Combined calibration method between three-dimensional laser radar and mechanical arm of mobile operation robot

A 3D laser and mobile operation technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of not being able to meet the 3D environment perception of mobile operation robots, the inability of 2D lasers to complete 3D environment perception, and the impact of calibration results, so as to reduce dependence and improve The effect of calibration accuracy and simple calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

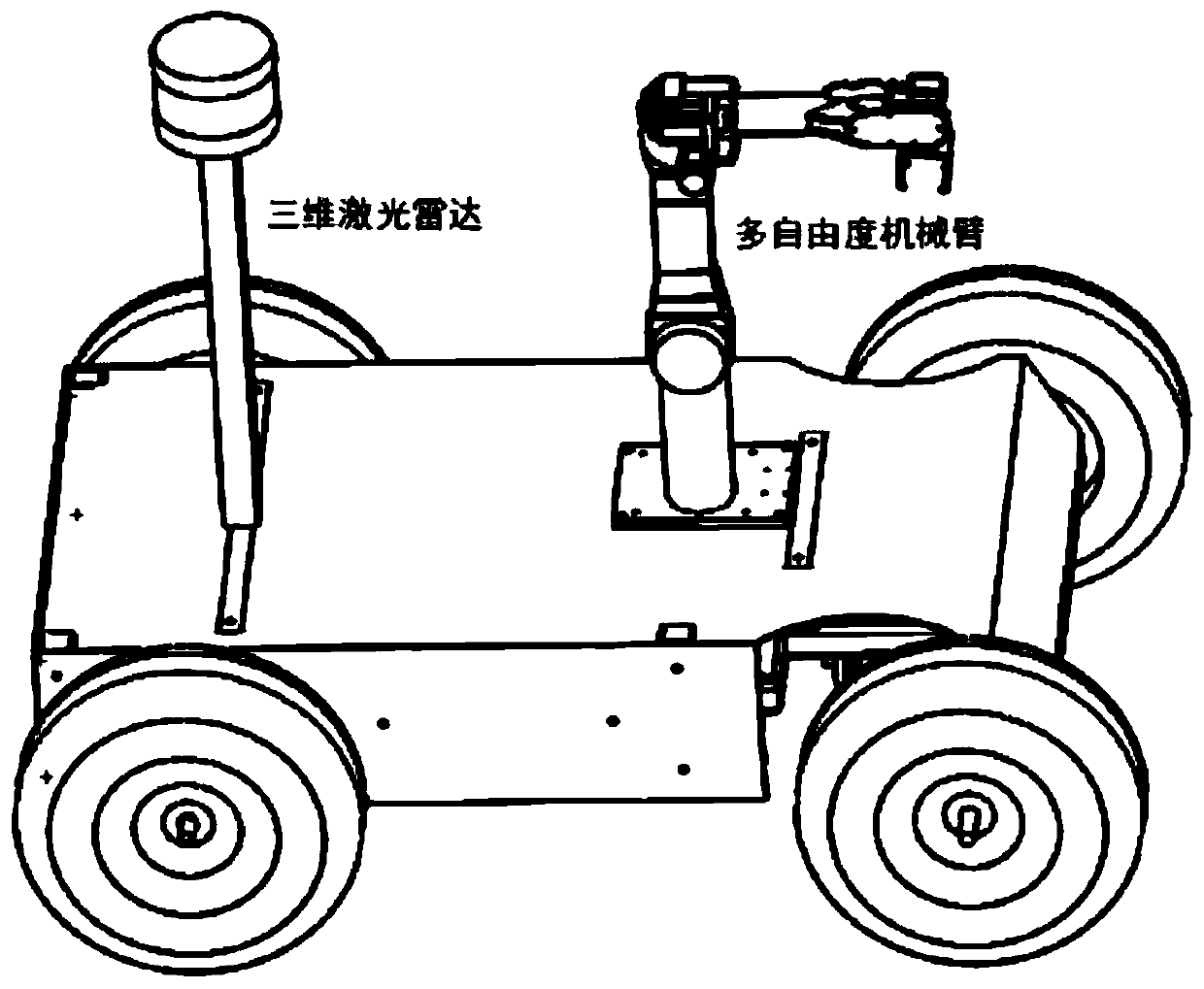

[0050] The three-dimensional laser radar used in the specific implementation process of the present invention is the 16-line laser VLP-16 of Velodyne Company, the mechanical arm is a 6-DOF robotic arm SRQ05A-6D and its corresponding controller, and the square cardboard held by the end of the mechanical arm is a square Cardboard with a side length of 10 cm. The method proposed in the present invention is also suitable for 32-, 64-line or other specifications of three-dimensional laser radar, as well as mechanical arms with other degrees of freedom.

[0051] Take the text’s invention of 3D laser radar and robotic arm as an example, especially the 16-line 3D laser and 6-axis robotic arm. The horizontal scanning angle of the 3D laser is 360 degrees, the vertical scanning angle is ±15 degrees, the scanning frequency is 10Hz, and about 300,000 point cloud data are collected per second; the 6-axis robotic arm has 6 degrees of freedom, the payload is 5kg, and the joints run The speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com