High-performance carbon paper for fuel cell and preparation method and application thereof

A fuel cell, high-performance technology, applied in fuel cells, synthetic cellulose/non-cellulose material pulp/paper, paper, etc., can solve the problem of high resistivity of carbon paper, achieve good physical properties, improve physical properties, reduce The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

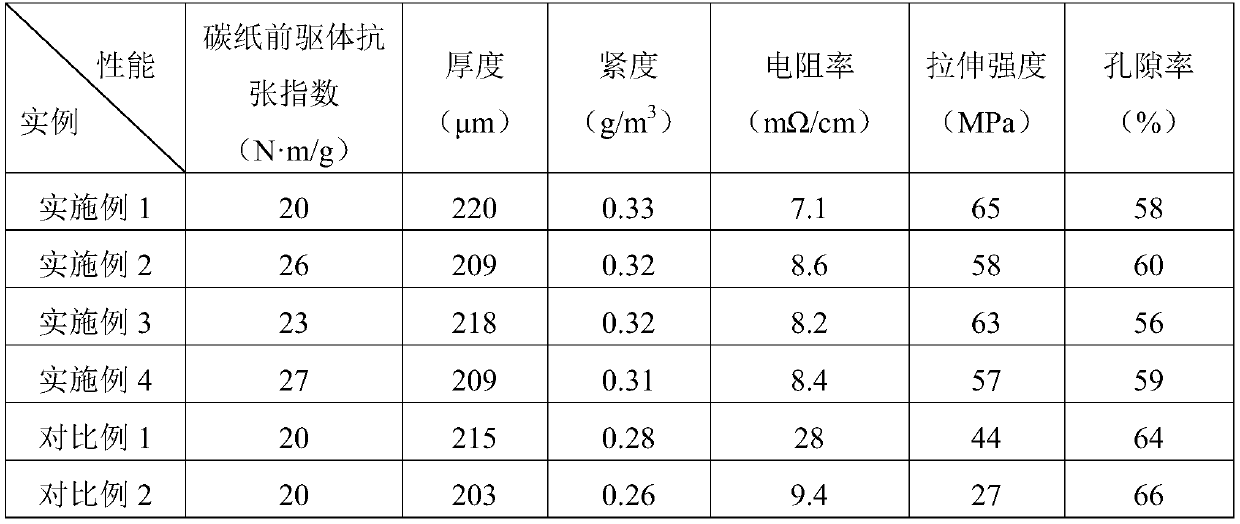

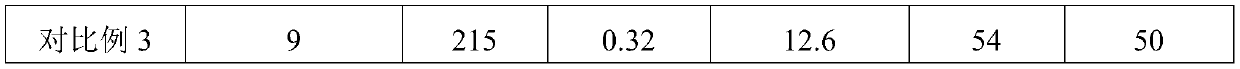

Examples

preparation example Construction

[0053] The preparation method of the acid-modified carbon nanotubes involved in the present invention is as follows: carbon nanotubes (Nanjing Xianfeng Nano Material Technology Co., Ltd., multi-walled carbon nanotubes diameter 10 ~ 20nm, length 10 ~ 30μm) and mixed acid (mass Fraction 98% concentrated sulfuric acid and mass fraction 68% concentrated nitric acid (mass ratio 3:1) solution is added in the single-necked round bottom flask with condensation reflux device, wherein, carbon nanotube accounts for 2.5% of the mass fraction of mixed acid solution, is heated to 120 ℃ , kept for 5 hours, and then the carbon nanotubes were washed with deionized water to obtain acidified multi-walled carbon nanotubes.

[0054] The preparation method of carbon nanotubes involved in the present invention, boric acid-cardanol modified phenolic resin is as follows:

[0055] ① Add phenol, boric acid and acetic acid in a certain proportion to a three-necked flask equipped with a thermometer, agita...

Embodiment 1

[0059] (1) Get 10 parts by mass of viscose fiber (Hubei Chemical Fiber Factory, length 3mm), 2 parts by mass of cellulose nanofibrils (NFC, purchased from KEXLAN), 88 parts by mass of carbon fiber (Japan Teijin Corporation, polyacrylonitrile-based carbon fiber, Length 6mm, resistivity 1~10mΩ / cm) into the dispersion barrel with agitator, add appropriate amount of water to make the total mass fraction of viscose fiber, cellulose nanofibril and carbon fiber 0.15%, start stirring, the speed is 700rpm , first add 0.04wt% Tween-80, then add 0.12wt% polyethylene oxide (PEO, molecular weight 6,000,000), and add 0.13wt% polyvinyl alcohol solution (PVA, molecular weight 170,000 to 220,000) (the concentration of polyvinyl alcohol solution is 10% by mass), after mechanical stirring for 10 minutes, wet paper web is made by wet forming equipment, and dried in an oven (temperature 90 ~ 110 ° C, time 30 ~ 40 minutes), Made of quantitative 90g / m 2 carbon paper precursors.

[0060] (2) The ca...

Embodiment 2

[0062] (1) Get 15 parts by mass of viscose fiber (Hubei Chemical Fiber Factory, length 3mm), 1 part by mass of cellulose nanofibrils (NFC, purchased from KEXLAN), 84 parts by mass of carbon fiber (Teijin Corporation, polyacrylonitrile-based carbon fiber, Length 6mm, resistivity 1~10mΩ / cm) into the dispersion barrel with agitator, add appropriate amount of water to make the total mass fraction of viscose fiber, cellulose nanofibril and carbon fiber 0.15%, start stirring, the speed is 700rpm , first add 0.04wt% Tween-80, then add 0.12wt% polyethylene oxide (PEO, molecular weight 6,000,000), and add 0.13wt% polyvinyl alcohol solution (PVA, molecular weight 170,000 to 220,000) (the concentration of polyvinyl alcohol solution is 10% by mass), after mechanical stirring for 10 minutes, wet paper web is made by wet forming equipment, and dried in an oven (temperature 90 ~ 110 ° C, time 30 ~ 40 minutes), Made of quantitative 90g / m 2 carbon paper precursors.

[0063] (2) The carbon pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com