Gantry movable pipe plate chamfering lathe

A mobile, tube sheet technology, applied in the field of machinery, can solve the problems of high manufacturing cost, reduce manufacturing difficulty and manufacturing cost, etc., and achieve the effects of convenient operation, reduced manufacturing difficulty, and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

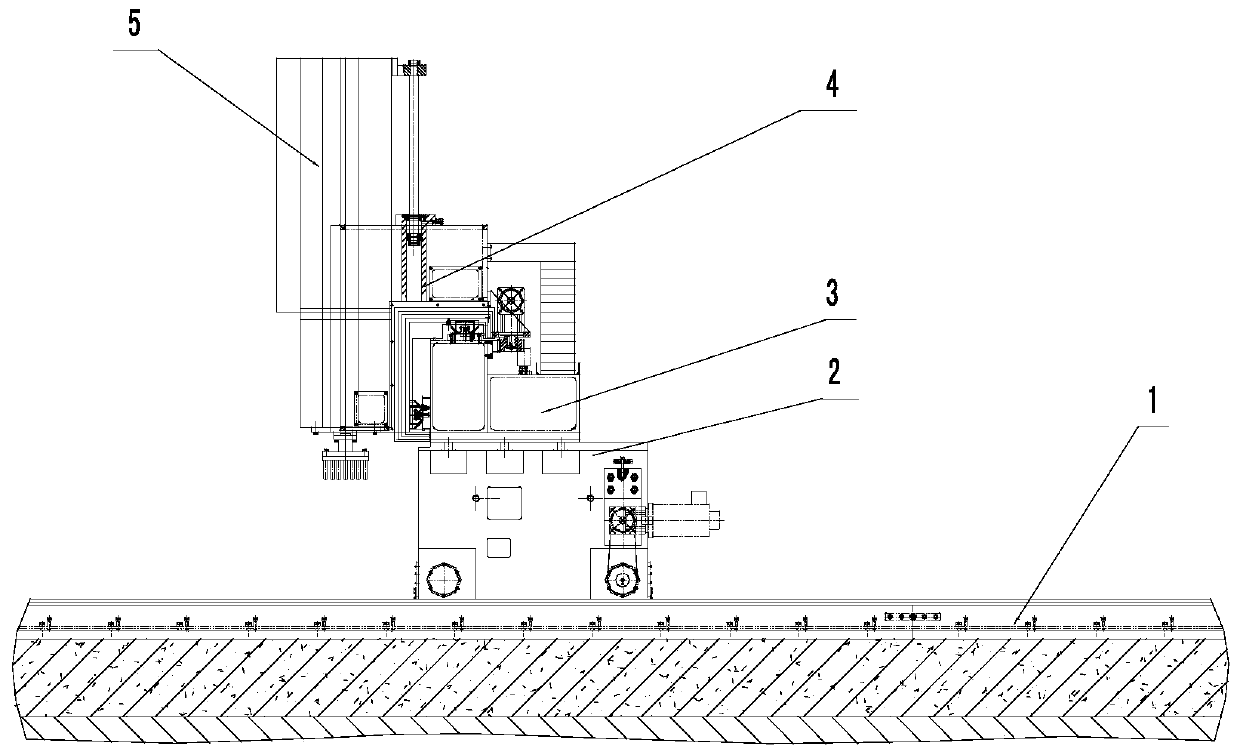

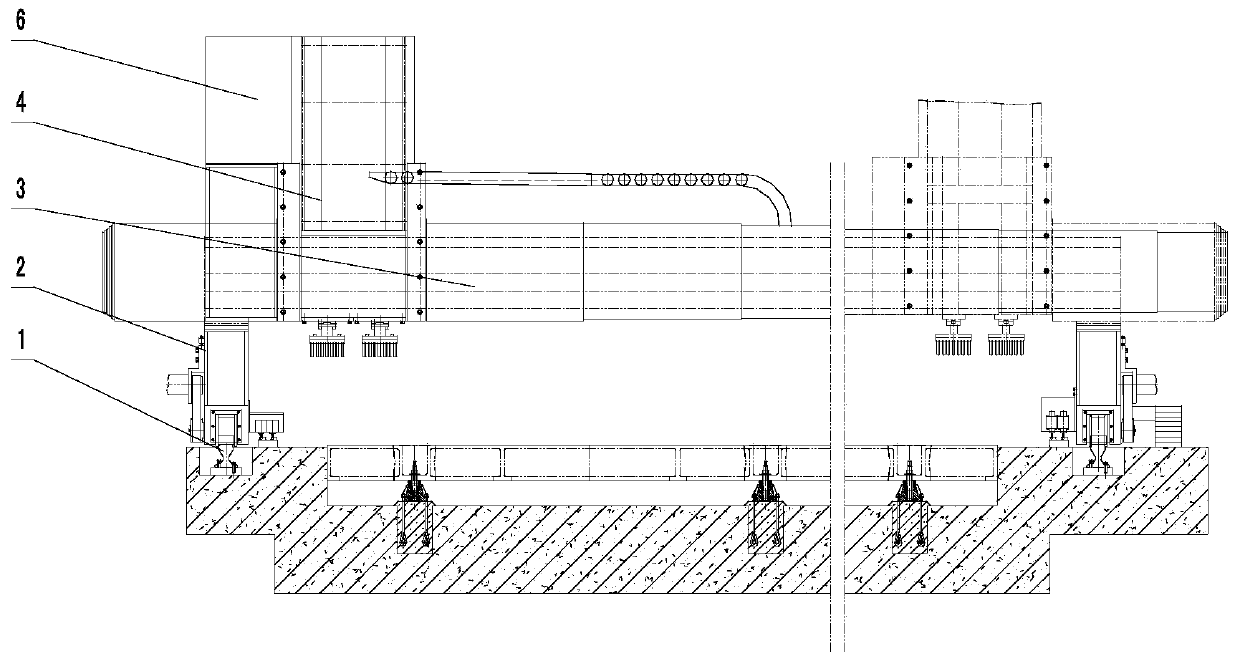

[0012] Depend on figure 1 , figure 2 As shown, a gantry mobile tube plate chamfering lathe includes a guide rail 1, a gantry frame 2 is connected to the guide rail 1, a beam 3 is arranged on the gantry frame 2, a beam slide seat 4 is connected to the beam 3, and a beam slide seat 4 is connected to the beam slide The seat 4 is connected with a ram 5 . The guide rail 1 is welded by three sections of I-shaped steel, the total length of the guide rail is 11100mm, the guide rail is connected with the foundation through the anchor screws, so that the guide rail has sufficient rigidity, and the structure at the anchor screws is in the form of one pull and one top, so that there is It is beneficial to the installation and adjustment of the I-beam guide rail. The gantry 2 includes two columns on the left and right. The columns are welded by steel plates. The bottom of one column...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap