Permanent magnet motor structure and method capable of detecting permanent magnet demagnetization and rotor eccentricity faults

A technology for rotor eccentric and permanent magnet motors, which is applied to the shape/style/structure of winding conductors, motors, and measuring electronics. It can solve the problems of permanent magnet demagnetization and/or inaccurate detection of rotor eccentricity, and achieve convenient discovery and accuracy. Evaluation, simple operation, high feasibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

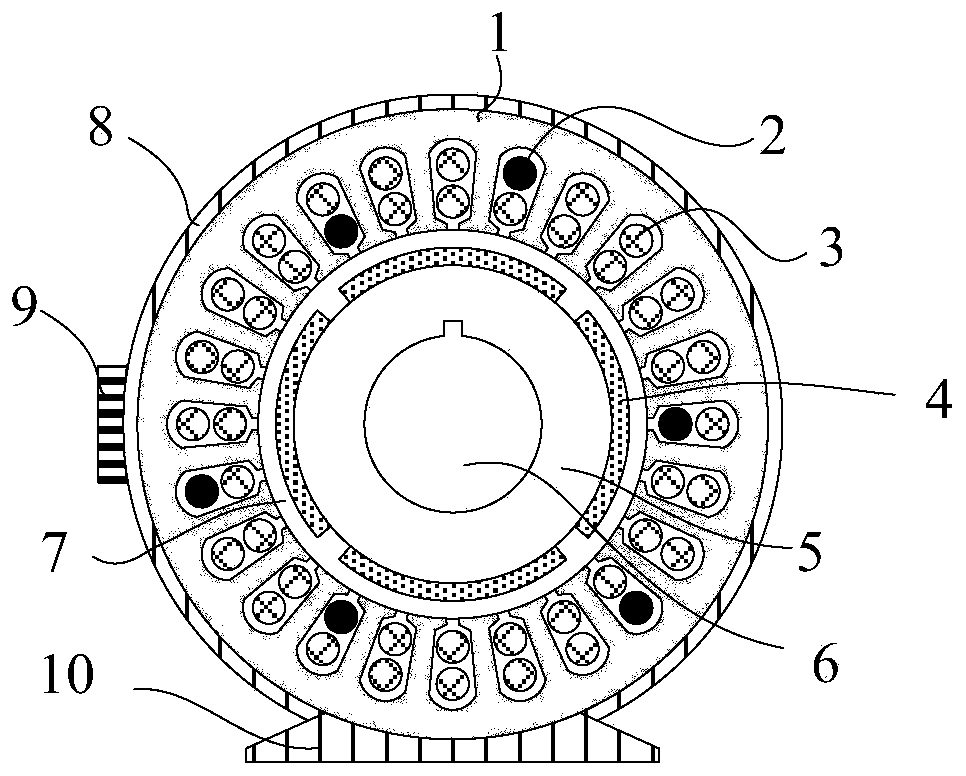

[0040] by figure 1 Take the surface-mounted permanent magnet motor as an example, the motor parameters are: phase number m=3, pole number 2p=4, slot number Q=24, pitch τ=5. Its structure includes: stator core 1, fault detection winding 2, main armature winding 3, permanent magnet pole 4, rotor core 5, rotating shaft 6, air gap 7, casing 8, junction box 9, base 10.

