Novel air valve applicable to liquid supplement

A technology of air and valves, applied in the direction of diaphragm valves, valve devices, engine components, etc., can solve problems such as adverse effects of downstream equipment, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

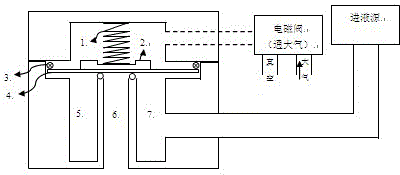

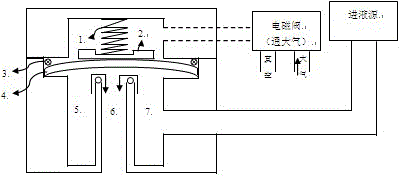

[0009] combined with figure 1 And attached figure 2 The technical solution provided by the present invention is described in further detail.

[0010] When the solenoid valve is open to the atmosphere, as attached figure 1 As shown, the sealed space inside the metal upper cover is at normal atmospheric pressure. At this time, the moderately compressed spring exerts a downward pressure on the metal gasket, and the metal gasket tightly presses the plastic sheet, so that the plastic sheet and the sealing ring under the sheet Close fit, the liquid in the liquid storage tank cannot flow into the liquid supply pipe, at this time, this product has the function of stopping the liquid supply.

[0011] When the solenoid valve passes a certain amount of vacuum, if the attached figure 2 As shown, the metal upper cover has an appropriate amount of negative pressure in the sealed space, which produces an upward pulling force on the plastic sheet. By properly adjusting the vacuum negativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com