Pointer type sprinkling machine water delivery steel pipe pressing and binding device

A sprinkler and pointer technology, which is applied in watering devices, horticulture, botany equipment and methods, etc., can solve the deviation of water delivery steel pipes, the trouble of unified procurement and installation of rubber pipes, and the impact on the span of pointer sprinklers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

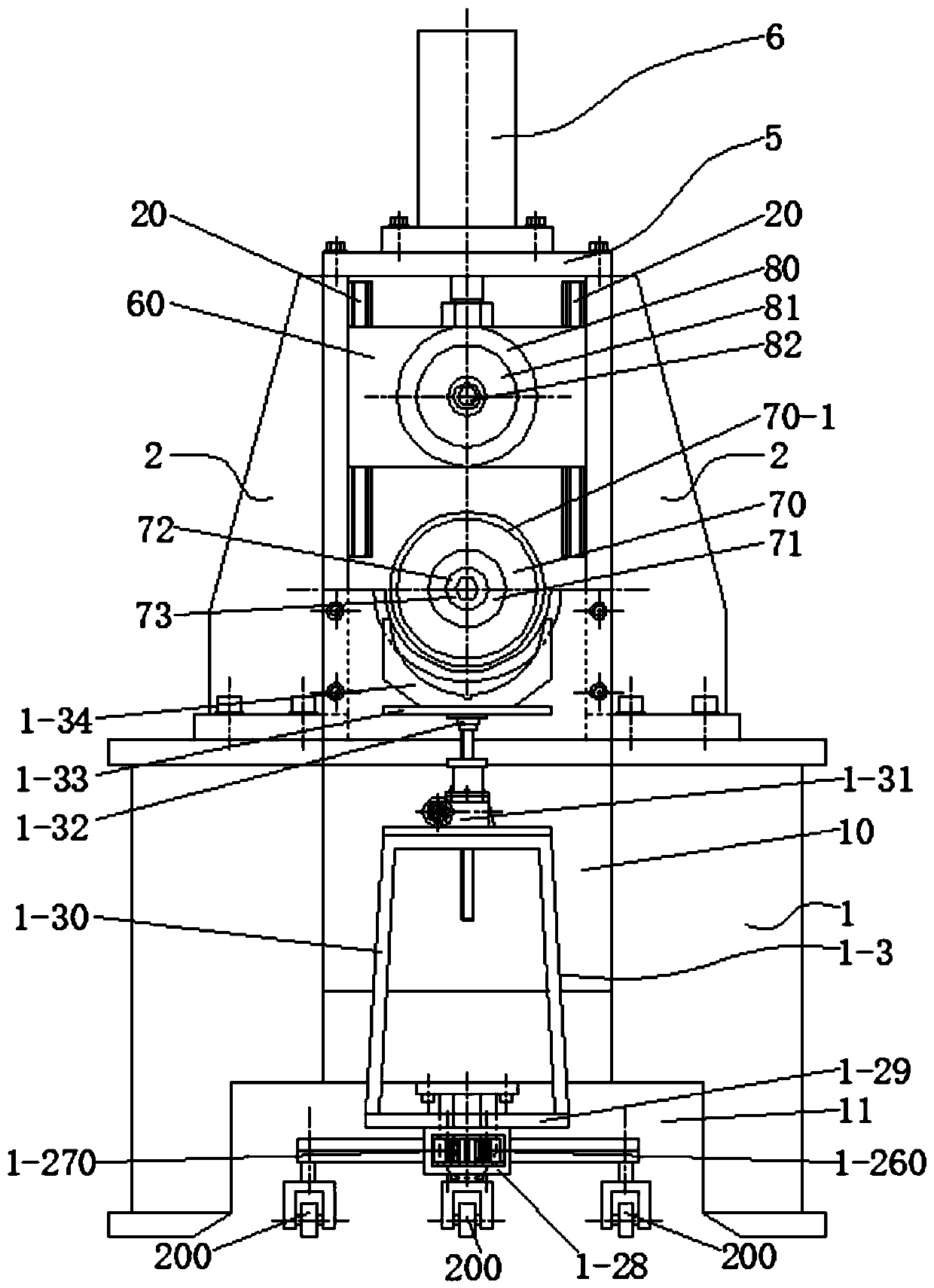

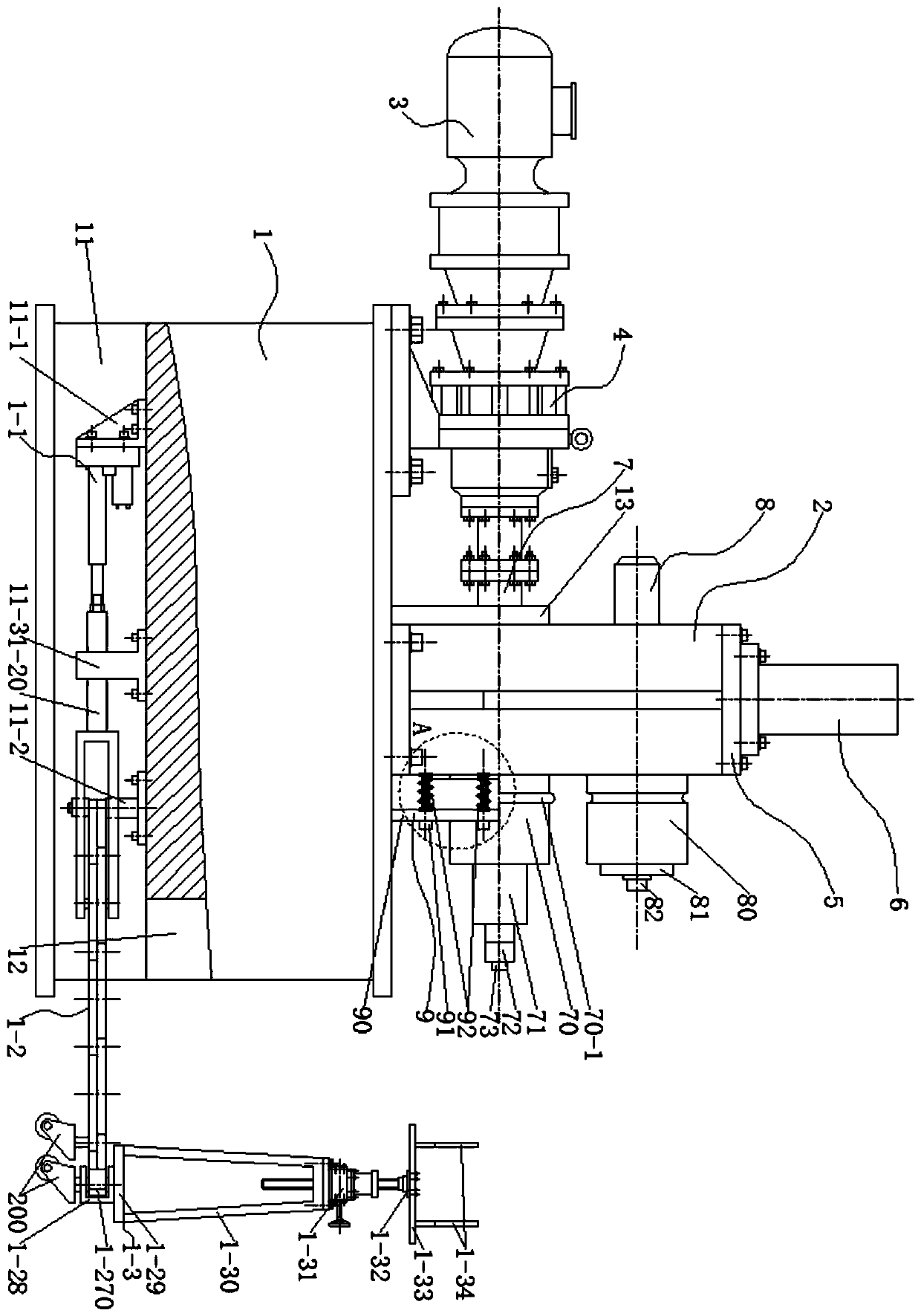

Embodiment 1

[0072] According to the water delivery steel pipe pressure hoop device of the pointer type sprinkler irrigation machine, the micro electric push rod is activated according to the length of the water delivery steel pipe to be pressed, and the push rod of the micro electric push rod pushes the push frame to move forward, so that the cylinder on the push frame The rod moves forward under the guidance of the guide seat; because the front end of the fork rod 1-202 is hinged with the center hinge of the scissor rod one 1-23, the connecting rod one 1-21 and the connecting rod two 1-22 One end is hinged with the support two 11-2 at the same time, the other end of the connecting rod one 1-21 is hinged with the left rear end of the scissor rod one 1-23, and the other end of the connecting rod two 1-22 is connected with the scissor rod one 1-23 The right rear end is hinged, the left front end of the scissor lever 1-23 is hinged with the left rear end of the scissor lever 2 1-24, the right...

Embodiment 2

[0080] On the basis of Embodiment 1, a cavity 11 is provided below the workbench 1, and a notch 12 is provided at the front end of the workbench 1. When the equipment is not in use, the push rod of the miniature electric push rod 1-1 pulls and pushes The frame 1-20 moves backwards, so that the cylindrical rod 1-200 on the push frame 1-20 moves backward under the guidance of the guide seat 11-3, and then the push frame 1-20, connecting rod one 1-21, Connecting rod 2 1-22, scissor rod 1 1-23, scissor rod 2 1-24, scissor rod 3 1-25, connecting rod 3 1-26 and connecting rod 4 1-27 are all stored in cavity 2 11, then the bracket 1-3 is accommodated in the notch 12 along with the hinged seat 1-28, realizing the storage of the multiplying telescopic mechanism 1-2 and the bracket 1-3, and occupying a small space.

