Preparation method of Vb group metal ion doped (ga1-xznx) (n1-xox) solid solution photocatalyst

A metal ion and photocatalyst technology, which is applied in the field of preparation of VB group metal ion doped solid solution photocatalyst, can solve the problems of low oxygen production performance and the like, and achieves the effects of simple operation, improved solar energy conversion efficiency and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

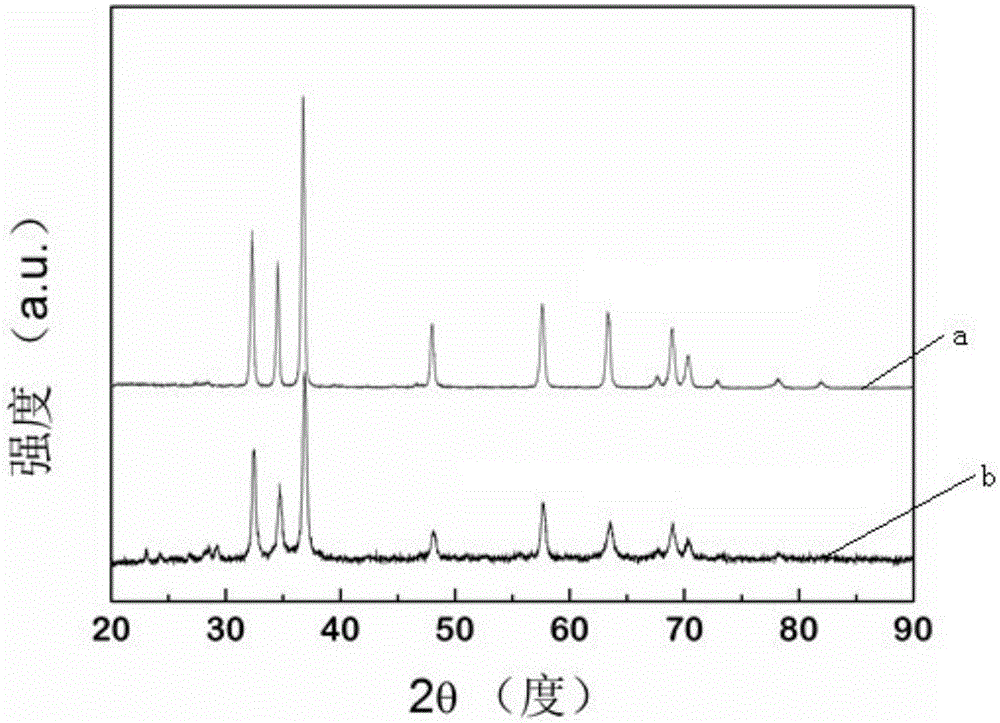

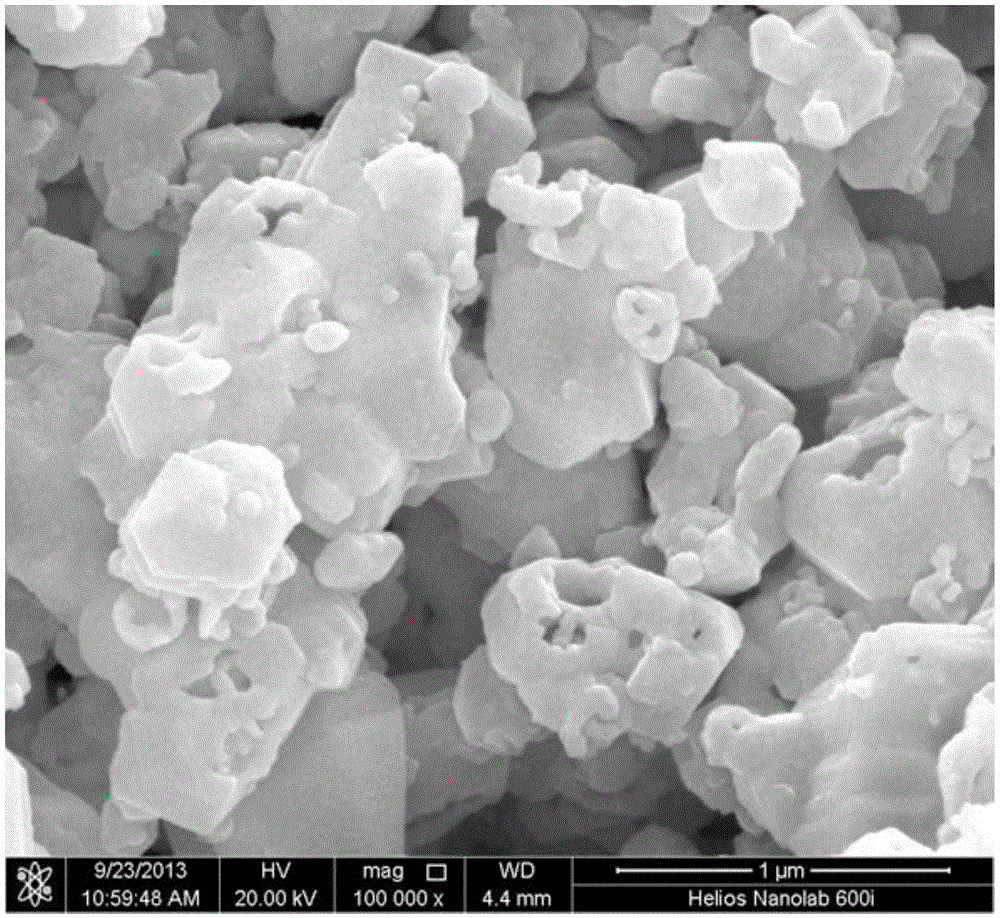

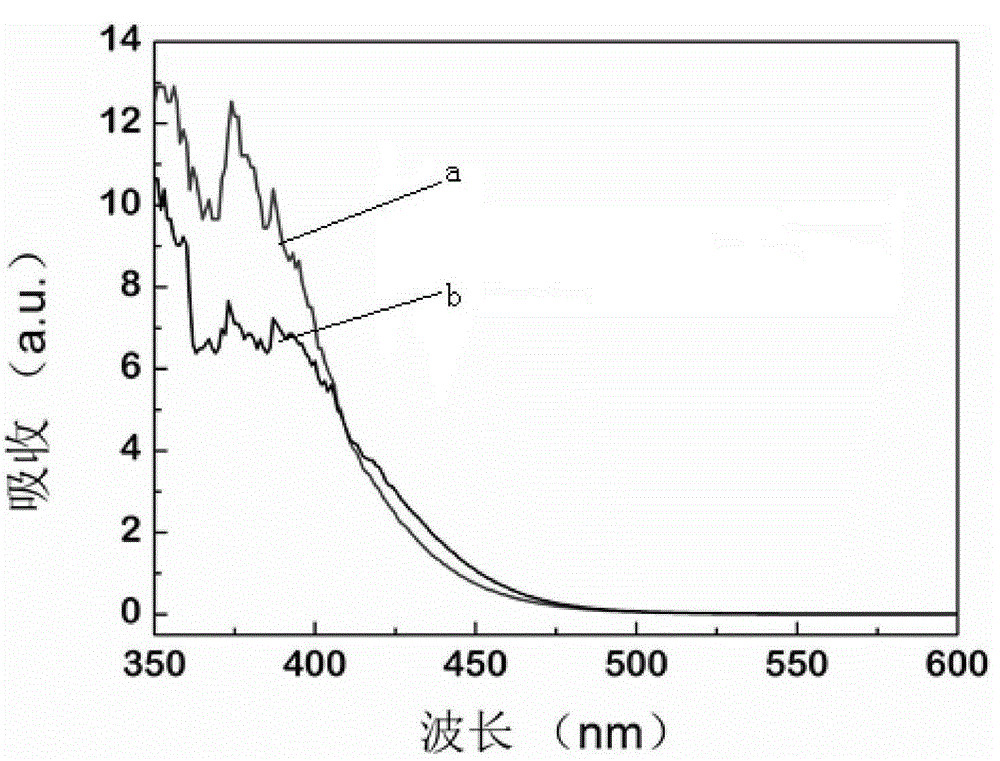

[0011] Specific implementation mode one: this implementation mode VB group metal ion doping (Ga 1-x Zn x )(N 1-x o x ) The preparation method of solid solution photocatalyst is to carry out in the following steps: one, Ga 2 o 3 Mix with ZnO, add VB group metal compound after mixing, and then place it in an agate mortar for grinding at room temperature to obtain a ground precursor; 2. Calcinate the ground precursor in an ammonia atmosphere, and then After cooling to 100°C under the atmosphere, take it out, then cool to room temperature, and then wash with deionized water and absolute ethanol to obtain VB group metal ion doping (Ga 1-x Zn x )(N 1-x o x ) solid solution photocatalyst, which is completed; where (Ga 1-x Zn x )(N 1-x o x ) in x is 02 o 3 And the molar ratio of Ga element to Zn element in ZnO is 1: (0.8-1.1), and the molar ratio of the sum of Ga element and Zn element to VB group metal element is 1: (0.01-0.1).

[0012] In this embodiment, Ga 2 o 3 , Z...

specific Embodiment approach 2

[0013] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the compound of Group VB metal in Step 1 is an oxide of Group VB metal or a nitrate of Group VB metal. Others are the same as the first embodiment.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the grinding time in step 1 is 30-60 minutes. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com