Mechanical sealing testing device and method for experimental teaching

A mechanical seal device and mechanical seal technology, applied in teaching models, educational appliances, instruments, etc., can solve problems such as troublesome disassembly, unfavorable experimental teaching, lack of versatility, etc., to facilitate repair and maintenance, improve versatility, The effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

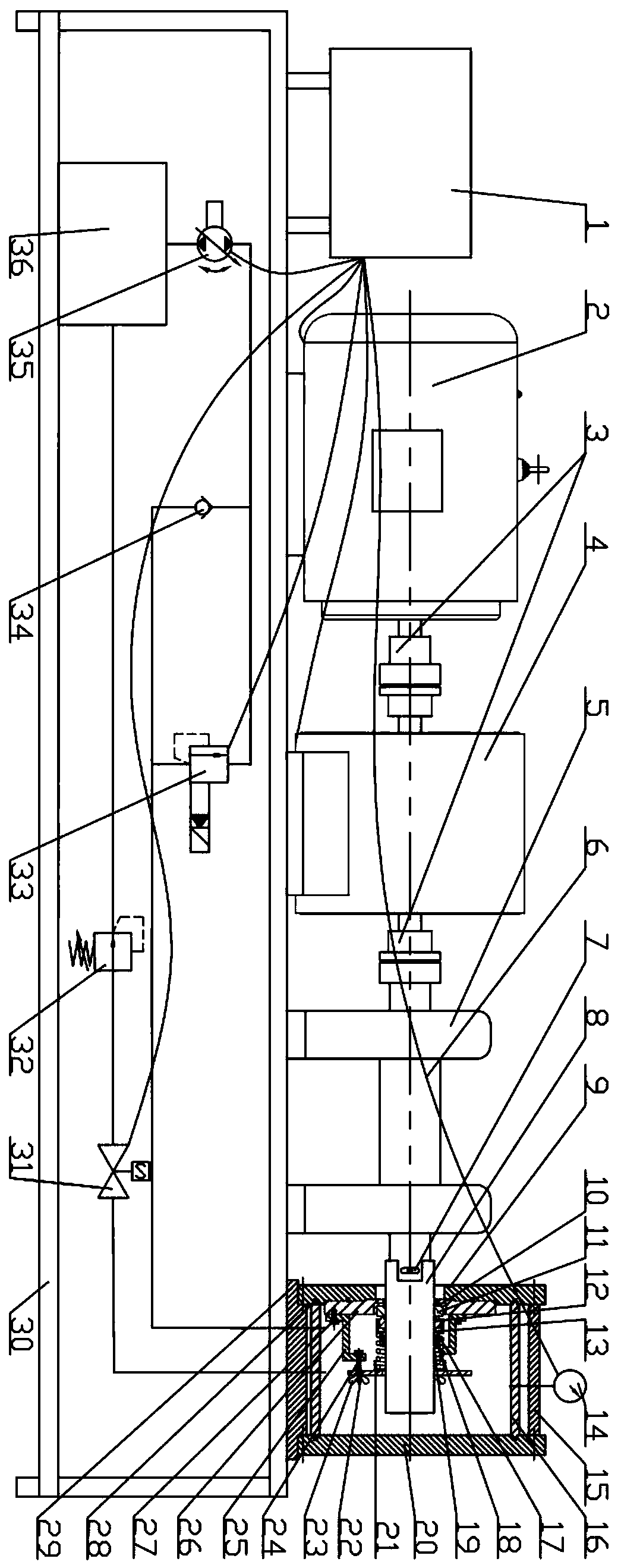

