A self-cleaning solar collector tube

A solar collector tube and self-cleaning technology, which is applied in the field of solar energy, can solve the problems that solar collector tubes are easy to adhere to dust and affect the efficiency of solar energy conversion heat energy of the collector tube, so as to improve conversion efficiency, increase utilization rate, and improve heat absorption efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

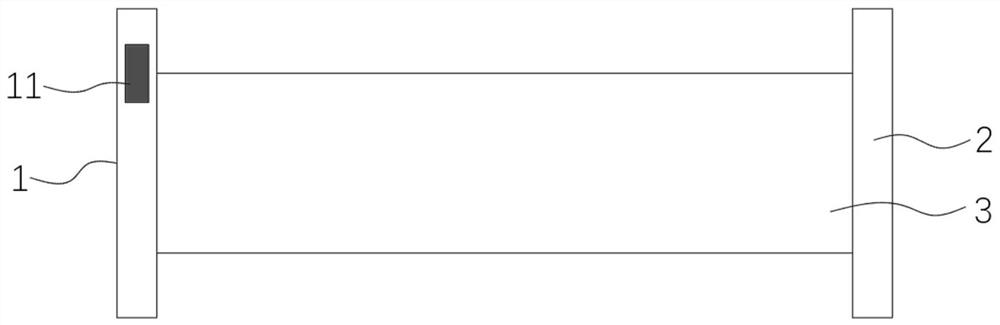

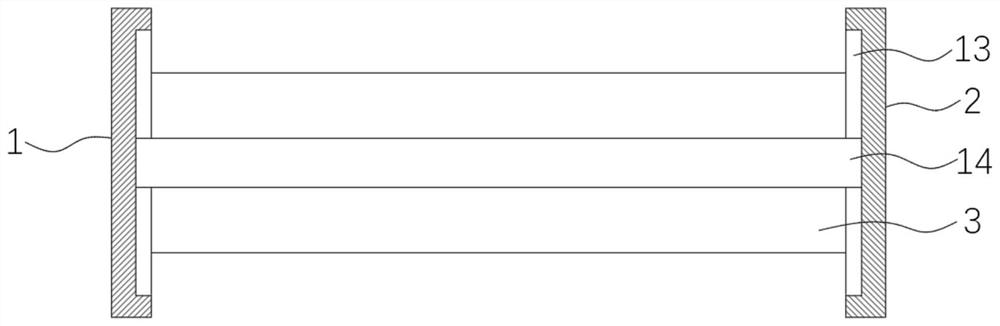

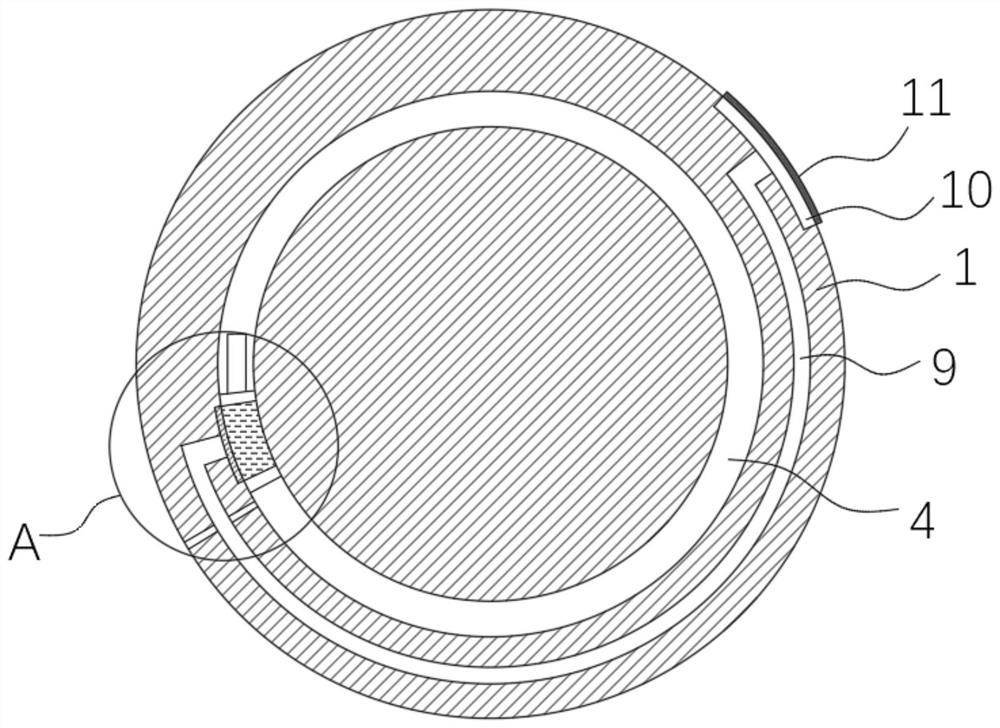

[0020] refer to Figure 1-6 , a self-cleaning solar heat collection tube, including a left support plate 1 and a right support plate 2 arranged in parallel, the left support plate 1 and the right support plate 2 both adopt a circular structure, and the left support plate 1 and the right support plate 2 are close to each other The side wall of one side of the heat collecting pipe 3 is installed together, and the specific structure of the heat collecting pipe 3 and its working mode are all mature prior art, so it will not be repeated here, and the left support plate 1 is provided with an annular cavity 4, and the annular cavity 4 The inner wall is fixedly connected with a fixed arc plate 5, the inner wall of the annular cavity 4 is sealed and slidably connected with an arc-shaped sliding plug 6, and the upper end surface of the arc-shaped sliding plug 6 is fixedly connected with an inner magnet 7, which is located between the fixed arc plate 5 and the arc-shaped sliding plug 6 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com