Sound energy compressor cycle structure

A cycle structure and compressor technology, applied in the field of compressors, can solve problems affecting system stability, work efficiency, friction loss, etc., and achieve the effects of excellent heat dissipation, reduced stress concentration, and high cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

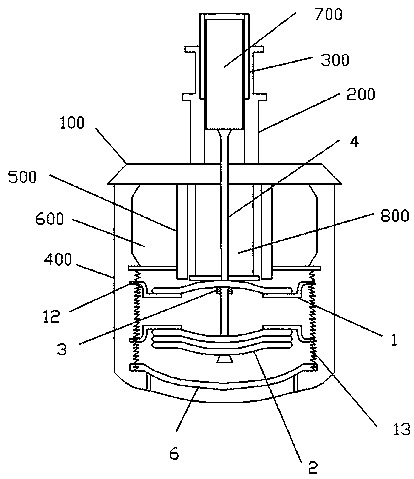

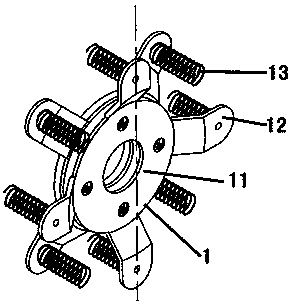

[0029] An acoustic energy compressor cycle structure, such as Figure 1-4 As shown, the upper side of the connection base 100 is provided with an expansion chamber 300 through an external fixing ring 200, the connection base 100 is coaxially fixed with an outer shell 400 and a power cylinder 500 from the outside to the inside, and the expansion piston 700 is inside the expansion chamber 300 reciprocating motion.

[0030] There is also a copper heat dissipation part on the external fixing ring, which has a better heat dissipation effect.

[0031] The outside of the power cylinder 5 is provided with a coil structure 600. This coil structure is adopted with reference to the coil structure in the existing sound energy compressor. Its purpose is to cooperate with the power piston. When the power is on, a magnetic field is generated to make the power piston 800 in the power cylinder reciprocate. sports.

[0032] The expansion piston passes at its underside through the power piston...

Embodiment 2

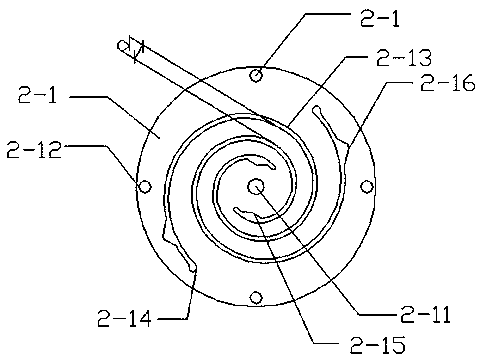

[0047] The width of the back-shaped hollow grooves 2-13 is 11mm, and the groove body spacing d between adjacent round-shaped hollow grooves 2-13 is set to gradually increase outwards, and the innermost groove body spacing d is 4mm, specifically d+0.4 The dimensions in mm are increased.

Embodiment 3

[0049] The width of the back-shaped hollow grooves 2-13 is 8mm, and the groove body spacing d between adjacent round-shaped hollow grooves 2-13 is set to gradually increase outwards, and the innermost groove body spacing d is 4mm, specifically d+0.8 The dimensions in mm are increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com