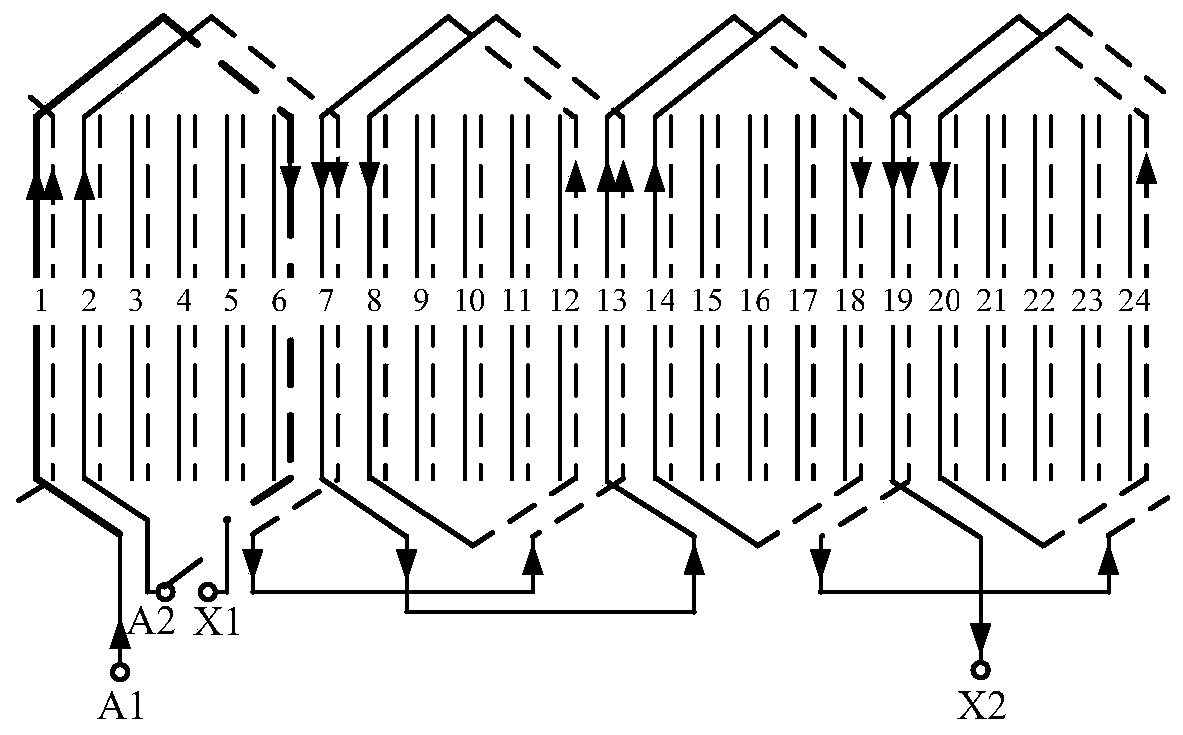

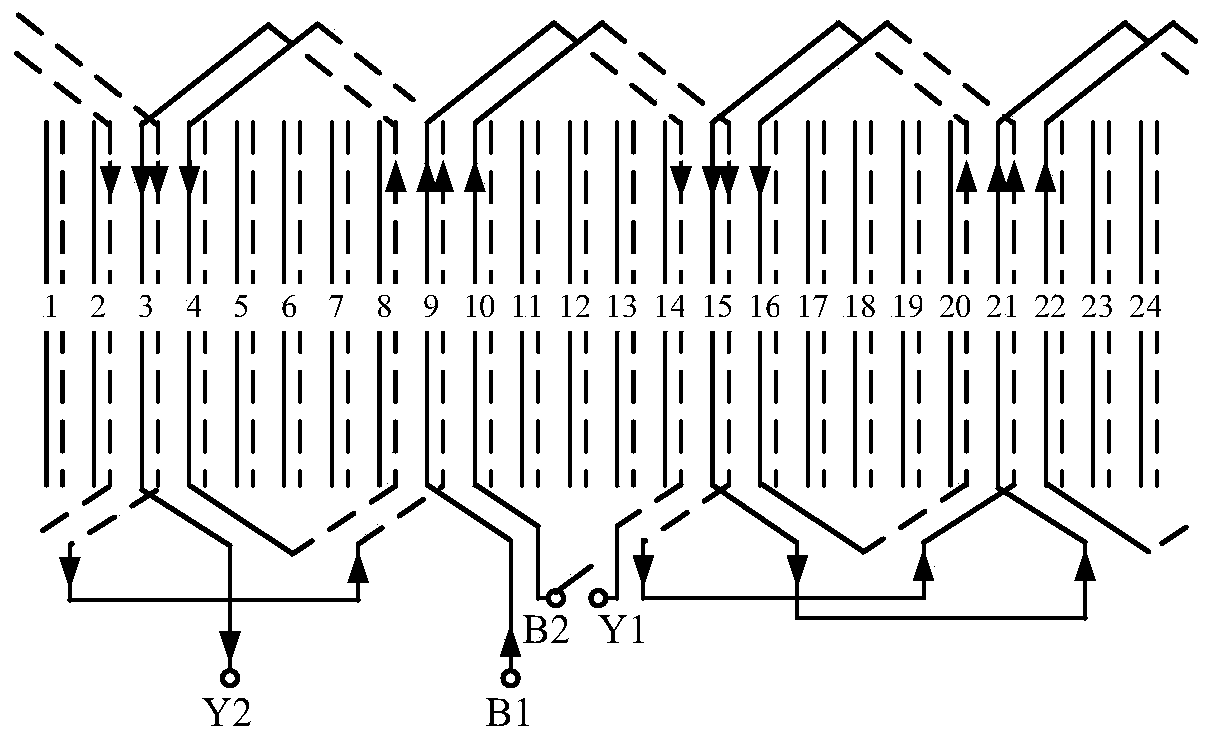

[0041] According to the number of poles of the motor 2p = 4, the number of slots Q = 24 and the pitch τ = 5, the slot number allocation table of the upper side of the three-phase winding can be calculated, as shown in Table 1.

[0042] Table 1 is the slot number allocation table of the upper side of the three-phase winding in the first embodiment

[0043] A Z B X C Y 1st pair of poles 1、2 23、24 9、10 7、8 17、18 15、16 2nd pole 13、14 11、12 21、22 19、20 5、6 3、4

[0044] Among them, the coil under the A-phase belt and the coil under the X-phase belt are recorded as the A-phase w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com