Quickly-charged lithium ion battery negative plate and preparation method thereof

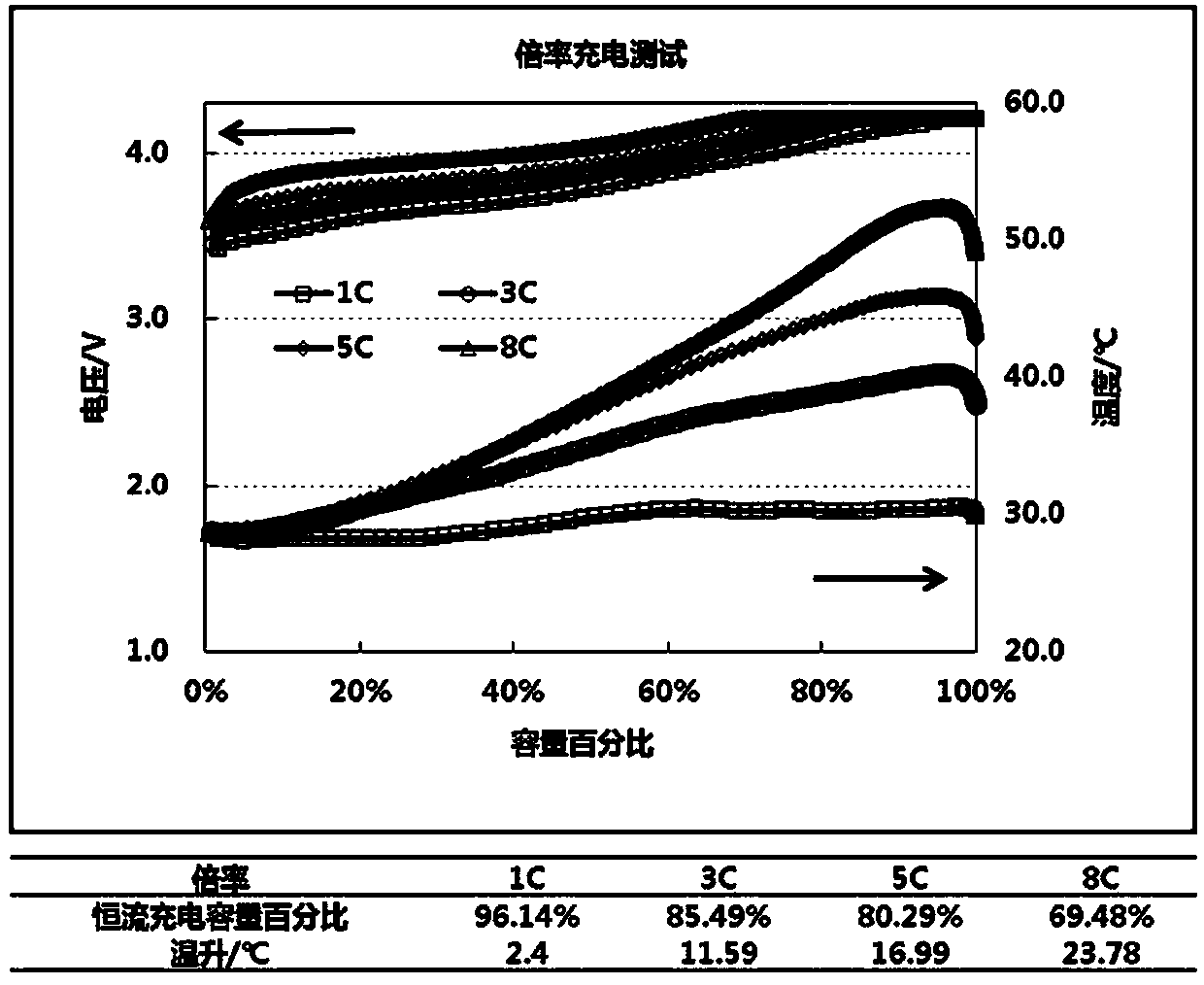

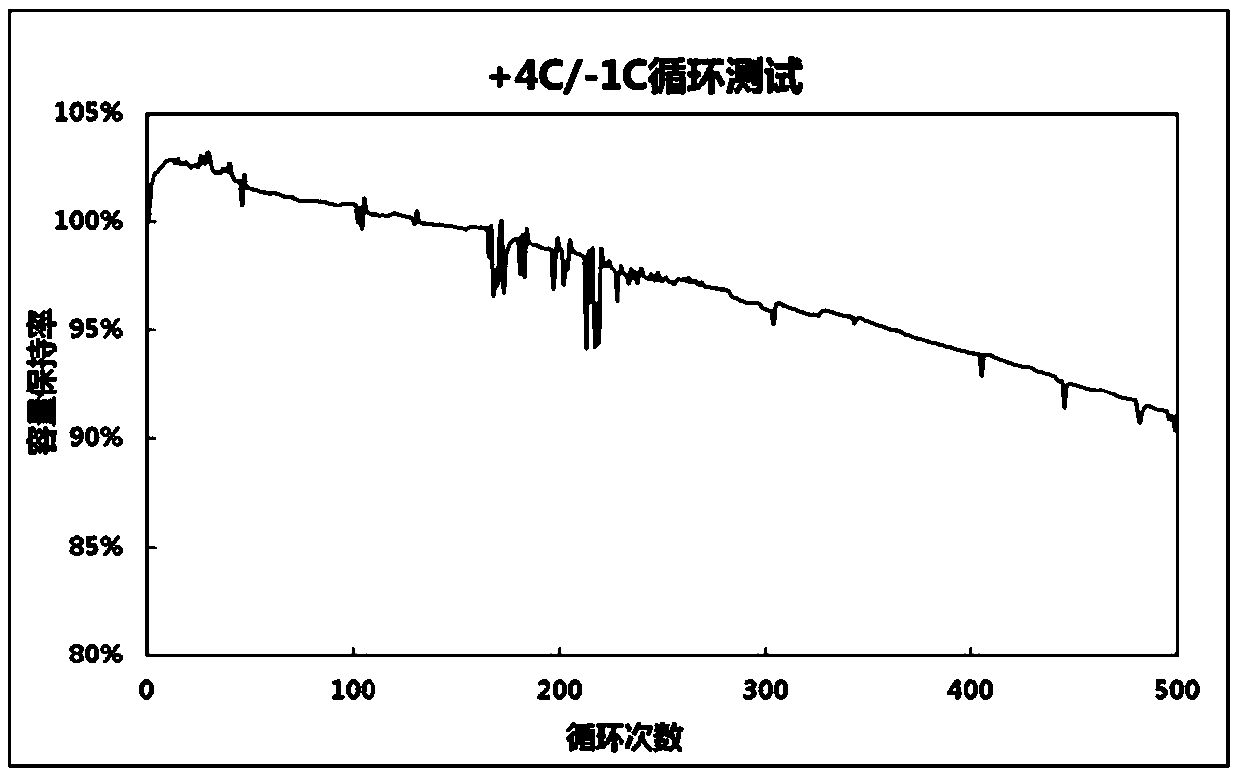

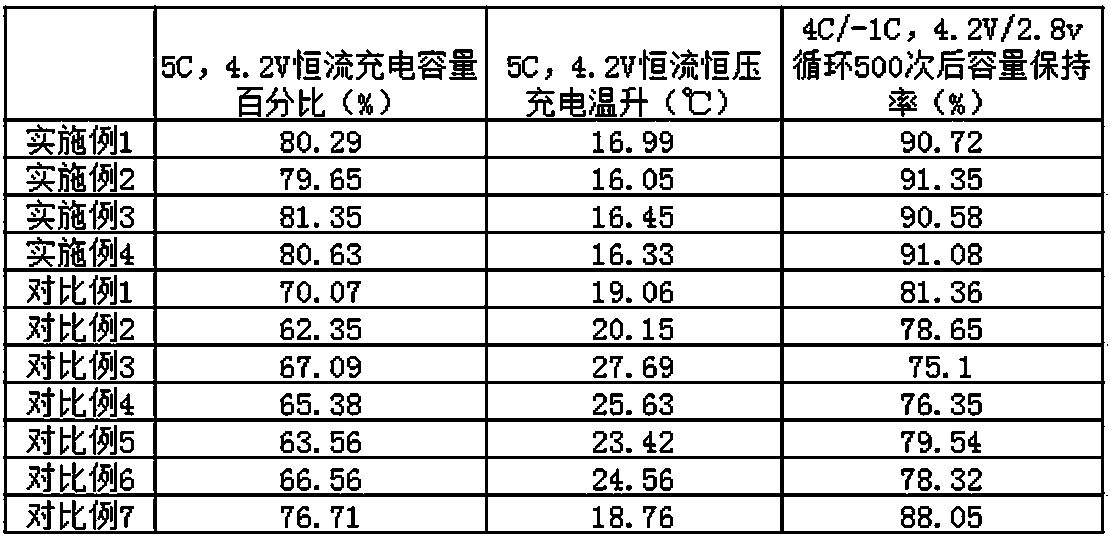

A lithium-ion battery, fast charging technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve problems such as reduction, and achieve the effects of low temperature rise, battery temperature rise control, and improved liquid absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In a second aspect, the present invention also provides a method for preparing the negative electrode sheet of the above-mentioned fast-charging lithium-ion battery, comprising the steps of:

[0048] S1. Add 70-75 parts of deionized water and 1-2 parts of thickener into the blender, stir until the thickener is fully dissolved, remove air bubbles in a vacuum, and prepare glue for use;

[0049] S2. Stir 70-73 parts of the first artificial graphite, 21-25 parts of the second artificial graphite, and 1-2 parts of conductive agent to obtain powder;

[0050] S3. Add 20% of the total mass of the glue prepared in step S1 to the above powder, and stir until the powder is dispersed into granules;

