Concrete beam nonlinear model correction method based on response surface method

A technology of nonlinear model and response surface model, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as stress state and later performance prediction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

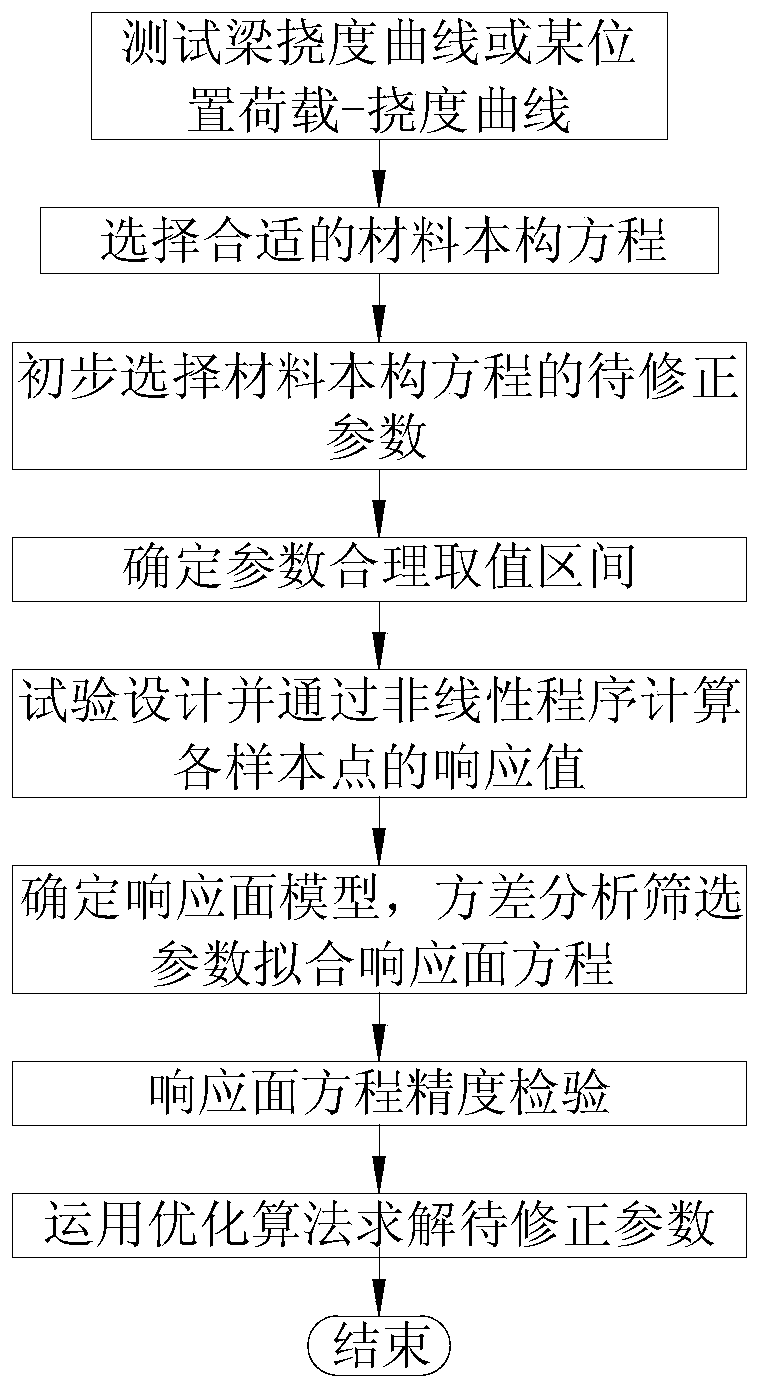

Method used

Image

Examples

Embodiment 1

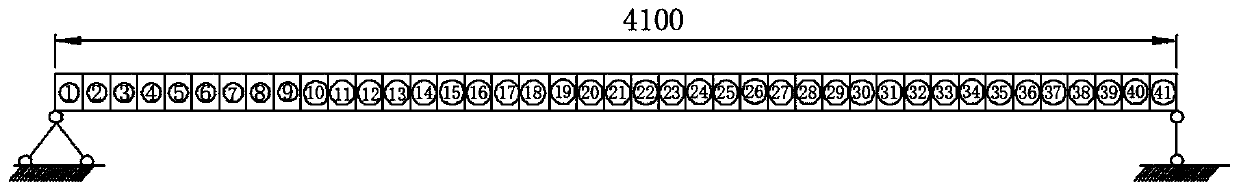

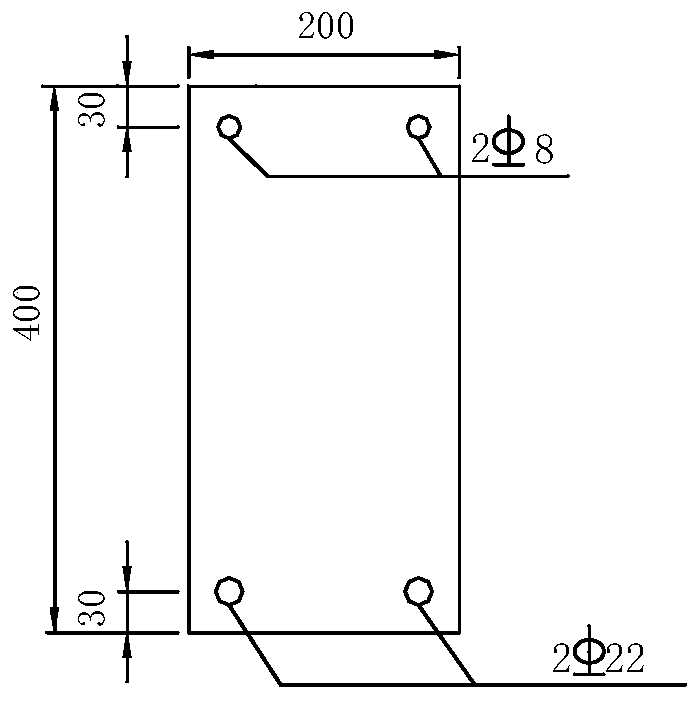

[0055] Embodiment 1: Take a reinforced concrete simply supported beam as an example, such as figure 2 , image 3 As shown, the section size of the simply supported beam is 200mm×400mm, the calculated span is 4.1m, the concrete strength grade is C30, the ordinary steel bar under the force adopts the ribbed steel bar with a diameter of 22mm and HRB335, and the structural steel bar uses a diameter of 8mm, HRB335 Ribbed steel bar, the grid division size is 10cm, a total of 41 units are divided.

[0056] In actual engineering, due to the influence of on-site construction technical conditions, gradual aging of materials, and the decline of effective stress caused by prestress relaxation, the design values and actual values of parameters such as material density, elastic modulus, and component geometric dimensions often exist. Certain difference. Considering that ordinary reinforced concrete structures are very easy to crack and most of them work with cracks, this example anal...

Embodiment 2

[0118] Embodiment two: take a prestressed reinforced concrete beam as an example, as Figure 4 As shown, the calculated span of the prestressed concrete simply supported beam is 8m, the cross-sectional size is 300mm×500mm, the strength grade of the concrete is C50, the ordinary tensile steel bar adopts HRB335 ribbed steel bar with a diameter of 14mm, and the structural steel bar adopts a diameter of 10mm HRB335 ribbed steel bar, the prestressed steel bar adopts the standard tensile strength value of 1860MPa, and the nominal diameter is the prestressed steel bar of 15.24mm, and the grid division size of the simply supported beam in this embodiment is 10cm.

[0119] The specific implementation steps are as follows:

[0120] Step 1: Obtain the measured deflection curve under the load of 40kN in the mid-span of the beam and the measured load-deflection curve under the stepwise loads of 10kN, 20kN, 30kN, 40kN, 50kN, and 60kN in the mid-span of the beam through the static test.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com