Hot press molding method for bamboo plates

A hot-press forming and plate technology, applied in the pretreatment of forming materials, flat products, manufacturing tools, etc., can solve the problems of high production cost, low utilization rate of bamboo materials, large amount of glue consumption, etc. The effect of uneven force and uniform width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

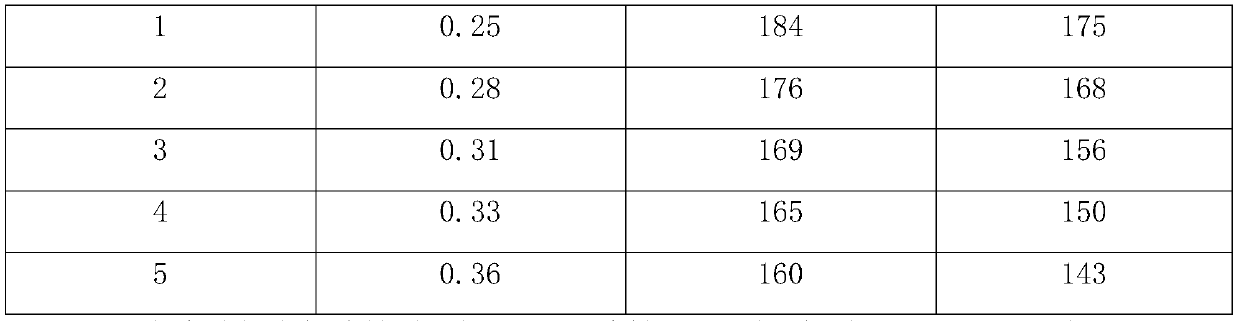

Embodiment 1

[0022] A kind of bamboo sheet thermocompression forming method, comprises the following steps:

[0023] (1) Put the glue-coated bamboo board blanks into the hot press machine with the same thickness of each layer, without overlapping, with the panel facing up;

[0024] (2) Each board is separated by steel bars, and the middle of the veneer is separated by bamboo slices; the thickness of the veneer made of bamboo board is 21mm;

[0025] (3) Control the temperature of the hot plate to 95°C, the main pressure is 10Mpa, the side pressure is 4Mpa, and the heat preservation and pressure holding time is 150s;

[0026] (4) Demould the hot-pressed bamboo boards, put the bamboo boards on the supporting board, and use three spacers in the middle of each bamboo board to evenly separate the heat from the bamboo boards, and get the required bamboo board after curing. sheet.

[0027] The bamboo board blank is coated on one side with curing glue, and the curing glue is prepared according to...

Embodiment 2

[0030] A kind of bamboo sheet thermocompression forming method, comprises the following steps:

[0031] (1) Put the glue-coated bamboo board blanks into the hot press machine with the same thickness of each layer, without overlapping, with the panel facing up;

[0032] (2) Each board is separated by steel bars, and the middle of the veneer is separated by bamboo slices; the thickness of the veneer made of bamboo board is 21mm;

[0033] (3) Control the temperature of the hot plate to 95°C, the main pressure is 10Mpa, the side pressure is 5Mpa, and the heat preservation and pressure holding time is 160s;

[0034] (4) Demould the hot-pressed bamboo boards, put the bamboo boards on the supporting board, and use three spacers in the middle of each bamboo board to evenly separate the heat from the bamboo boards, and get the required bamboo board after curing. sheet.

[0035] The bamboo board blank is coated on one side with curing glue, and the curing glue is prepared according to...

Embodiment 3

[0038] A kind of bamboo sheet thermocompression forming method, comprises the following steps:

[0039] (1) Put the glue-coated bamboo board blanks into the hot press machine with the same thickness of each layer, without overlapping, with the panel facing up;

[0040] (2) Each board is separated by steel bars, and the middle of the veneer is separated by bamboo slices; the thickness of the veneer made of bamboo board is 21mm;

[0041] (3) Control the temperature of the hot plate to 95°C, the main pressure is 10Mpa, the side pressure is 6Mpa, and the heat preservation and pressure holding time is 180s;

[0042] (4) Demould the hot-pressed bamboo boards, put the bamboo boards on the supporting board, and use three spacers in the middle of each bamboo board to evenly separate the heat from the bamboo boards, and get the required bamboo board after curing. sheet.

[0043] The bamboo board blank is coated on one side with curing glue, and the curing glue is prepared according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com