Size control method for high-precision roll-formed part

A technology of size control and roll forming, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of material waste, uneven thickness, and reduced effective utilization of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

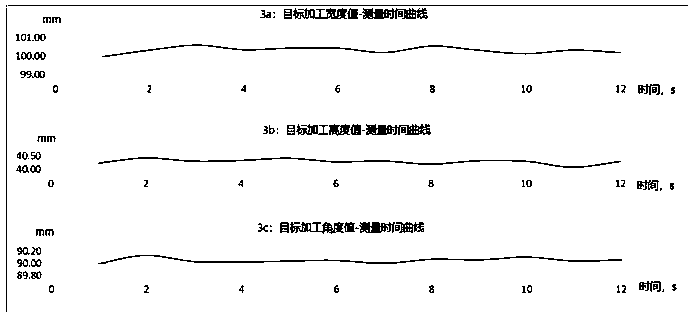

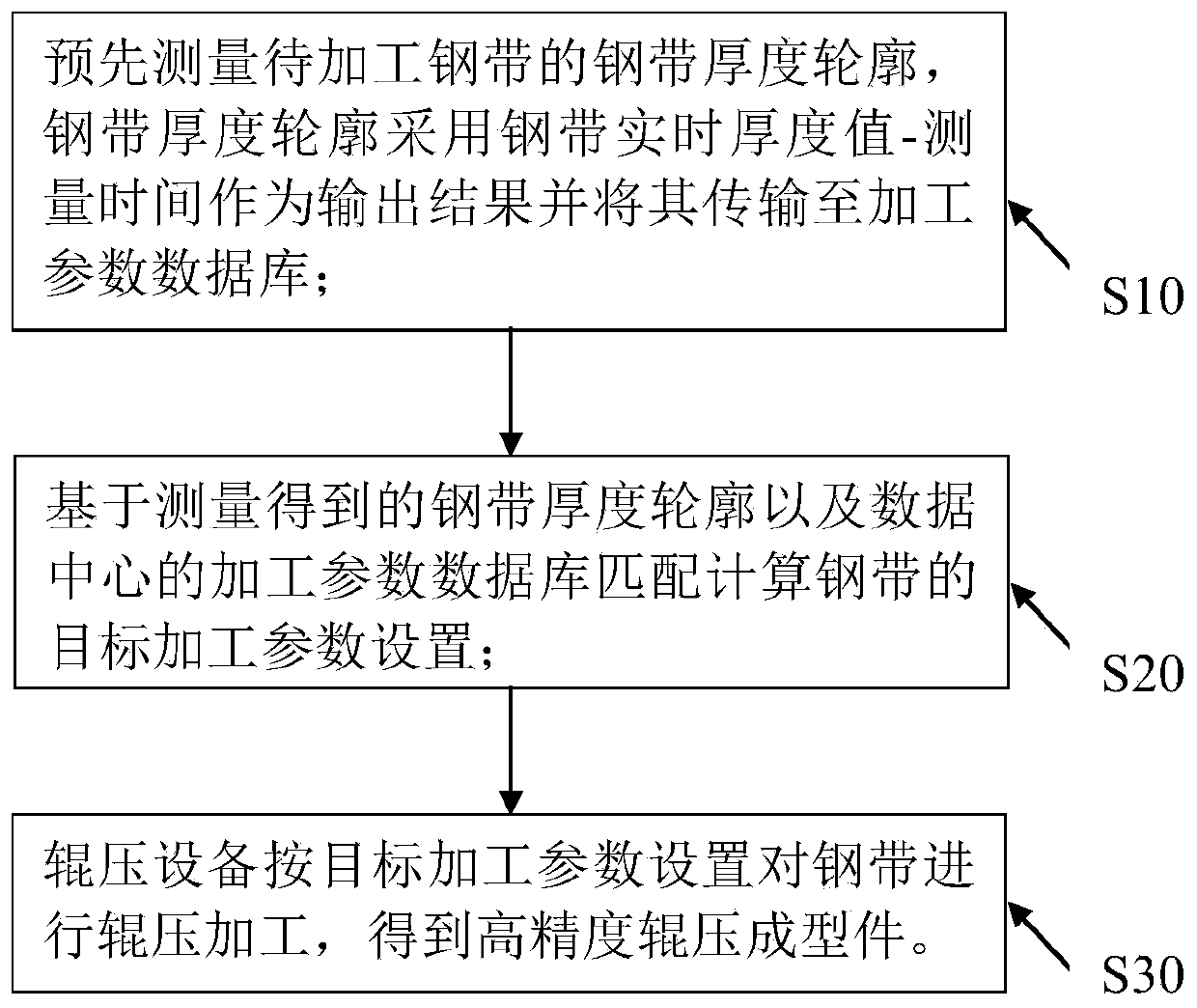

[0042] Example 1: see figure 1 shown, and in conjunction with Figure 5 and Figure 6 As shown, a method for controlling the size of a high-precision roll-formed part uses a steel strip 210 to obtain a high-precision roll-formed part 220 through a roll-forming process. The steel strip 210 is made of advanced high-strength steel materials. Among them, the steel strip 210 is in the roll forming state of continuous feeding, and its control steps include:

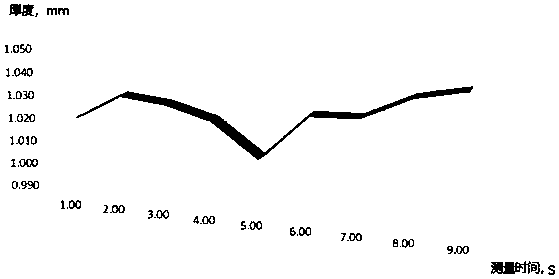

[0043] S10), pre-measure the steel strip thickness profile of the steel strip 210 to be processed, please refer to figure 2 As shown, the steel strip thickness profile adopts the steel strip real-time thickness value-measurement time curve as the output result and outputs it to the processing parameter database; further preferably, in this step S10), the steel strip thickness profile measurement device is used to measure the steel strip to be processed The steel strip thickness profile, the output end of the steel strip thi...

Embodiment 2

[0057] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that please refer to Figure 7 As shown, preferably, in this embodiment 2, the control step also includes step S40), measuring the actual value of the processing parameter of the high-precision roll-formed part, and comparing the actual value of the processing parameter with the target processing parameter determined in step S20). Compare and calculate the difference, use the difference=0 as the control target, adjust the steel strip thickness profile processing matching curve, to reduce or eliminate the contrast difference of the next steel strip processing to be processed; this embodiment optimizes the steel strip through real-time online adjustment The processing matching curve with thickness contour can further effectively improve the matching calculation accuracy of the processing parameter database.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com