Micro-light-emitting diode display panel, preparation method of micro-light-emitting diode display panel, spliced display panel and device

A technology of micro-light-emitting diodes and display panels, which is applied in the direction of identification devices, instruments, electrical components, etc., can solve the problems that affect the production yield of products, difficult to control the chamfer size, and difficult to realize the process, so as to improve the production yield, The effect of reducing size and reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

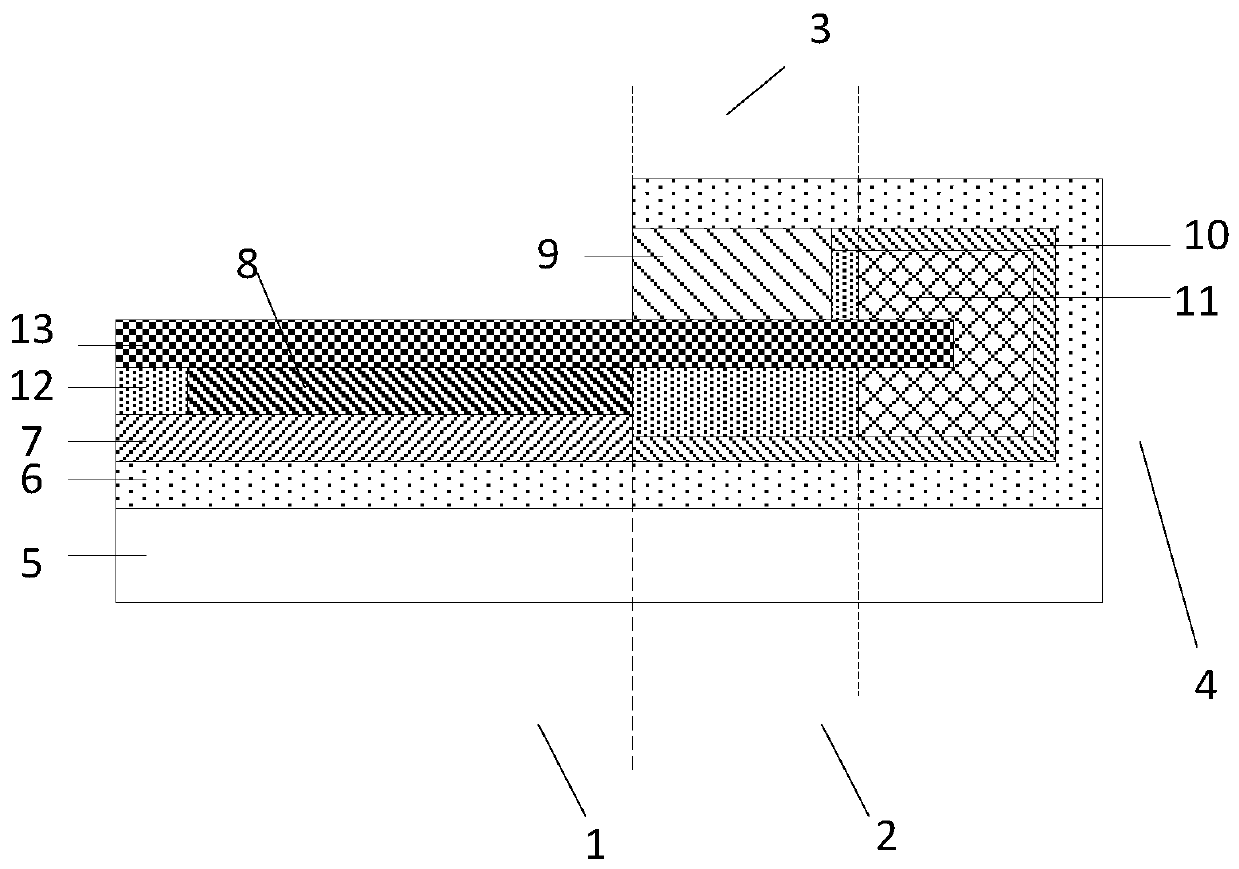

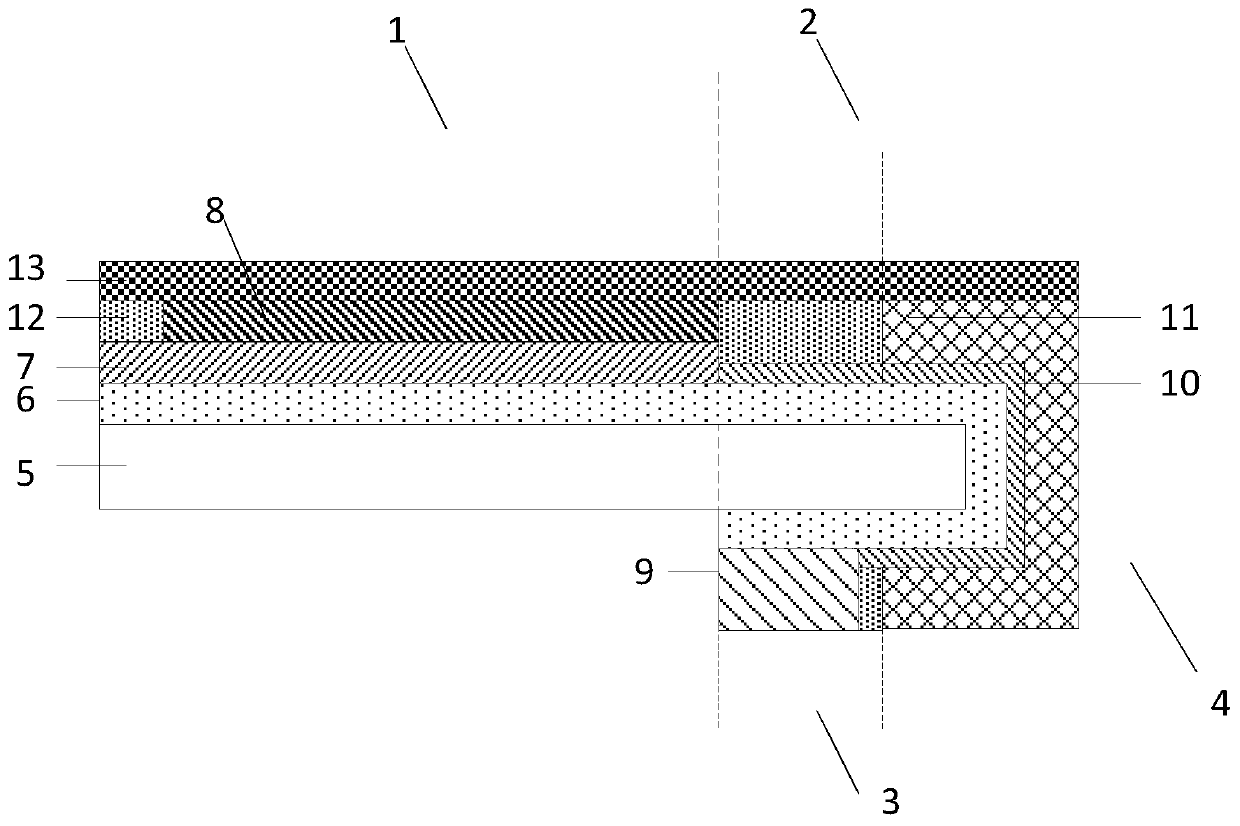

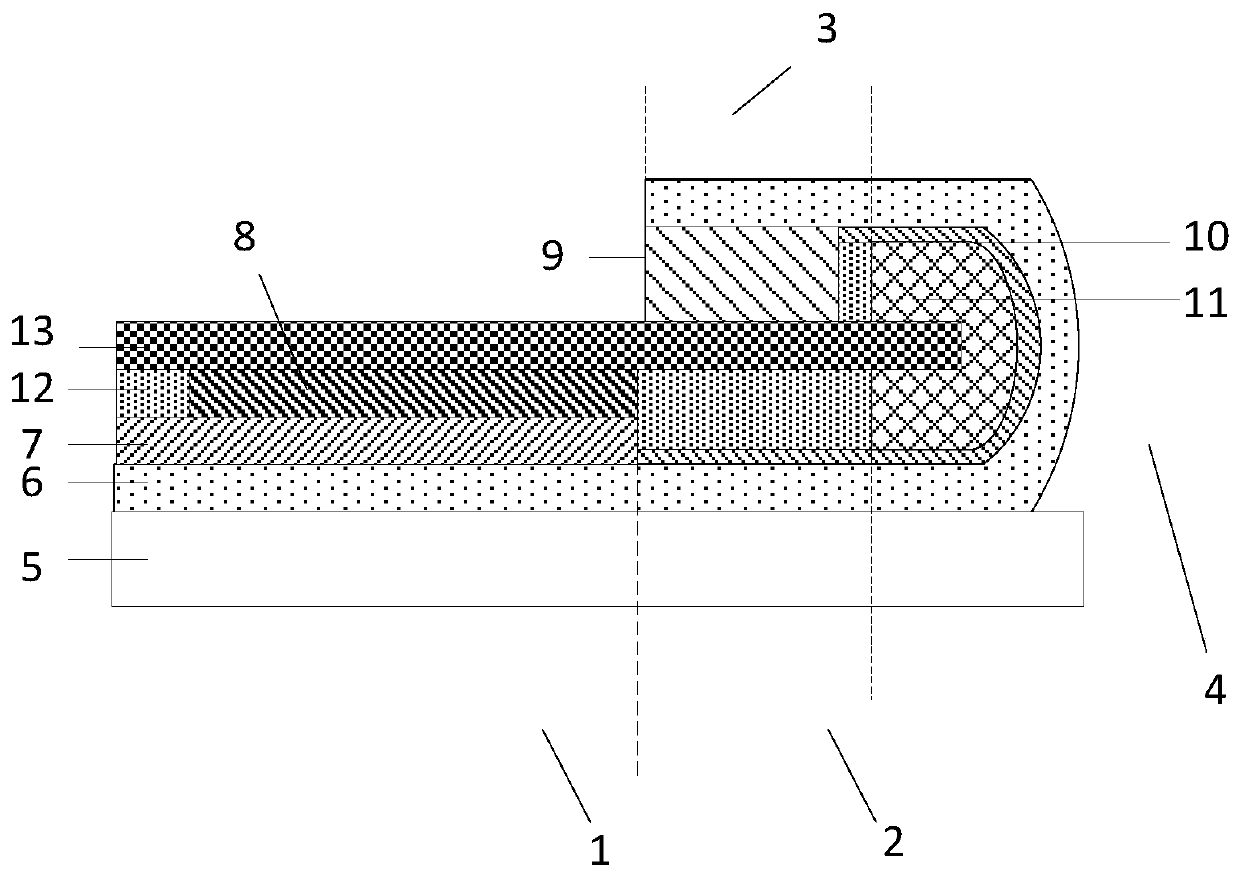

[0060] The embodiment of the present application provides a micro light emitting diode display panel, such as figure 1 As shown, the micro light emitting diode display panel is divided into: a display area 1 and a peripheral area 2 outside the display area 1; the peripheral area 2 includes: a fan-out area 3, and a peripheral area located in the fan-out area 3 and the bending area 4 between the display area 1;

[0061] The display area 1 includes: a base substrate 5, a flexible buffer layer 6 on the base substrate, a pixel circuit 7 on the flexible buffer layer 6, and a pixel circuit 7 on the pixel circuit 7. micro light emitting diode device 8;

[0062] The flexible buffer layer 6 extends to the peripheral area 2;

[0063] The fan-out area 3 further includes: a driving circuit 9 located on the flexible buffer layer 6;

[0064] The bending area 4 also includes: a lead 10 on the flexible buffer layer 6 electrically connecting the pixel circuit 7 and the driving circuit 9, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com