[0051] S4. Add 50% of the total mass of the glue prepared in step S1 to the slurry prepared in step S3, and stir until the particles are kneaded with each other;

[0052] S5. Add 30% of the glue solution gross mass that step S1 makes to the slurry that step S4 makes, stir;

[0053] S...

Embodiment 1

[0063] A lithium-ion battery negative electrode sheet for rapid charging, the preparation method of which comprises the steps of:

[0064] S1. Add 72 parts of deionized water and 1.5 parts of thickener to a planetary mixer with a volume of 60L, stir at a revolution speed of 35rpm for 150 minutes until the thickener is fully dissolved, and remove air bubbles under a vacuum of less than -0.08 Mpa After 30 minutes, the glue solution was prepared and set aside;

[0065] S2. Add 71 parts of the first artificial graphite, 23 parts of the second artificial graphite, and 1.6 parts of conductive agent into a planetary mixer with a volume of 60 L, and stir for 30 minutes at a revolution speed of 20 rpm and a rotation speed of 200 rpm to obtain a uniformly mixed powder. Material; wherein, the particle diameter D50 of the first artificial graphite is 7 μm, and the particle diameter D50 of the second artificial graphite is 11 μm;

[0066] S3. Add 20% of the total mass of the glue prepared...

Embodiment 2

[0073] A lithium-ion battery negative electrode sheet for rapid charging, the preparation method of which comprises the steps of:

[0074] S1. Add 70 parts of deionized water and 1 part of thickener to a planetary mixer with a volume of 60L, stir at a revolution speed of 35rpm for 150 minutes until the thickener is fully dissolved, and remove air bubbles under a vacuum of less than -0.08 Mpa After 30 minutes, the glue solution was prepared and set aside;

[0075] S2. Add 70 parts of the first artificial graphite, 21 parts of the second artificial graphite, and 1 part of conductive agent into a planetary mixer with a volume of 60 L, stir for 30 minutes at a revolution speed of 20 rpm and a rotation speed of 200 rpm to obtain a uniformly mixed powder Material; wherein, the particle diameter D50 of the first artificial graphite is 6 μm, and the particle diameter D50 of the second artificial graphite is 10 μm;

[0076] S3. Add 20% of the total mass of the glue prepared in step S1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com