Multi-factor comprehensive plateau alpine climate environment simulation acceleration test device

A climate environment, accelerated test technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, and simultaneous control of multiple variables, etc., can solve the problem of inability to fully and accurately evaluate equipment adaptability and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

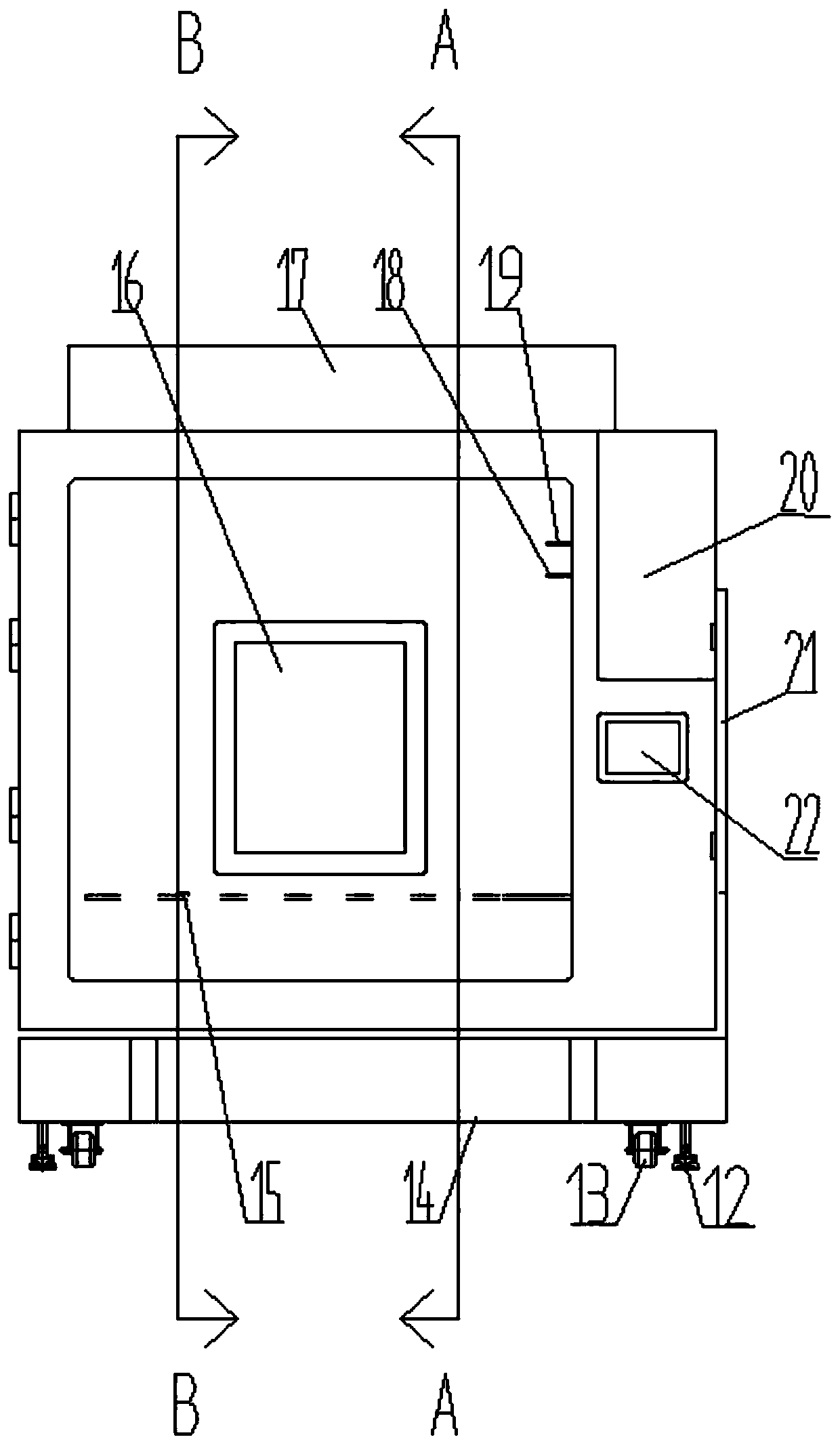

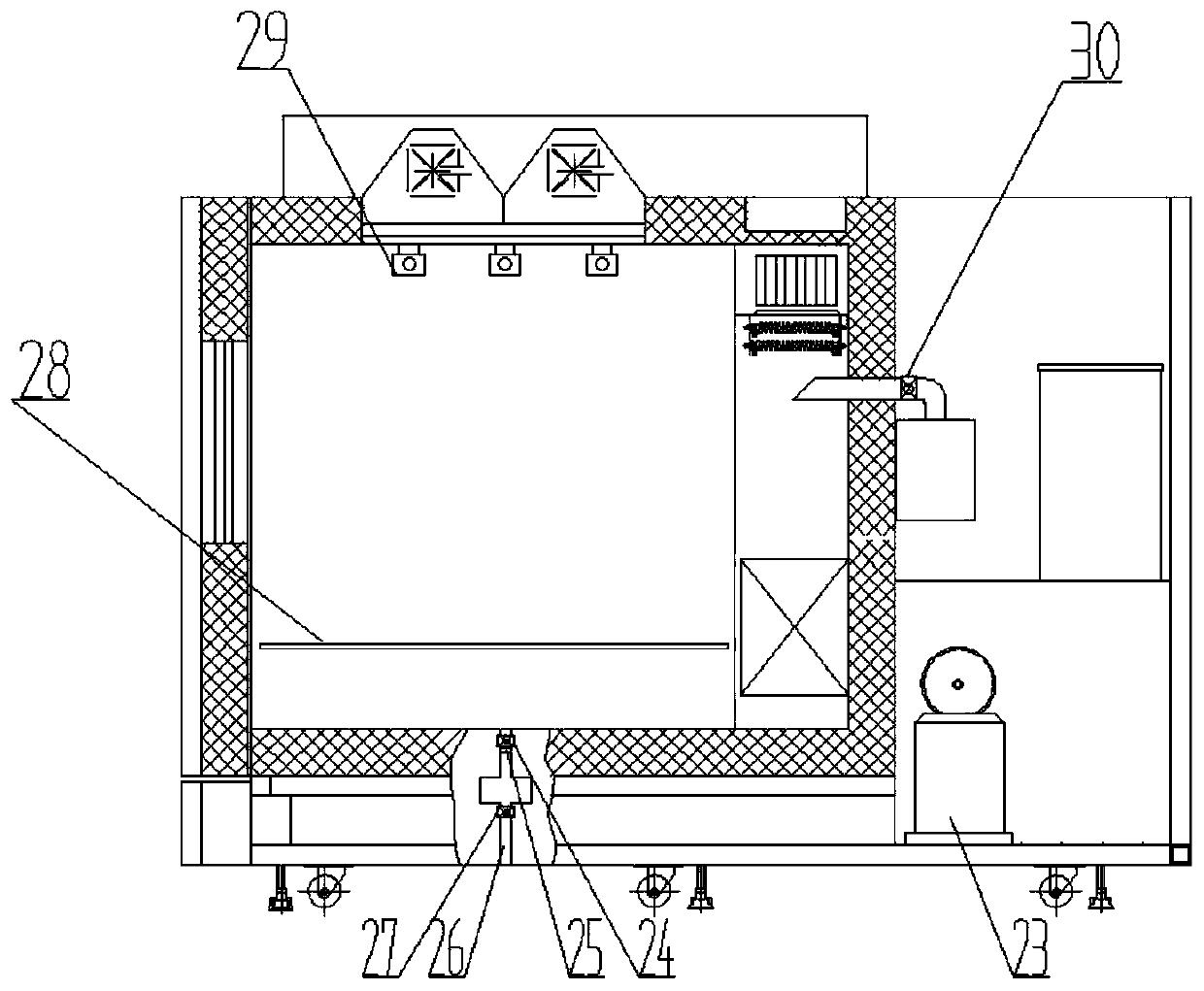

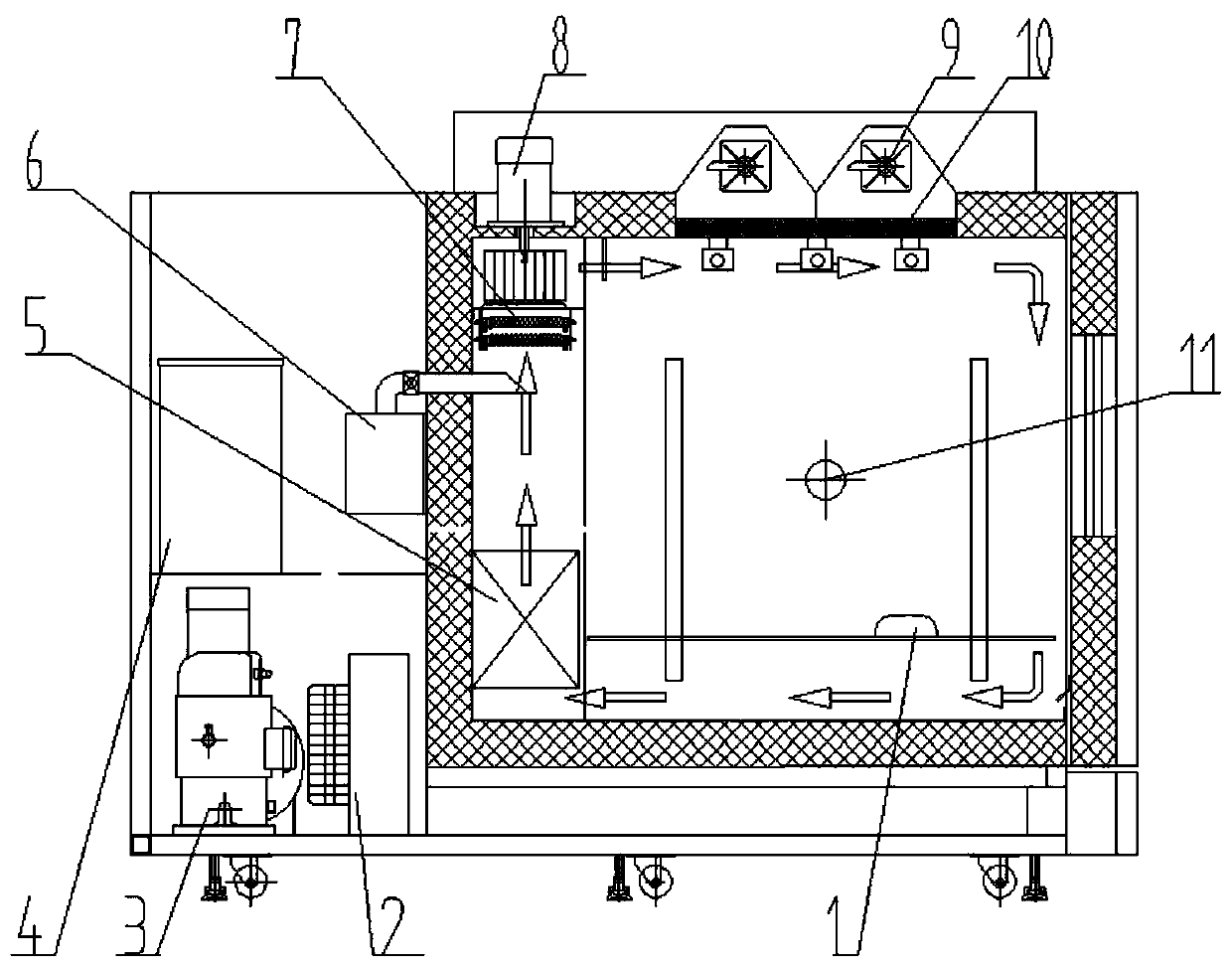

[0020] Embodiment 1: as Figure 1 to Figure 3 As shown, a multi-factor comprehensive plateau alpine climate environment simulation accelerated test device, the device includes a test box, an air pressure system, a light source system, a temperature and humidity adjustment system, a circulating air system and a control system. The