Preparation method of few-layer transition metal oxyhydroxide electro-catalysis electrode with step/crack structure

A technology of transition metal and oxide electrolysis, which is applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of complex preparation methods, high costs, and long processes, and achieve simple processes, low cost, and small contact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

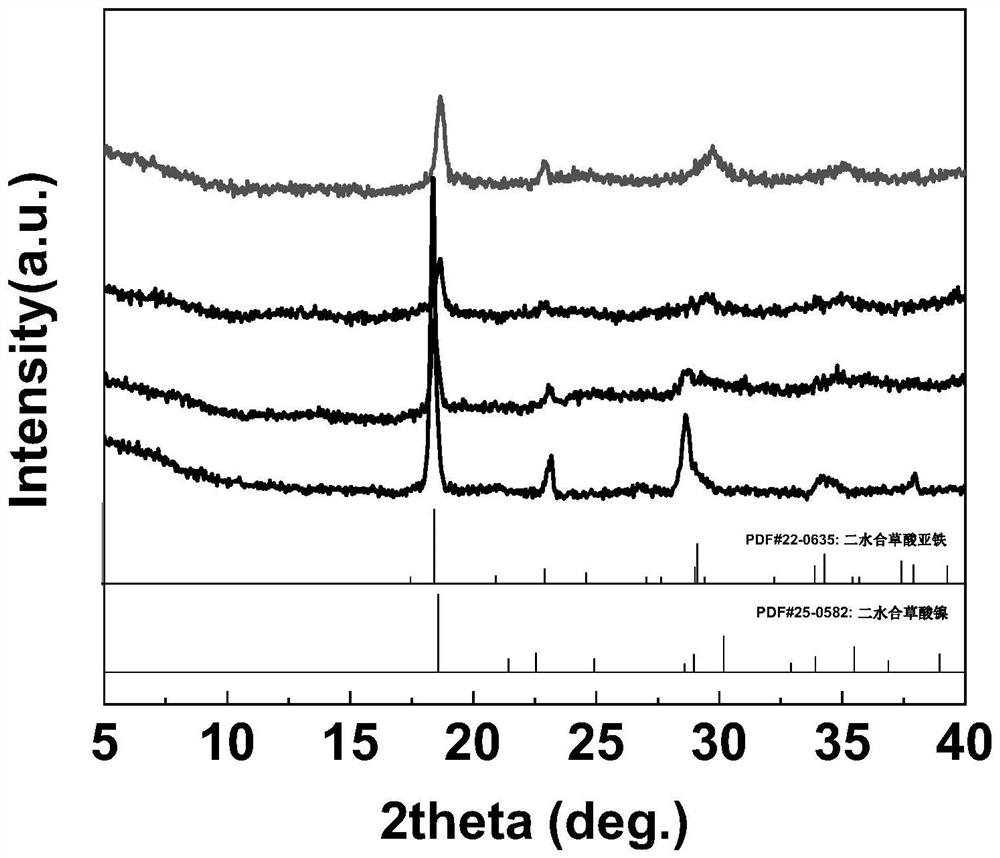

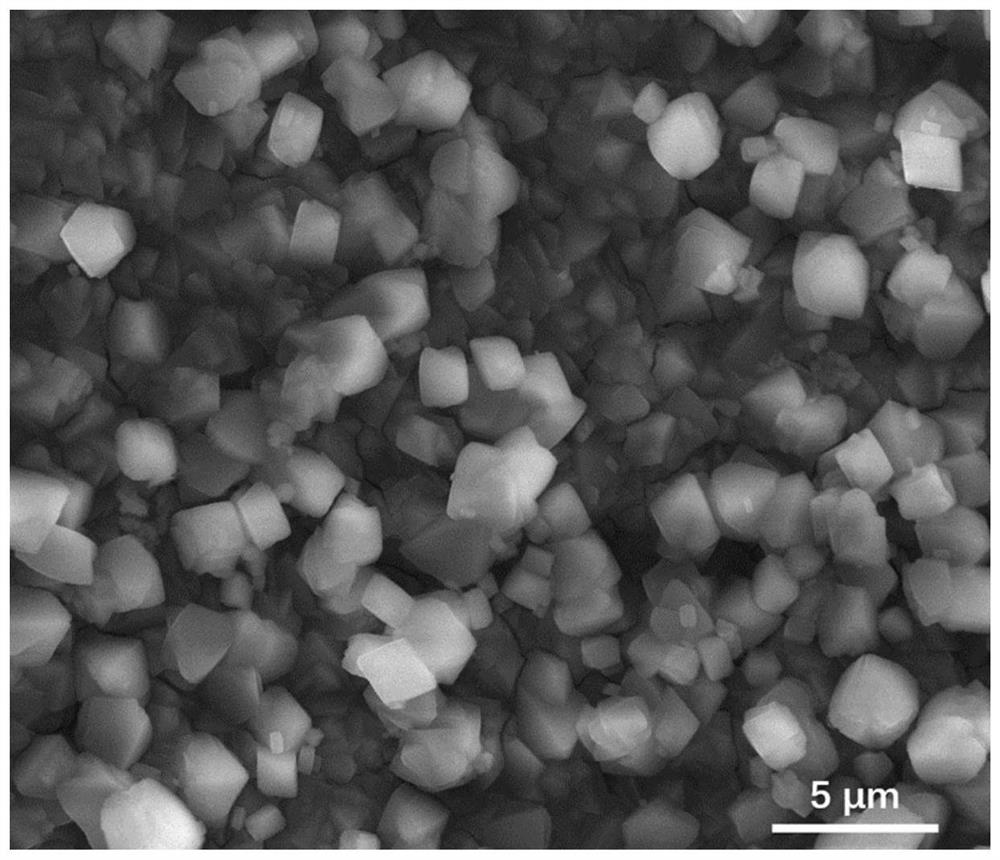

[0057] In this embodiment, the preparation of the Fe / Ni-based oxyhydroxide electrocatalyst of ultra-thin structure:

[0058] 1.11g ferrous sulfate heptahydrate and 2.1g nickel sulfate hexahydrate were dissolved in 50mL deionized water to configure mixed metal salt solution A, and 1.26g oxalic acid was dissolved in a mixed solution of 50mL absolute ethanol and deionized water (1 : 4), adjust the pH value to 5 with ammonia water, configure it as oxalic acid solution B, heat the oxalic acid solution B to the reaction temperature of 50 ° C, and ultrasonically clean the foamed nickel substrate (2 × 6cm 2 ) is fixed with clips, immersed in oxalic acid solution B, preheated for 5 to 10 minutes, poured in mixed metal salt solution A, reacted for 30 minutes, cooled naturally, taken out, rinsed and dried to obtain iron / nickel loaded with nickel foam Oxalate intermediate.

[0059] Electrochemical in situ conversion by cyclic voltammetry: using a three-electrode system, the iron / nickel o...