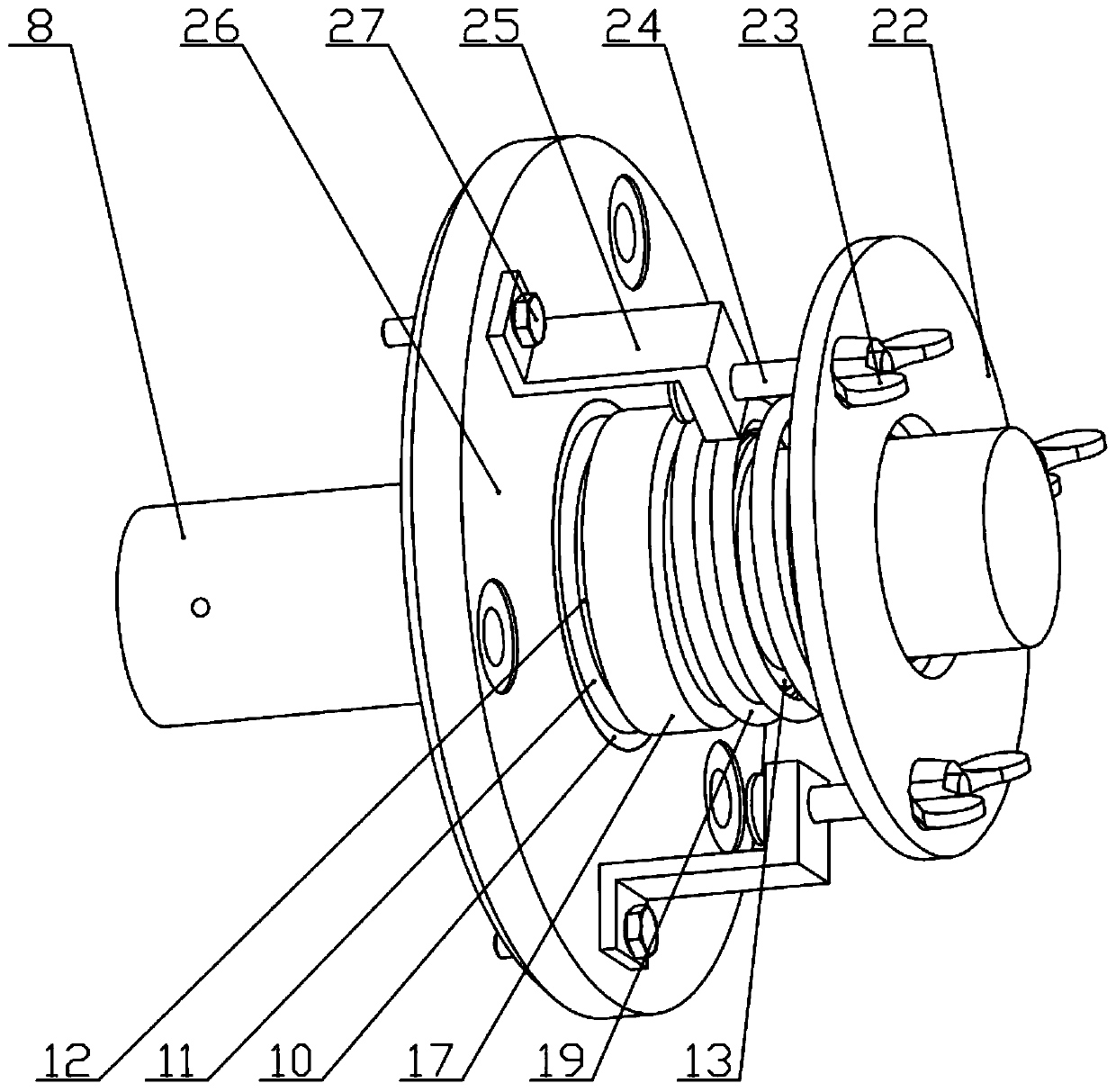

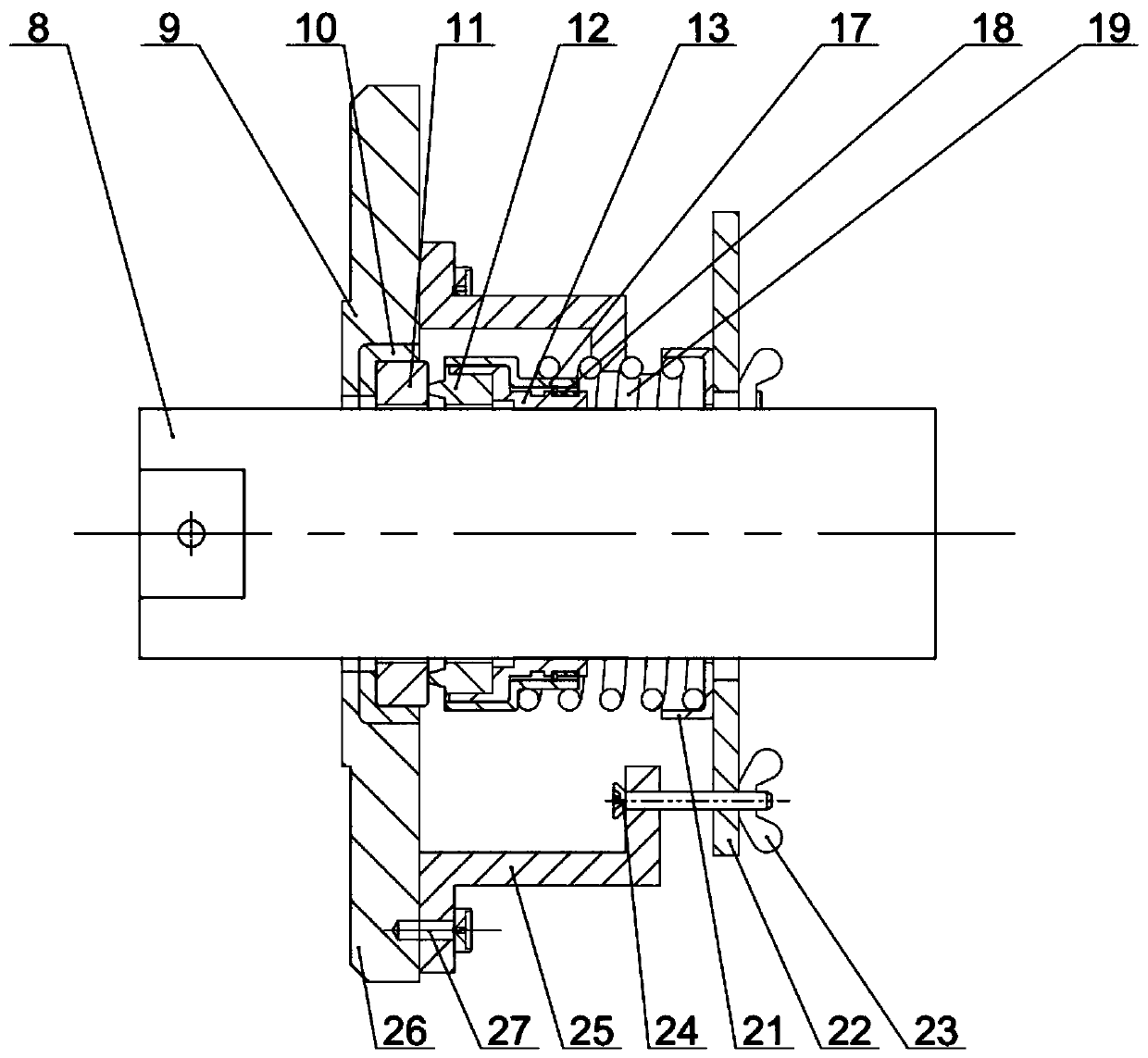

[0041] Such as figure 1 As shown, a mechanical seal test device for experimental teaching, including a bench 30, a computer 1, a motor 2, a torque speed measuring instrument 4, a bearing seat 5, a transmission shaft 6, a sealing cavity, an oil tank 36, and a two-way hydraulic pump 35 , pipeline; the stand 30 is divided into upper and lower layers, the upper layer is used to install the computer, the motor 2, the torque speed measuring instrument 4, the bearing seat 5, the transmission shaft 6, the sealed cavity, the motor 2 and the torque speed measuring instrument 4. The torque speed measuring instrument 4 and the transmission shaft 6 are respectively connected by a coupling 3. The rightmost end of the transmission shaft 6 is a square convex key, and the axial center of the convex key is provided with a through hole for installing the cotter pin 7. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com