Stone roadway mining method and device and stone back cutting device for stone roadway mining

A technology of mining method and cutting device, which is applied in the direction of stone processing equipment, drilling equipment and method, drilling equipment, etc., can solve the problems of difficult stone cutting, low stone density, irregular backside, etc., and achieve low cost and high mining efficiency. High efficiency and regular effect on the back side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

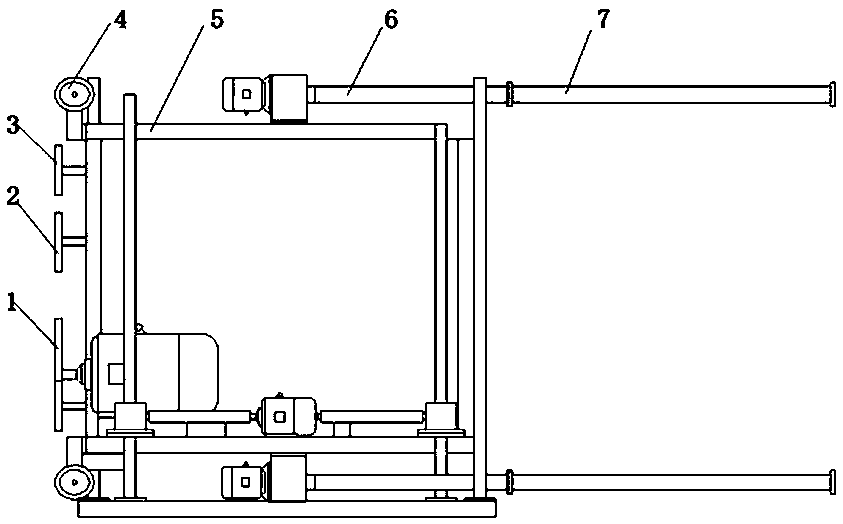

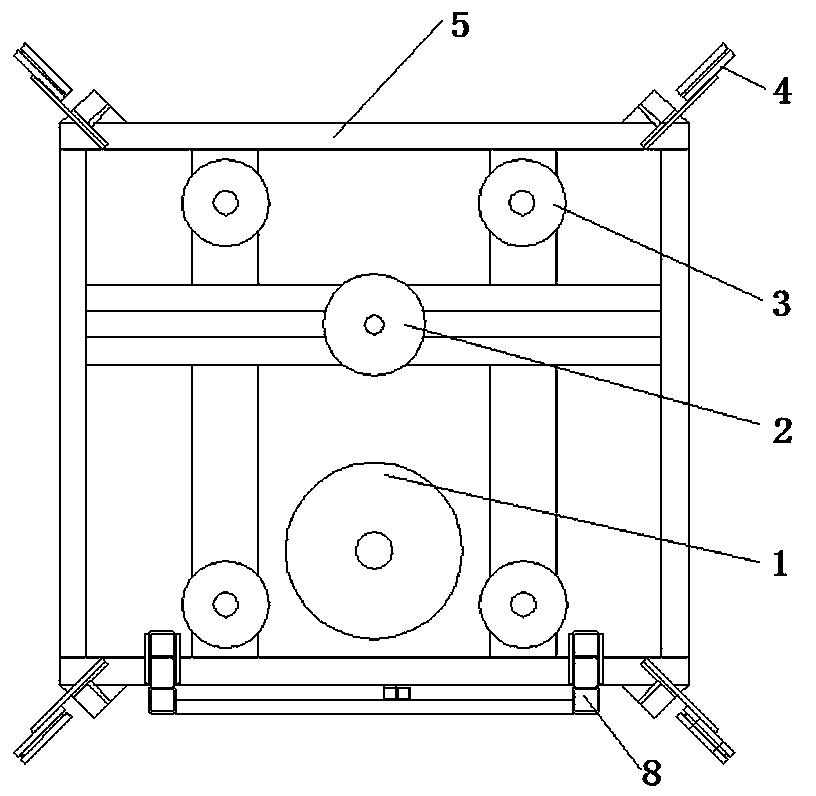

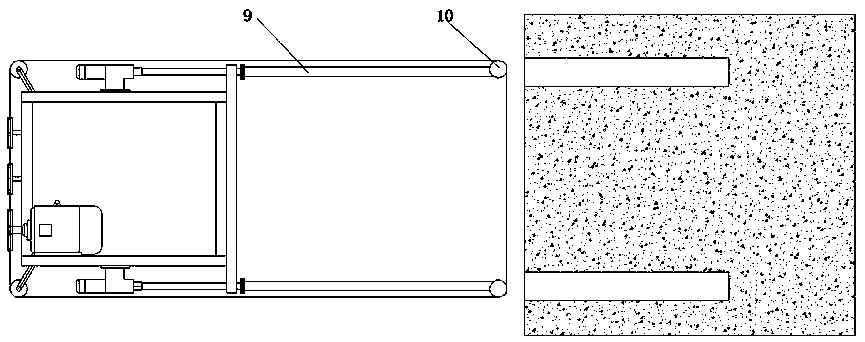

[0050] The present invention is described in detail below in conjunction with accompanying drawing:

[0051] Stone roadway mining method of the present invention is carried out as follows:

[0052] a. Drilling, drilling four holes on the stone wall of the roadway, and taking out the core;

[0053] b. Cut four sides, use emery beaded wire saw to connect the above four holes and cut two adjacent holes into one side, and cut out four sides;

[0054] c. Cut the back and cut out the back of the stone with an emery beaded wire saw.

[0055] After cutting out the back of the stone, take out the cut stone with a forklift.

[0056] The key points of the inventive method are: c. cut the back, and cut out the back of the stone with an emery beaded wire saw.

[0057] As a preference, what can make full use of the stone is that the four holes are equidistantly arranged in parallel. In this way, the front of the stone is a square, with four holes at the four corners of the square, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com