Device and method for detecting integrity of CT secondary circuit

A secondary loop and integrity technology, applied in measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as on-off measurement of multimeters with poor contact, so as to facilitate fault finding, reduce the risk of poor contact, and reduce heat generation. The effect of the risk of burning the terminals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

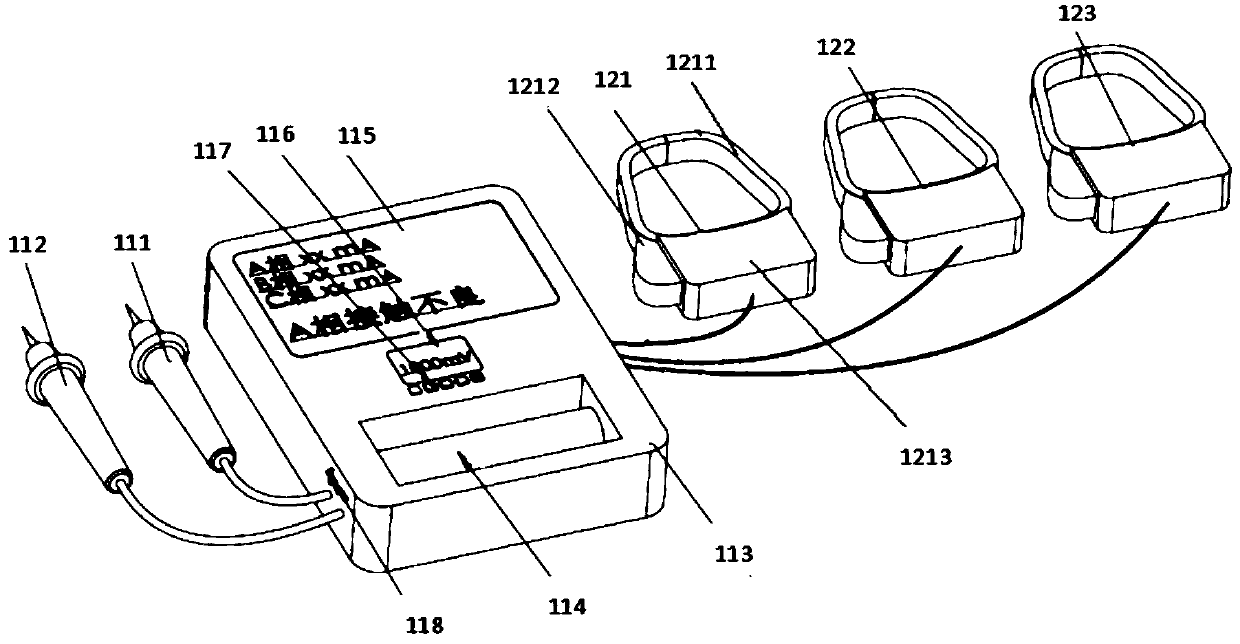

[0062] like figure 1 As shown, the main device 1 includes a host 11, a current clamp meter 12 and an adjustable DC voltage source 13; wherein:

[0063] The current clamp 12 includes an A-phase current clamp 121, a B-phase current clamp 122 and a C-phase current clamp 123; the current clamp 12 is electrically connected to the host 11; the adjustable DC voltage source 13 is connected to the CT secondary circuit to provide voltage for the entire secondary circuit detection circuit.

[0064] The host 11 includes a DC output positive test lead 111, a DC output negative test lead 112, a housing 113, a storage battery 114, a result output display screen 115, a DC output display screen 116, a power adjustment button 117 and an output positive and negative sign 118; wherein:

[0065] The DC output positive test lead 111 and the DC output negative test lead 112 are electrically connected to the circuit module; the battery 114, the result output display screen 115, the DC output display s...

