A method and device for realizing powder compaction by radial and axial electromagnetic forces

An electromagnetic force and axial technology, applied in the field of powder compaction, to achieve the effects of reducing discharge energy, increasing compaction density, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

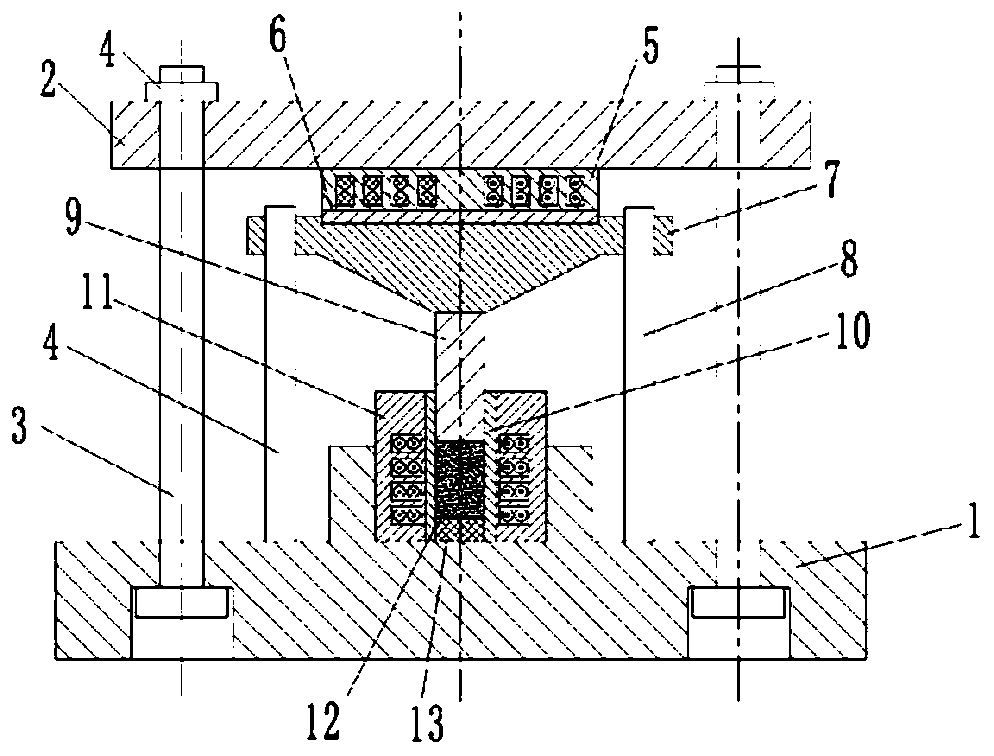

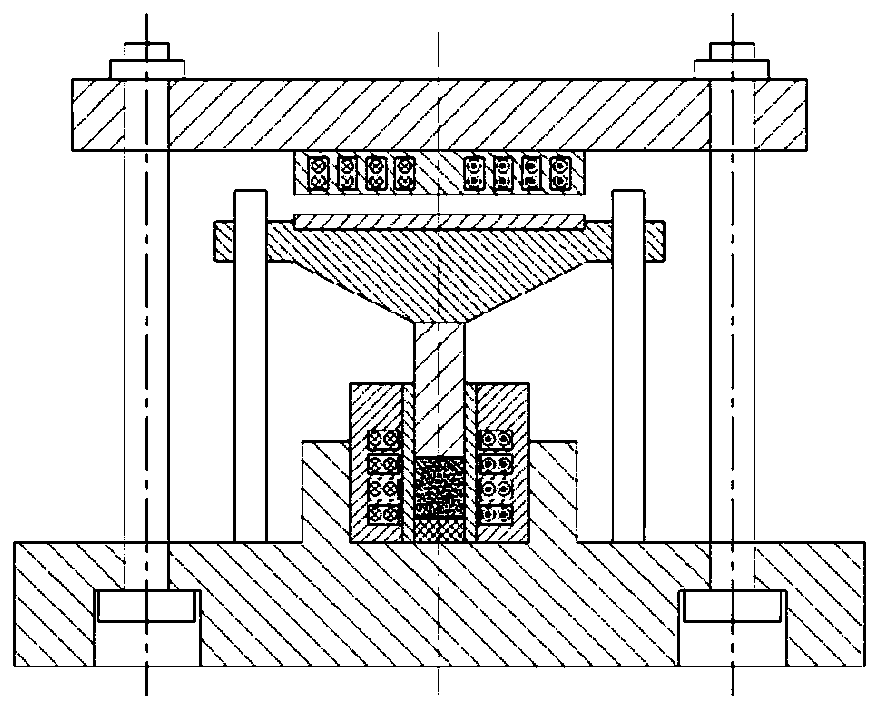

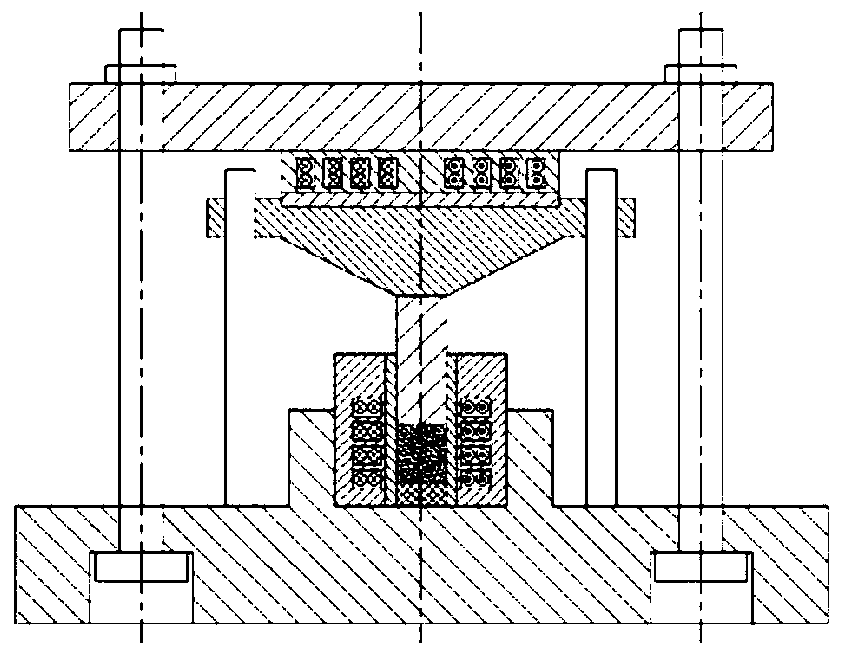

[0032] Such as figure 1 As shown, the present invention is a device for realizing powder compaction by radial and axial electromagnetic forces, including a base 1 and an upper fixing plate 2 , and the upper fixing plate 2 is connected to the base 1 by bolts 3 and nuts 4 . There is a sleeve 10 on the base 1, the bottom of the sleeve 10 is provided with a spacer 13, and the outer layer of the sleeve 10 is provided with a solenoid coil 11, and the solenoid coil 11 applies diameter to the powder 12 in the sleeve 10. to the electromagnetic force.

[0033] The top of the sleeve 10 is provided with a flat coil 5, the flat coil 5 is fixed on the lower surface of the upper fixing plate 2, and the solenoid coil 11 is snapped into the groove of the base 1, so as to ensure that the solenoid coil 11 will not move in the radial direction. Movement occurs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com