Embodiment 2

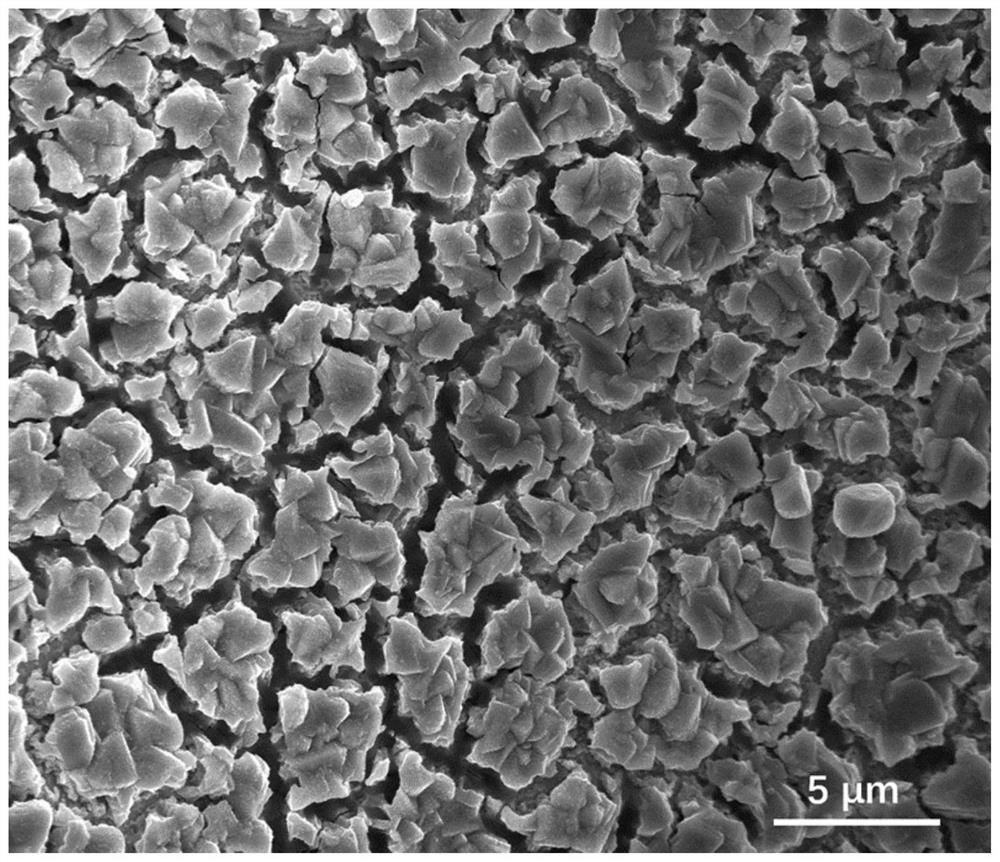

[0062] In this example, the preparation of the Co / Ni-based oxyhydroxide electrocatalyst electrode with ultra-thin structure:

[0063] Dissolve 1.4g of cobalt sulfate heptahydrate and 1.31g of nickel sulfate hexahydrate in 50mL of deionized water to configure mixed metal salt solution A. Dissolve 1.26g of oxalic acid in a mixed solution of 50mL of absolute ethanol and deionized water (1: 4), adjust the pH value to 6 with ammonia water, configure it as oxalic acid solution B, heat the oxalic acid solution B to the reaction temperature of 50 ° C, and ultrasonically clean the foamed nickel substrate (2 × 6cm 2 ) fixed with clips, immersed in oxalic acid solution B, preheated for 5 to 10 minutes, poured mixed metal salt solution A into oxalic acid solution B, reacted for 30 minutes, cooled naturally, took out the substrate, rinsed and dried, and obtained foam Nickel supported cobalt / nickel oxalate intermediate.

[0064] Electrochemical in situ conversion by cyclic voltammetry: usi...

Embodiment 3

[0067] In this example, the preparation of the Co / Fe-based oxyhydroxide electrocatalyst with ultra-thin structure:

[0068]1.4g cobalt sulfate heptahydrate and 1.36g ferrous sulfate heptahydrate were dissolved in 50mL deionized water to configure mixed metal salt solution A, and 1.26g oxalic acid was dissolved in a mixed solution of 50mL absolute ethanol and deionized water (1 : 4), adjust the pH value to 5 with ammonia water, configure it as oxalic acid solution B, heat the oxalic acid solution B to the reaction temperature of 50 ° C, and ultrasonically clean the foamed nickel substrate (2 × 6cm 2 ) is fixed with clips, immersed in oxalic acid solution B, preheated for 5 to 10 minutes, poured in mixed metal salt solution A, reacted for 30 minutes, cooled naturally, taken out, rinsed and dried to obtain foamed nickel-supported cobalt / iron Oxalate intermediate.

[0069] Electrochemical in situ conversion by cyclic voltammetry: using a three-electrode system, the cobalt / iron ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com