Embodiment 2

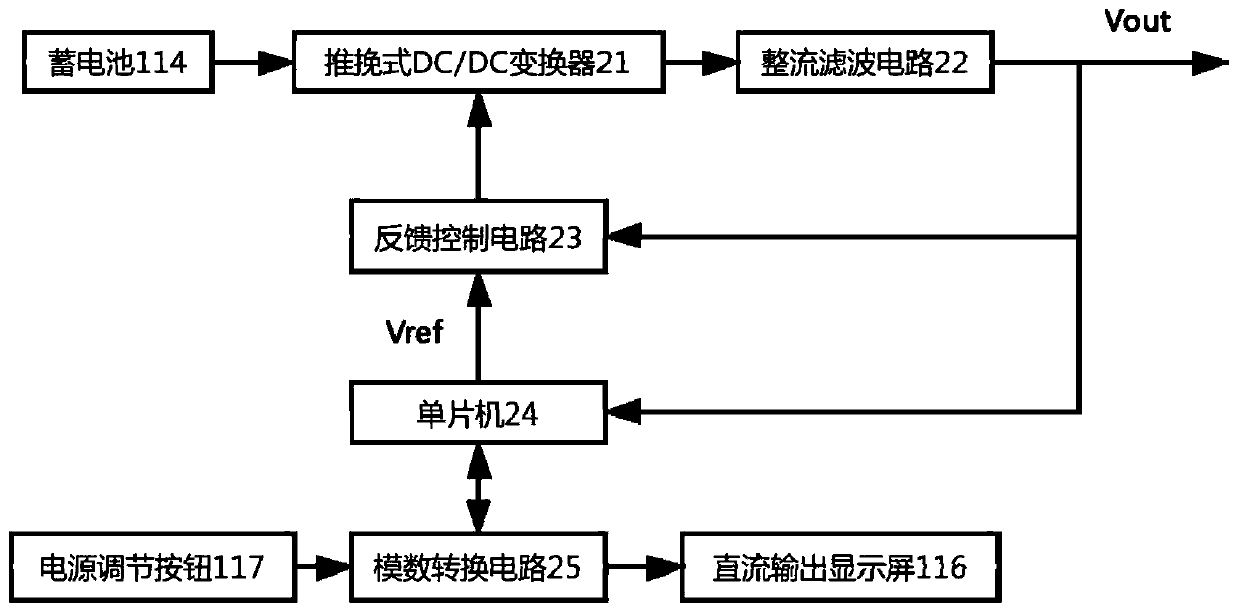

[0070] like figure 2 As shown, the circuit module 2 includes a push-pull DC / DC converter 21, a rectification filter circuit 22, a feedback control circuit 23, a single-chip microcomputer 24 and an analog-to-digital conversion circuit 25; wherein: the push-pull DC / DC converter 21 output terminals are electrically connected to the input terminals of the rectification filter circuit 22; the output terminals of the rectification filter circuit 22 are respectively electrically connected to the input terminals of the single-chip microcomputer 24 and the input terminals of the feedback control circuit 23; the output terminals of the single-chip microcomputer 24 end is electrically connected to the input end of the feedback control circuit 23; the output end of the feedback control circuit 23 is electrically connected to the input end of the DC / DC converter 21; the single-chip microcomputer 24 is electrically connected to the analog-to-digital conversion circuit 25 sexual connection....

Embodiment 3

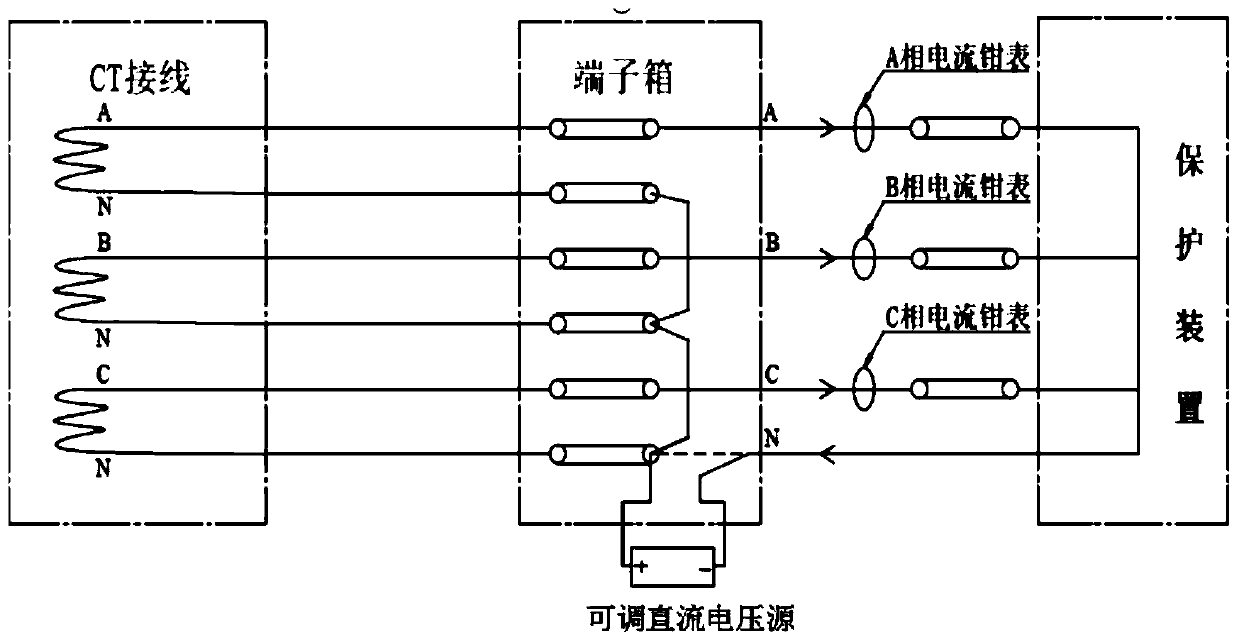

[0075] like image 3 As shown, each group of CT secondary circuits includes ABCN phases, and the CTs connected in series to primary equipment have multiple secondary windings, which are divided into groups such as protection, measurement and control, and measurement according to functions. The CT secondary circuits pass through the CT secondary junction box It is introduced into the terminal block of the field terminal box through underground cables, and then connected to the protection and measurement and control devices in the protection room. The resistance of the circuit from the secondary side of the CT to the disconnected phase is about 0.5Ω, and the resistance from the terminal box to the protection, measurement and control device is even smaller, within 0.2Ω. The same-named ends of the ABC three-phase windings are respectively connected to the protection device, and then flow back through the N-phase to form a complete circuit. The N-terminals of the three-phase windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com