Multi-layer adhesive tape

A multi-layer bonding and adhesive tape technology, applied in the direction of adhesive type, ester copolymer adhesive, lamination, etc., can solve the problem of difficult physical properties of the adhesive tape, so as to promote the preparation cost and reduce the , the effect of high step coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0070] Hereinafter, the present invention will be described in detail with reference to Examples for specifically describing the present invention. However, the embodiments according to the present invention can be modified in various forms, and it should not be construed that the scope of the present invention is limited to the embodiments to be described below. The embodiments of this specification are provided to more fully explain the present invention to those skilled in the art.

[0071] [Preparation of Intermediate Adhesive Composition]

[0072] An intermediate bond comprising 75 parts by weight 2-methylhexyl acrylate, 10 parts by weight isobornyl methacrylate, 10 parts by weight acrylic acid, 5 parts by weight 2-hydroxyethyl acrylate and 5 parts by weight dimethylacrylamide was prepared agent composition.

[0073] [Preparation of outer adhesive composition]

[0074] An exterior adhesive composition comprising 88 parts by weight of 2-ethylhexyl acrylate, 10 parts by ...

Embodiment

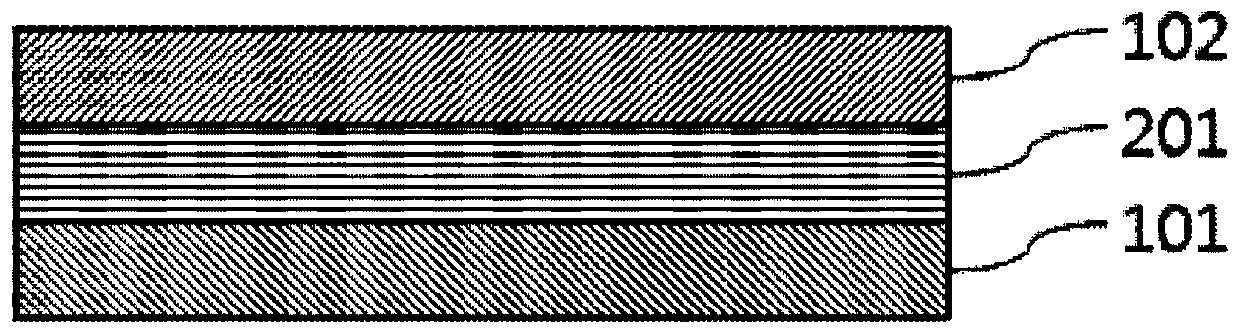

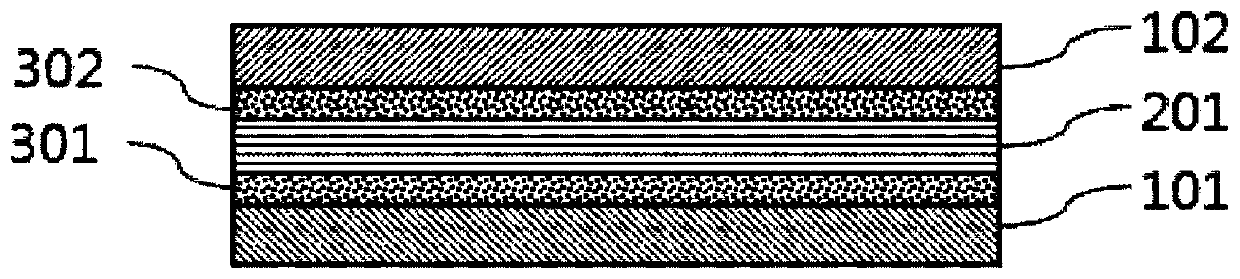

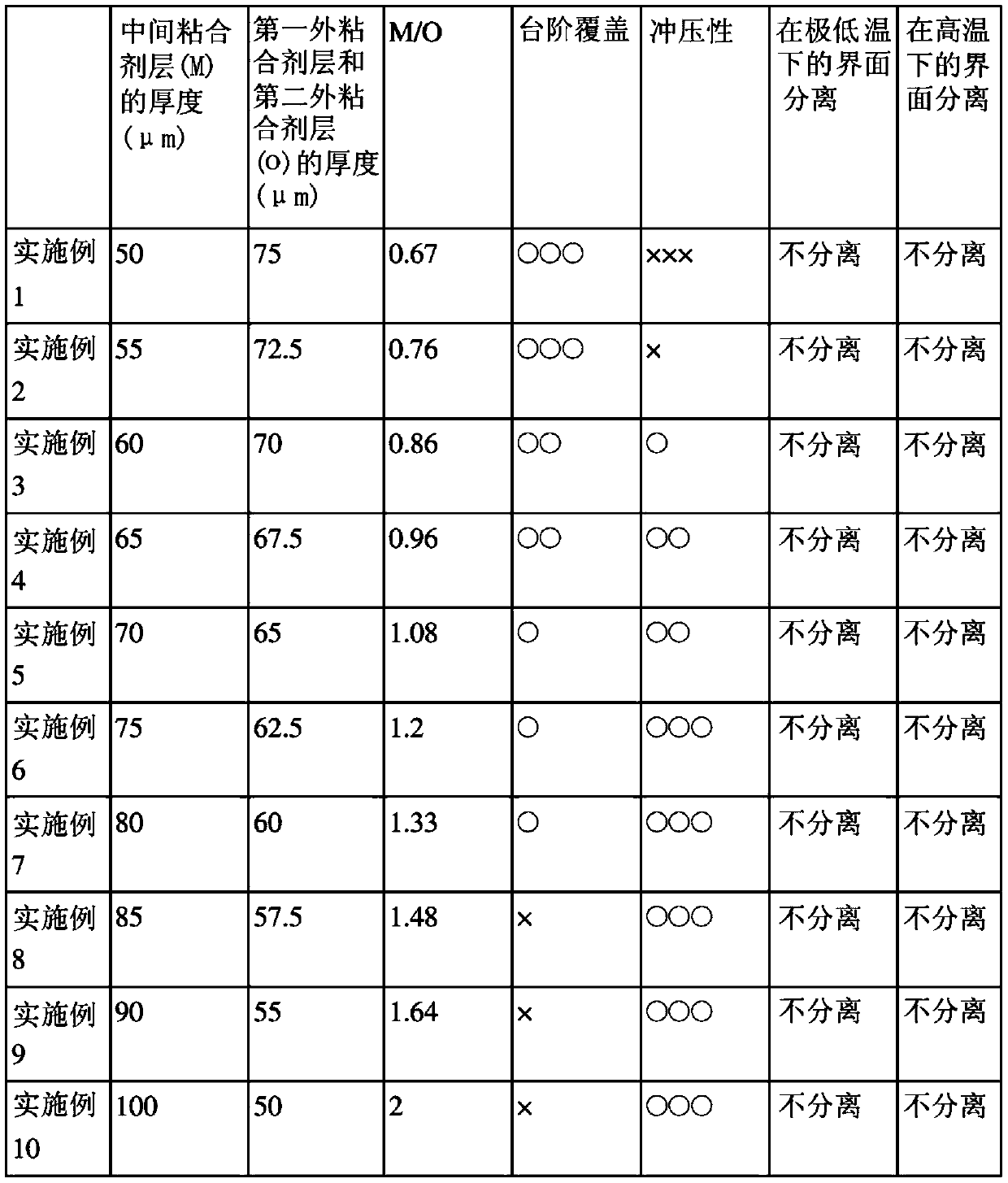

[0076] The prepared intermediate adhesive composition and the prepared outer adhesive composition are simultaneously coated to laminate the outer adhesive composition, the intermediate adhesive composition, and the outer adhesive composition, and then by using a black light, The composition was UV cured to prepare a multilayer adhesive tape sequentially comprising a first outer adhesive layer, a middle adhesive layer, and a second outer adhesive layer. The thicknesses of the layers of the multilayer adhesive tapes prepared according to the Examples are shown in Table 1 below.

[0077] In addition, with respect to each of the multilayer adhesive tapes prepared by the examples, step coverage, punchability, presence or absence of interfacial separation phenomenon at extremely low temperature, presence or absence of interfacial separation phenomenon at high temperature, etc. are shown in Table 1 below.

[0078] [Table 1]

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com