Conductive backboard with high heat dissipation and low resistivity and manufacturing method thereof

A low-resistivity, conductive backplane technology, applied in the field of solar cells, to achieve the effect of improving outdoor weather resistance, prolonging service life, and improving use stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

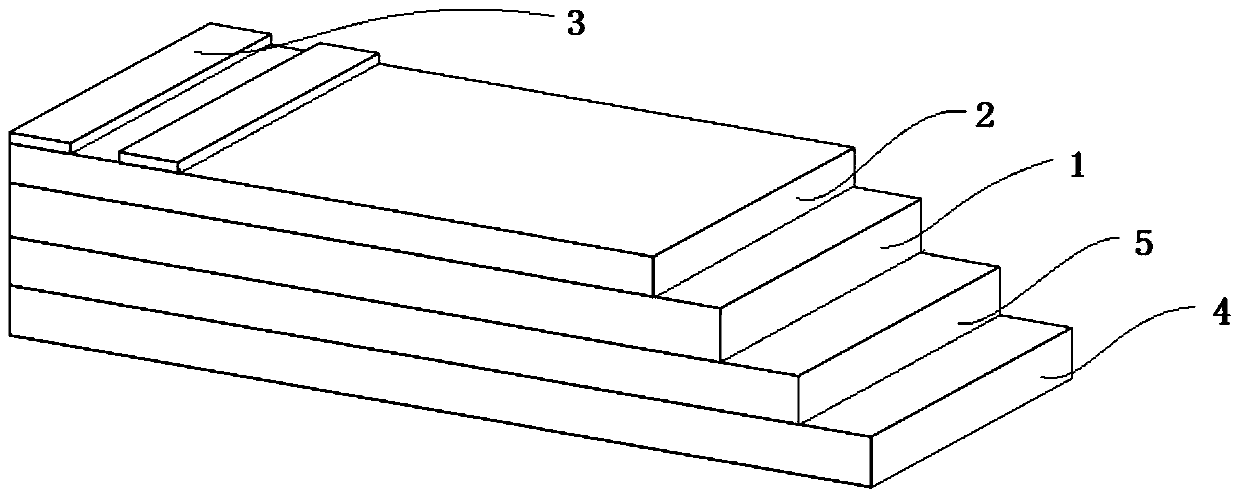

[0033] A conductive backplane with high heat dissipation and low resistivity and its manufacturing method, comprising: a carrier substrate layer 1, a thermally conductive adhesive layer 2, a metal layer 3, a weather-resistant layer 4, and a weather-resistant adhesive layer 5;

[0034] Concrete preparation process is as follows:

[0035] step 1

[0036] Preferably, the metal layer 3 is copper foil with a thickness of 10 μm.

[0037] The carrier substrate layer 1 is preferably modified polyethylene terephthalate (PET), which is rectangular and has a thickness of 20 μm. The raw material of the thermally conductive adhesive layer 2 is evenly coated on its upper surface, which includes: polyurethane adhesive agent, modified phenolic resin, and 2% aluminum oxide by mass percentage, and form a thermally conductive adhesive layer 2 with a thickness of 5 μm, and then attach the lower surface of the metal layer 3 (copper foil) to the thermally conductive adhesive layer 2, on the upper ...

Embodiment 2

[0045] A conductive backplane with high heat dissipation and low resistivity and its manufacturing method, comprising: a carrier substrate layer 1, a thermally conductive adhesive layer 2, a metal layer 3, a weather-resistant layer 4, and a weather-resistant adhesive layer 5;

[0046] Concrete preparation process is as follows:

[0047] step 1

[0048] Preferably, the metal layer 3 is copper foil with a thickness of 50 μm.

[0049]The carrier substrate layer 1 is preferably modified polyethylene terephthalate (PET), which is rectangular and has a thickness of 250 μm. The raw material of the thermally conductive adhesive layer 2 is evenly coated on its upper surface, which includes: two-component polyurethane Adhesive, modified phenolic resin, and 30% aluminum oxide by mass percentage, and form a thermally conductive adhesive layer 2 with a thickness of 30 μm, and then attach the lower surface of the metal layer 3 (copper foil) to the thermally conductive adhesive layer 2, Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com