A shock pressure test system

A test system and impact pressure technology, which is applied in fluid pressure actuation system components, fluid pressure actuation system testing, fluid pressure actuation devices, etc. The boosting speed cannot meet the product test requirements, etc., to achieve the effect of increasing the upper pressure limit, boosting speed, and increasing the alternating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

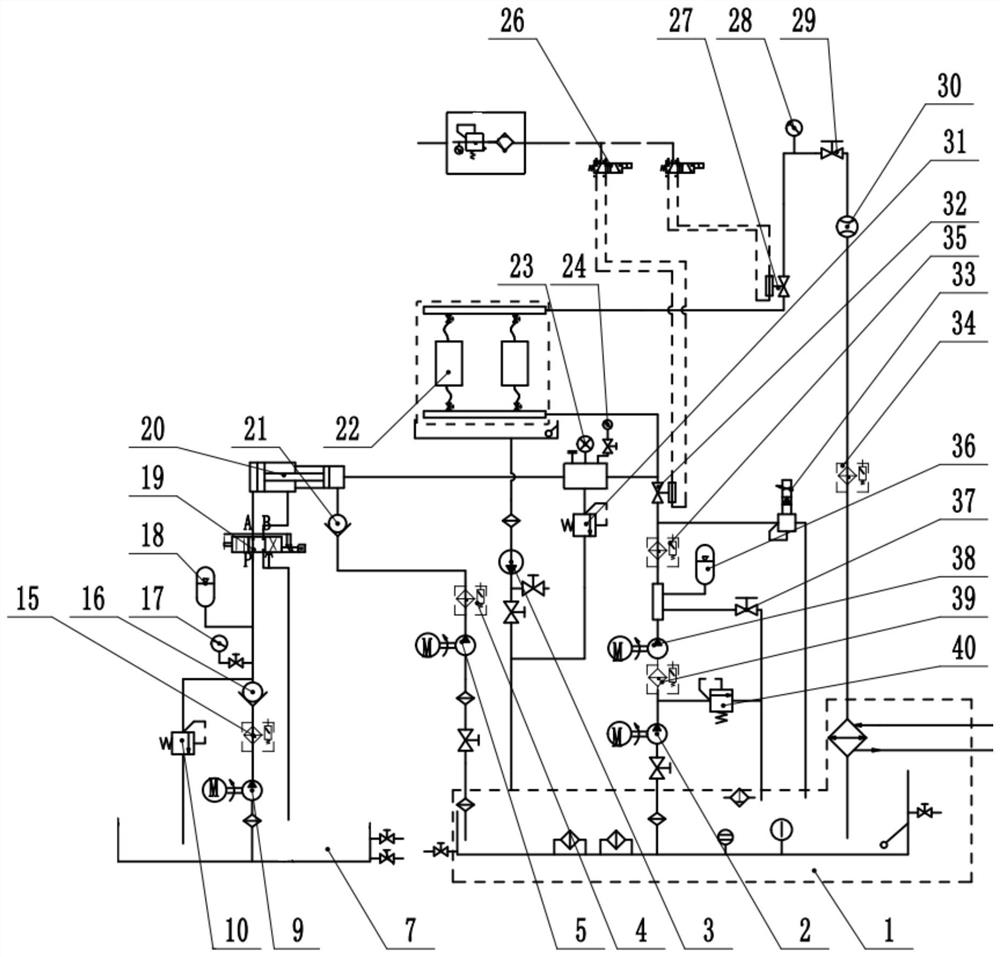

[0032] Referring to the accompanying drawings, an impact pressure test system includes a high-pressure open control subsystem and a servo control subsystem.

[0033] The high-pressure open control subsystem includes the first fuel tank 1, the liquid replenishment pump group I2, the high-pressure pump 38, the accumulator I36, the electromagnetic proportional overflow valve I33, the air-operated ball valve I32, and the air-operated ball valve II27.

[0034] The inlet of the replenishment pump group I2 is connected to the first oil tank 1, the outlet of the replenishment pump group I2 is connected to the inlet of the high pressure pump 38 through the pipeline, the outlet of the high pressure pump 38 is connected to the inlet of the air control ball valve I32 through the pipeline, and the outlet of the air control ball valve I32 is connected to the The inlet of the piece to be tested 22, the outlet of the piece to be tested 22 are connected to the inlet of the air control ball valv...

Embodiment 2

[0049] On the basis of Embodiment 1, further, a waste liquid receiving tank is arranged on the periphery of the test piece, and the oil return port at the bottom of the waste liquid receiving tank is connected back to the first oil tank 1 through a pipeline, and a pump 3 and a pump 3 are arranged on the pipeline. valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com