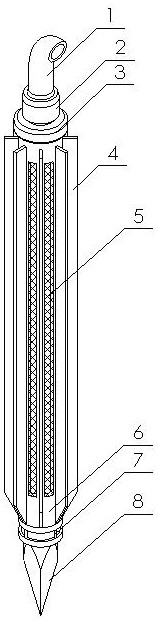

A granary grain heat dissipation insert rod

A grain and inserting rod technology, which is applied in agricultural machinery and tools, horticulture, climate change adaptation, etc., can solve the problems that are not suitable for the use of large granaries, and achieve the effect of improving heat dissipation efficiency, reducing labor intensity, and reducing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

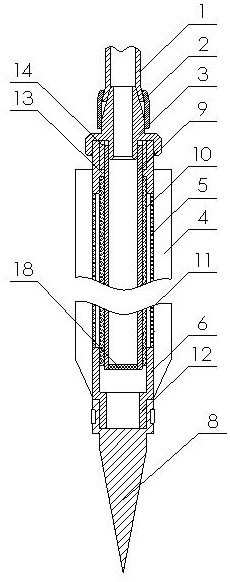

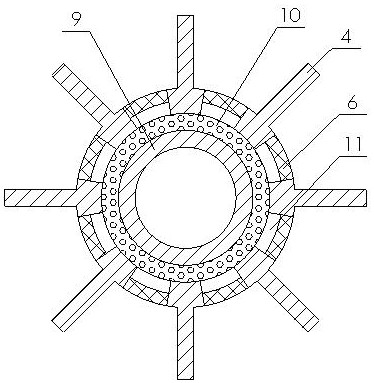

[0021] The granary grain heat dissipation insert rod of the present invention is realized in the following way: the granary grain heat dissipation insert rod of the present invention is composed of an exhaust pipe (1), a buckle sealing cap (2), a connector (3), a heat conducting sheet (4), a Net (5), connecting rod (6), temperature and humidity sensor (7), insertion tip (8), connecting pipe (9), water-absorbing layer (10), ventilation groove (11), connecting coil (12), limiting Position ring (13), sealing sleeve (14) and dust filter (18), one end of the connecting coil (12) is placed at the bottom of the connecting rod (6), the connecting rod (6) is a hollow structure, and the connecting rod (6) It communicates with the connecting coil (12), the upper end of the insertion tip (8) is a sleeve-like structure, and is screwed with the connecting coil (12), and the upper end of the insertion tip (8) is outside the sleeve-like structure. A plurality of temperature and humidity senso...

Embodiment 2

[0026] The difference between this embodiment and Embodiment 1 is: the heat conduction auxiliary sheet (17) is placed on both sides of the heat conduction sheet (4), and the heat conduction auxiliary sheet (17) and the heat conduction sheet (4) are integrally formed; , increase the overall heat absorption and heat dissipation area, and improve the heat dissipation effect on the heat points of the grain pile;

[0027] The outer side of the lower end of the heat conduction sheet (4) is a slope, and the slope is designed to be inclined upward from bottom to top, which is convenient for the lower end of the heat conduction sheet (4) to be inserted into the grain pile when inserted;

[0028] The heat conduction sheet (4) is equipped with a design of barbs, the barbs can be hung on the grain, improving the stability of inserting the rod into the grain pile;

[0029] The thickness of the screen (5) is designed to be smaller than the thickness of the ventilation groove (11), so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com