A variable-section spring blank, processing tooling and processing technology

A processing technology and variable cross-section technology, applied to springs, springs/shock absorbers, coil springs, etc., can solve problems such as spring damage, achieve the effects of reducing weight, prolonging service life, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

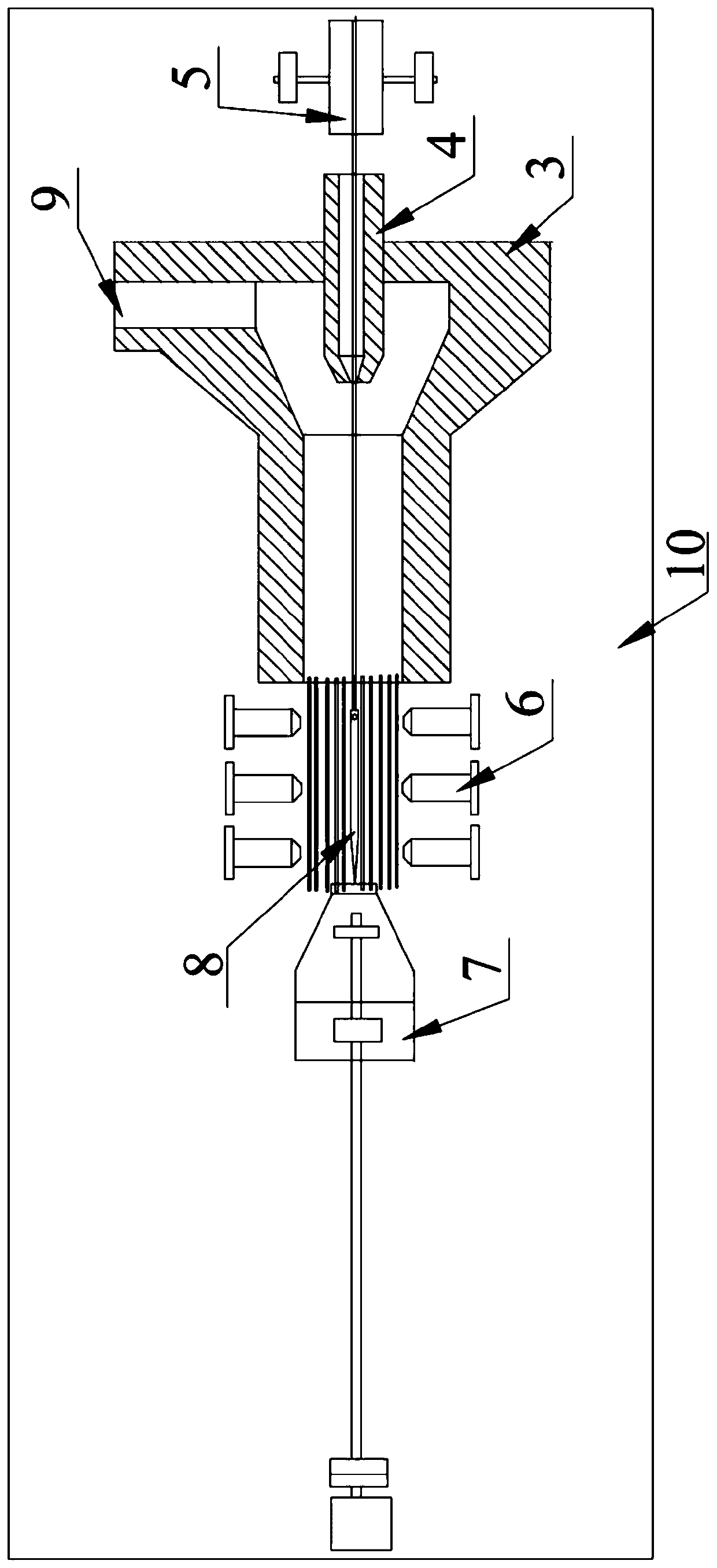

[0034] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

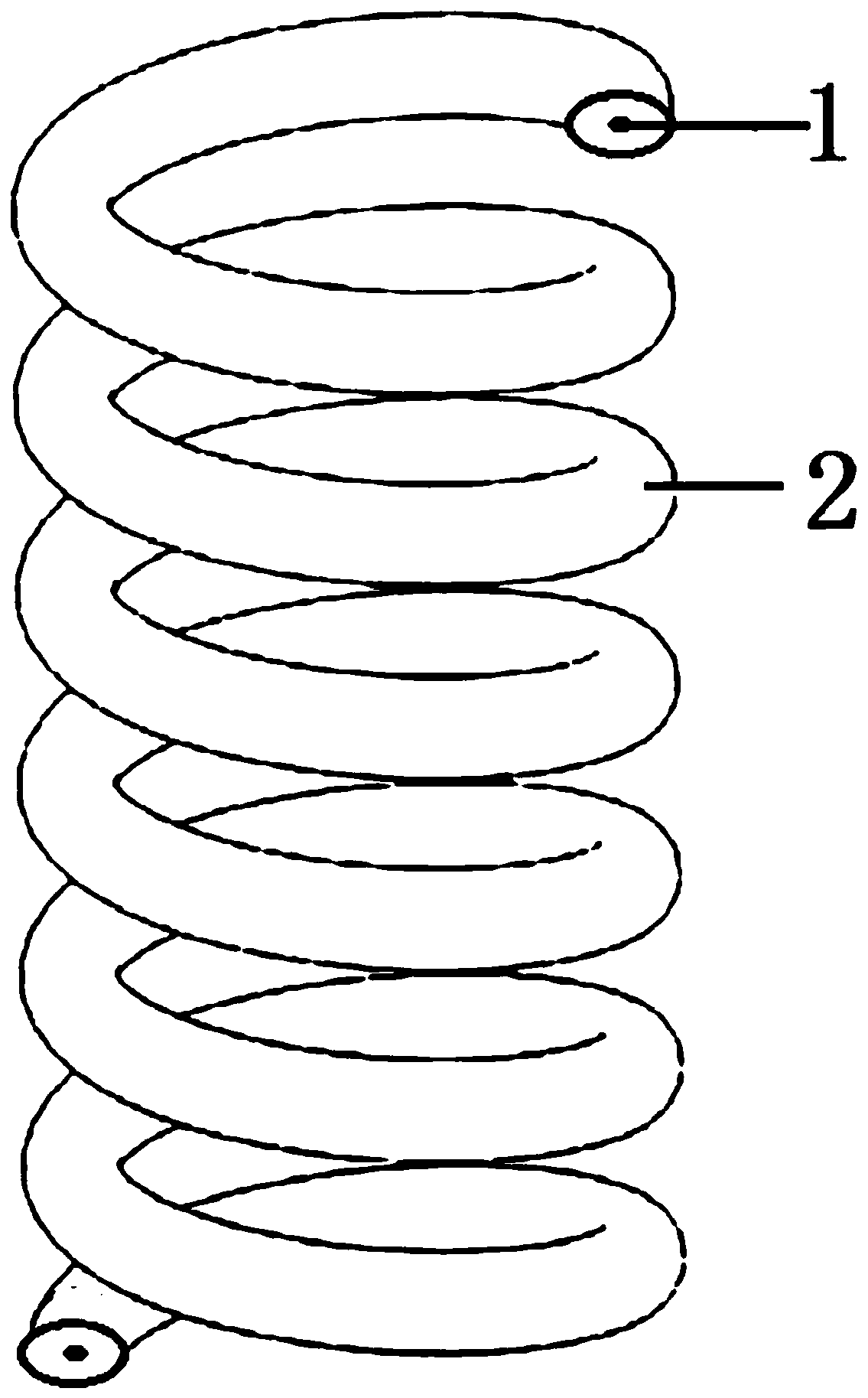

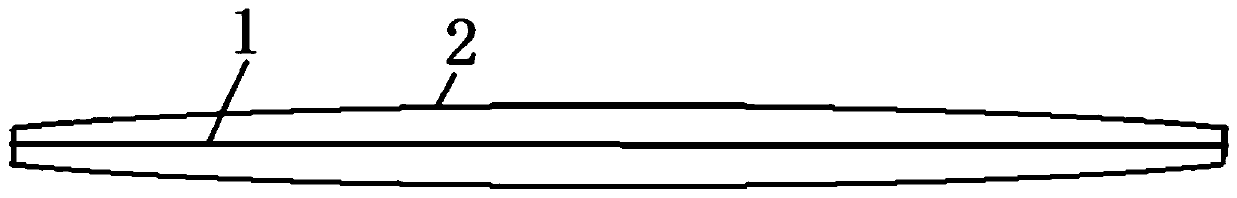

[0035] Such as figure 1 , 2 As shown, the present invention is a spring blank 2 with variable cross-section. The spring blank 2 is a coil spring blank. Carbon fiber mandrel 1 buried inside the spring material.

[0036] In order to improve the tensile strength of the spring and facilitate the forming of the coil spring, a preferred embodiment of the present invention is that the carbon fiber mandrel 1 pre-embedded in the spring blank can have only one carbon fiber wire, or can be A plurality of carbon fiber threads, the preferred technical solution is 5-10.

[0037] In order to enable the coil spring to have a higher supporting function and to absorb the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com