Protection device based on sandblast spray coating of casing installation edge spigots

A protection device and stopper technology, applied in the direction of injection device, used abrasive treatment device, abrasive, etc., can solve the problem of affecting the normal use of the non-sprayed surface of the casing, unable to improve the spraying processing efficiency, and inconvenient to load and unload the casing, etc. problems, to avoid manual clamping, compact structure, and full protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

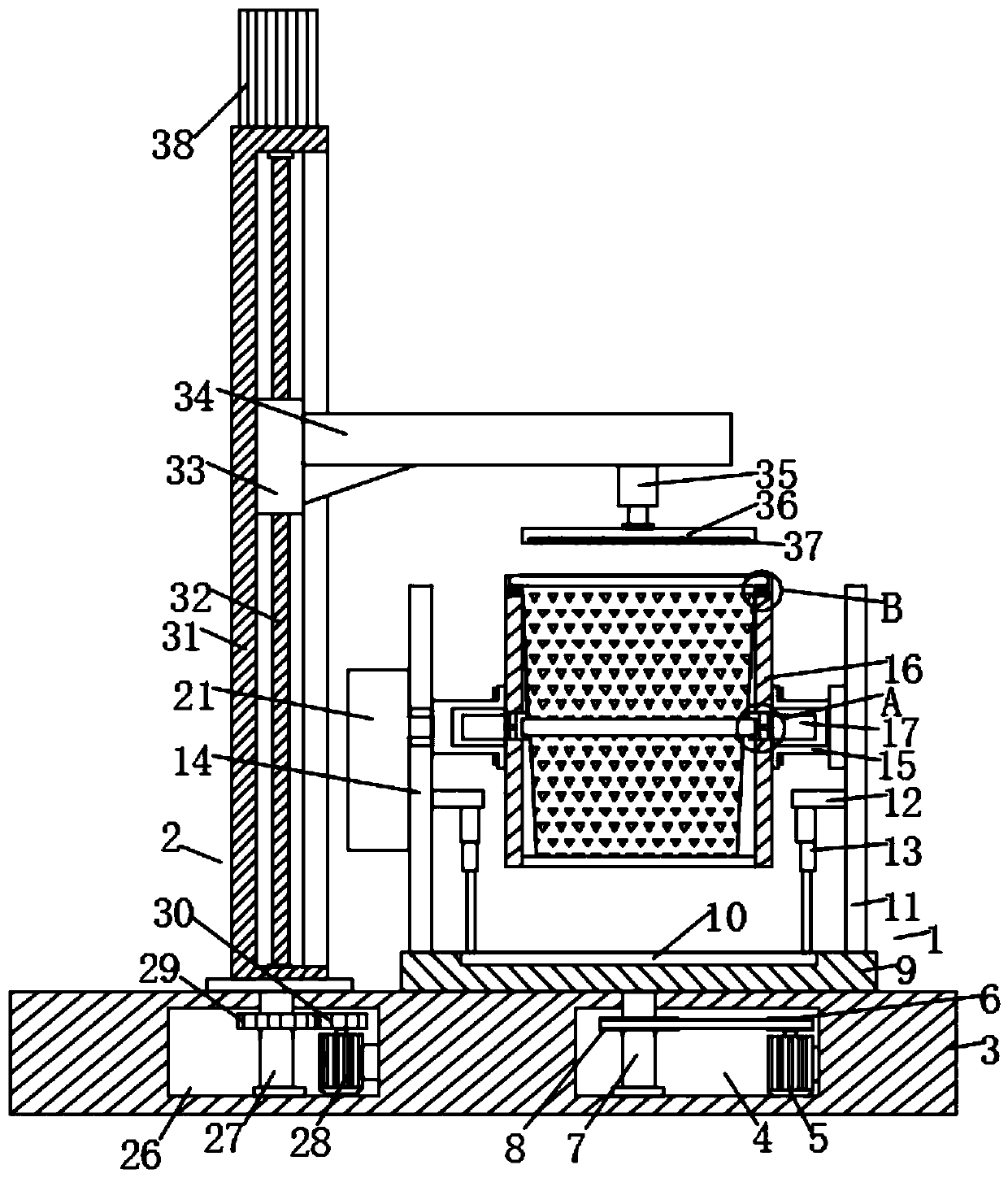

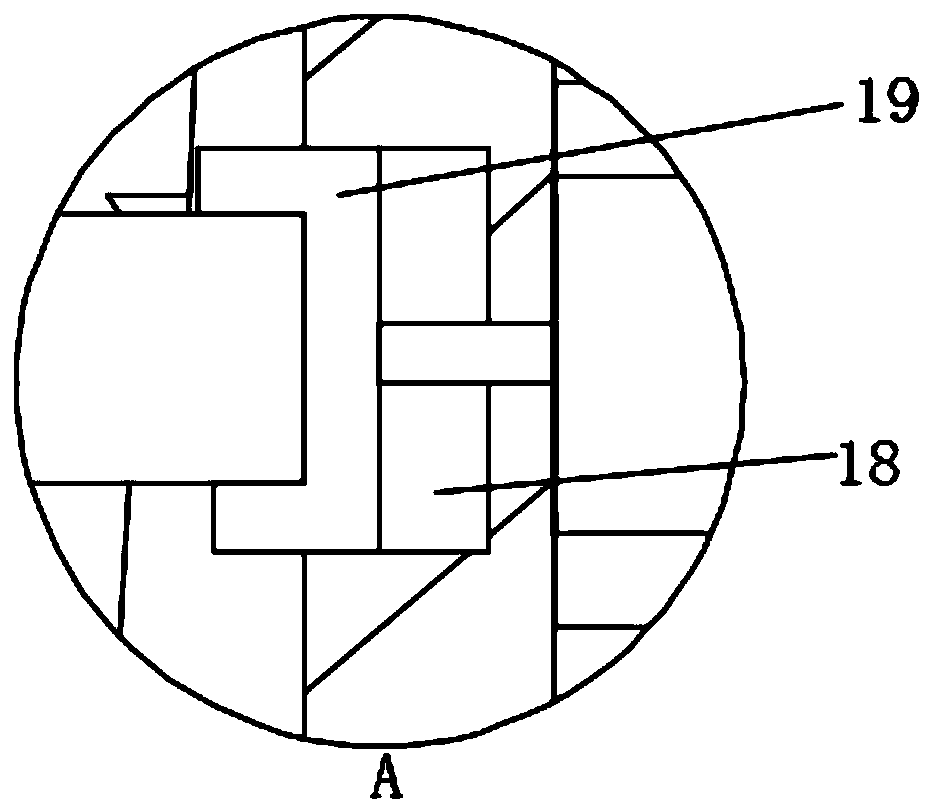

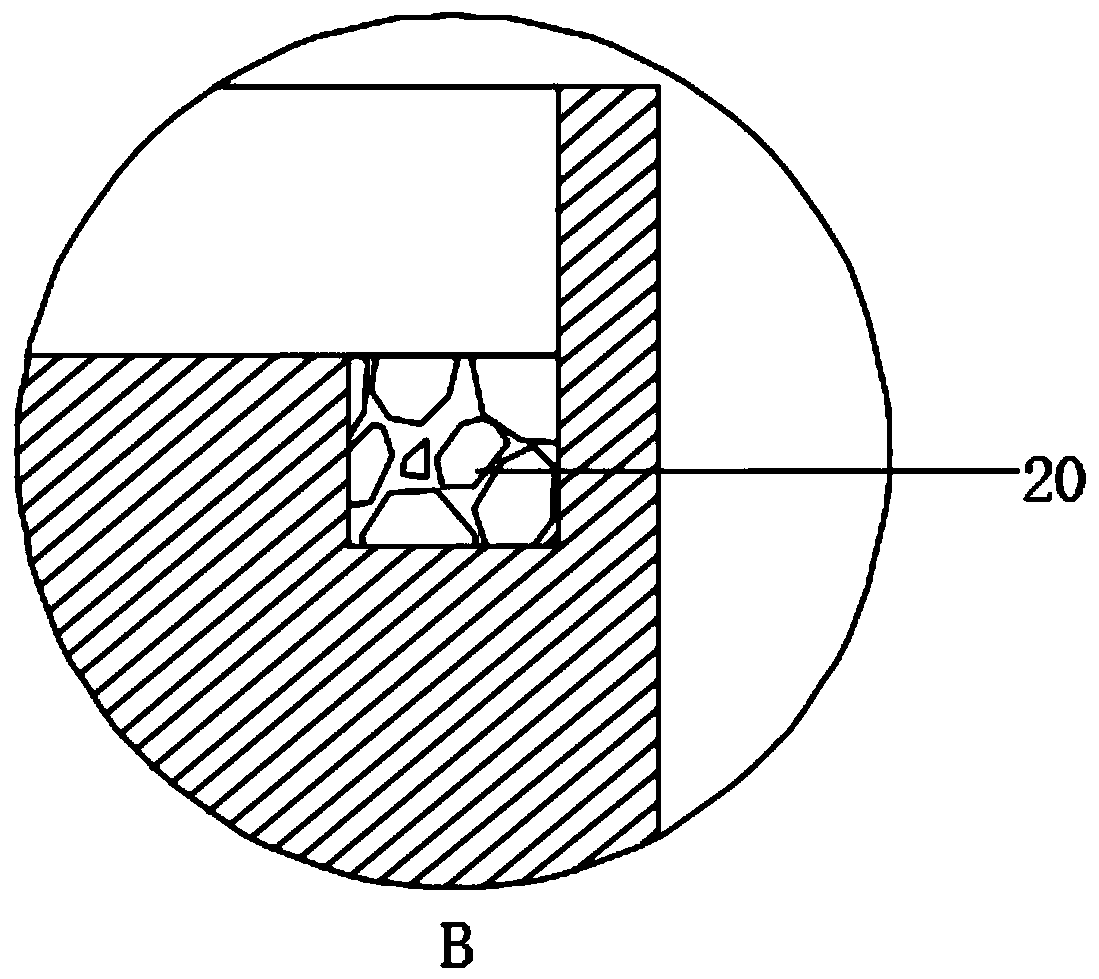

[0022] Example: such as Figure 1-5 As shown, the present invention is based on a protective device for sand blowing and spraying on the side of the casing, including a protective mechanism 1 and a loading and unloading mechanism 2. The protective mechanism 1 is composed of a fixed base 3, a first rotating chamber 4, and a rotating motor 5. , the first pulley 6, the first rotating shaft 7, the second pulley 8, the rotating plate 9, the bottom baffle 10, the first support column 11, the fixed mounting seat 12, the electric telescopic rod 13, the second support column 14, the fixed card Groove 15, protective barrel 16, clamping cylinder 17, reset card slot 18, fixed clamping plate 19, first electromagnet 20, transmission box 21, conversion motor 22, transmission worm 23, transmission worm wheel 24 and conversion shaft 25 are formed, all One end inside the fixed base 3 is dug with a first rotating cavity 4, and one end inside the first rotating cavity 4 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com