Ignition circuit and gas water heater

An ignition circuit and switching circuit technology, applied in circuits, electrical components, fluid heaters, etc., can solve problems affecting user experience, large discharge noise, etc., and achieve the effects of improving user experience, reducing ignition noise, and increasing on-off frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

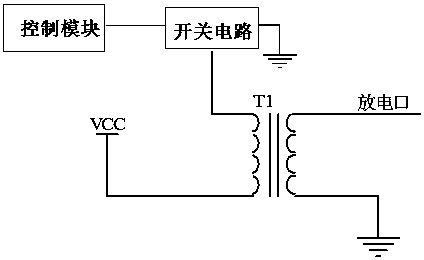

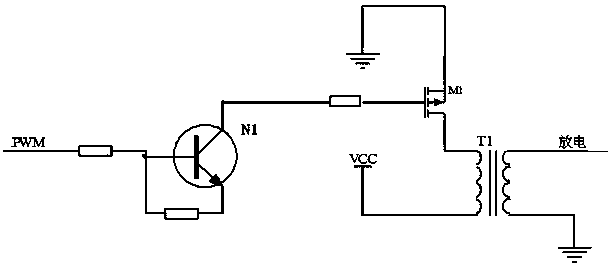

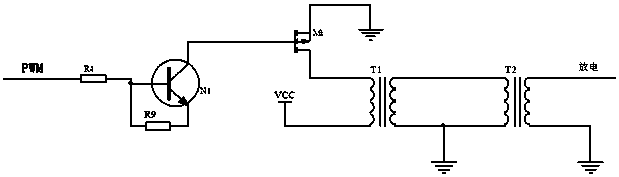

[0022] Embodiment 1, this embodiment proposes an ignition circuit, such as figure 1 As shown, it includes a control module, a switch circuit and at least one transformer. The control signal output terminal of the control module is connected to the control terminal of the switch circuit. The control module outputs a control signal to the switch circuit to control the conduction state of the switch circuit. The switch circuit is connected to Between the primary winding of the transformer and the power supply. In the ignition circuit of this embodiment, the switch circuit is used to control the conduction state of the primary winding of the transformer and the DC power supply. In the conduction state, the secondary winding of the transformer outputs a high-voltage signal according to the above frequency to discharge and ignite. The control module can increase the on-off frequency of the switching circuit to increase the ignition frequency. The total discharge energy remains uncha...

Embodiment 2

[0031] Embodiment 2. Based on the ignition circuit in Embodiment 1, this embodiment proposes a gas water heater, which includes a fan and the ignition circuit described in Embodiment 1. The fan is connected to a control module. For the specific composition of the ignition circuit, please refer to Embodiment 1 and the attached figure 1 , 2 recorded, and will not be repeated here. It should be noted that after the control module detects that the fan is started, it can output a control command to the ignition circuit for ignition to ensure safe use.

[0032]The gas water heater also includes a water flow detection module arranged in the water inlet pipe or the water outlet pipe, and the water flow detection module is connected with the control module. When it is detected that the water flow exceeds the starting threshold, the control module controls the fan to start, and then outputs a control command to the ignition circuit for ignition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com