Embodiment 3

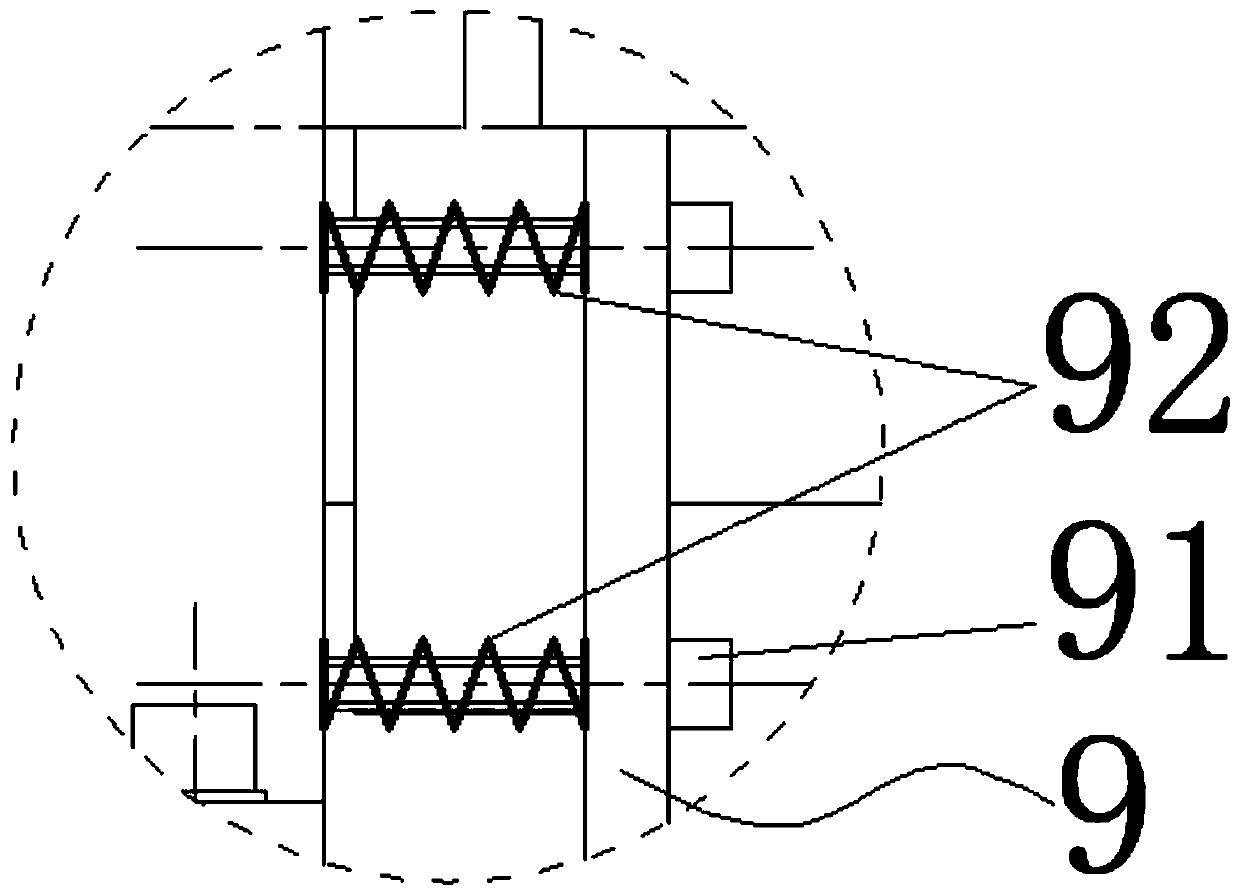

[0082] On the basis of Embodiment 1, the limiting mechanism 9 is composed of a limiting plate 90, an adjusting bolt 91 and a compression spring 92. A limiting step 90-1 is provided on the back of the limiting plate 90, and a There is a cylindrical hole 90-2, the adjusting bolt 91 passes through the cylindrical hole 90-2, and then the compression spring 92 is put on and screwed on the side bracket 2, one end of the compression spring 92 is in contact with the side bracket 2, and the other end is in contact with the limiter. The position plate 90 contacts, according to the distance between the rolling convex ring and the end of the water delivery steel pipe, screw the adjusting bolt 91 to change the distance between the limit plate 90 and the side bracket 2, thereby changing the distance between the limit step 90-1 and the convex hoop 70-1 Take the steel ruler to measure the distance between the upper and lower sides of the limit plate 90 and the side bracket 2, so that the dimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com