test box is an inner pressure-bearing container, and the top of the container is composed of a high-transparency and high-strength glass plate 10 and a metal pressure-bearing net, and the high-transparency and high-strength glass plate is installed above the metal pressure-bearing net. An automatic drain valve 24 is installed at the bottom of the test box, through the automatic opening and closing of the upper solenoid valve 25 and the lower solenoid valve 27, the liquid accumulation formed during the test process is automatically removed through the drain pipe 26.

[0021] Described pneumatic system is made up of vacuum pump 23, solenoid valve and co...

Embodiment 2

[0026] Embodiment 2: The difference from Embodiment 1 is that the light source 9 is a combination of a metal halide lamp and an ultraviolet fluorescent lamp. Each lamp in the light source 9 can be turned on individually or simultaneously, and the power of each lamp can be adjusted within a certain range. The metal halide lamp in the light source 9 is installed on the top of the test chamber, above the high-transparency glass; the ultraviolet fluorescent lamp 29 is installed under the high-transparency glass, and is protected by a quartz tube to ensure that the ultraviolet fluorescent lamp can work normally under the harsh environmental conditions in the chamber. Work. Combination and power are controlled by PLC, single chip microcomputer or PC program.

[0027] By controlling some environmental factors, the present invention can also simulate cold area environment, hot and dry environment, tropical rainforest environment and aerial environment, etc.; this device can be used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com