A method for preparing in situ tissue engineering blood vessels by a composite process

A technology of tissue engineering and composite technology, applied in the field of biomedical tissue engineering, to achieve the effect of simple and feasible removal steps, guaranteed mechanical properties, and increased heparin molecular binding sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] like Figure 5 As shown, a method for preparing in situ tissue engineered blood vessels by a composite process comprises the following steps:

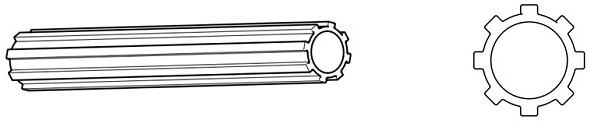

[0037] a. 3D printing water-soluble materials to prepare stent collection rods: the structure is a cylindrical hollow structure, such as figure 1 As shown: the inner diameter is 3.5mm, the outer diameter is 4.5mm, and the outer surface of the cylinder is designed with 8 ridges. The size of the raised structure is 50mm in length, 0.4mm in width, and 0.2mm in height. The collection rod is made of polyvinyl alcohol, a water-soluble polymer material Shaped by FDM printing. The nozzle temperature of the printer is 160°C, the bed temperature is 60°C, the nozzle moving speed is 20mm / s, and the layer thickness is set to 0.15mm.

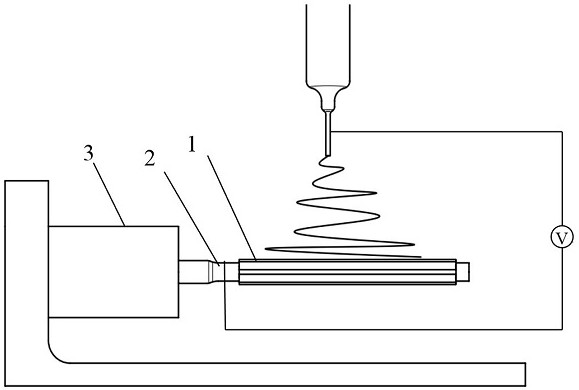

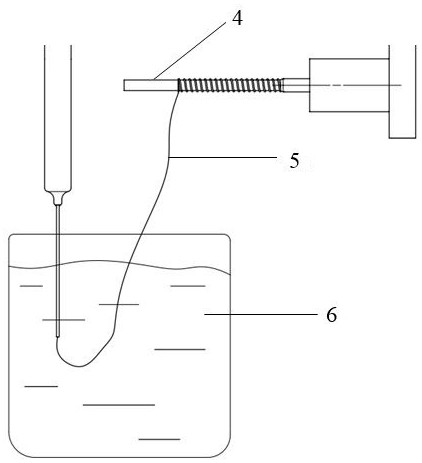

[0038] b. The inner layer of tissue engineering blood vessels was prepared by electrospinning process, such as figure 2 Shown: To increase the number of end groups available for biomolecular attachment, pol...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, and the special features are:

[0046] In this embodiment, a method for preparing in situ tissue engineered blood vessels by a composite process is to prepare ridges of different widths and numbers on the outside of the stent collection rod to cause patterning of the inner layer of the stent, including the following steps:

[0047] a. 3D printing water-soluble materials to prepare vascular stent collection rods: design vascular stent collection rods: its structure is a cylindrical hollow structure with an inner diameter of 4mm and an outer diameter of 5mm, and 6 ridges are designed on the outer surface of the cylinder, and the size of the raised structure is long 50mm, 0.5mm wide, and 0.3mm high, the collection rod is made of water-soluble polymer material polyvinyl alcohol and formed by FDM printing. The nozzle temperature of the printer is 160°C, the bed temperature is 60°C, the nozzle moving speed is 20mm / s, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com