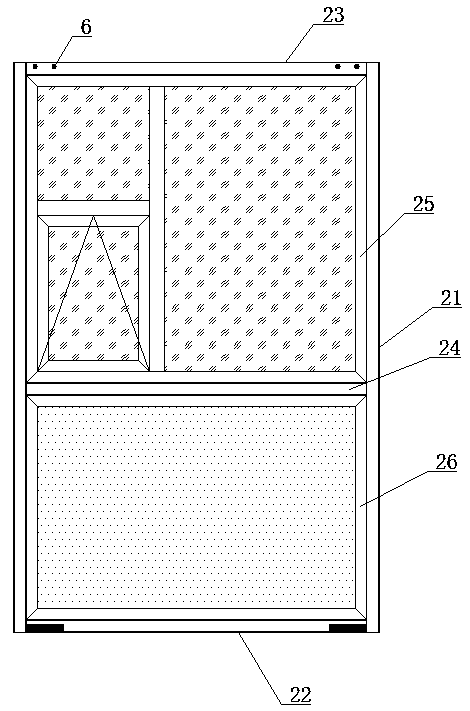

[0031] like Figure 1 to Figure 6 As shown, a quick-assembled corridor for a steel structure elevator includes a corridor bottom plate 1 and two corridor side plates 2. The bottom plate 1 is fixedly installed on the pre-embedded plate of the building and the main body of the steel structure shaft. Each corner is provided with a first connecting corner piece 3 , the side plate 2 is symmetrically installed above the bottom plate 1 through the first connecting corner piece 3 , and the top of the side plate 2 is fixedly connected to the upper bottom plate 5 through the second connecting corner piece 4 .

[0032] like figure 1 and figure 2 As shown, the base plate 1 includes a base plate frame and an upper deck board 11, and the upper deck board 11 is installed above the base plate frame.

[0033] The baseplate frame includes:

[0034] Two oppositely arranged bottom plate steel beams 12, and the first connecting angle piece 3 is installed on both ends of the bottom plate steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com