High-frequency suspension heat transfer printer without pressure

A thermal transfer machine, high-frequency technology, applied in rotary printing machines, printing machines, transfer printing and other directions, can solve the problems of inability to customize patterns, long transfer time, and inability to meet individual needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

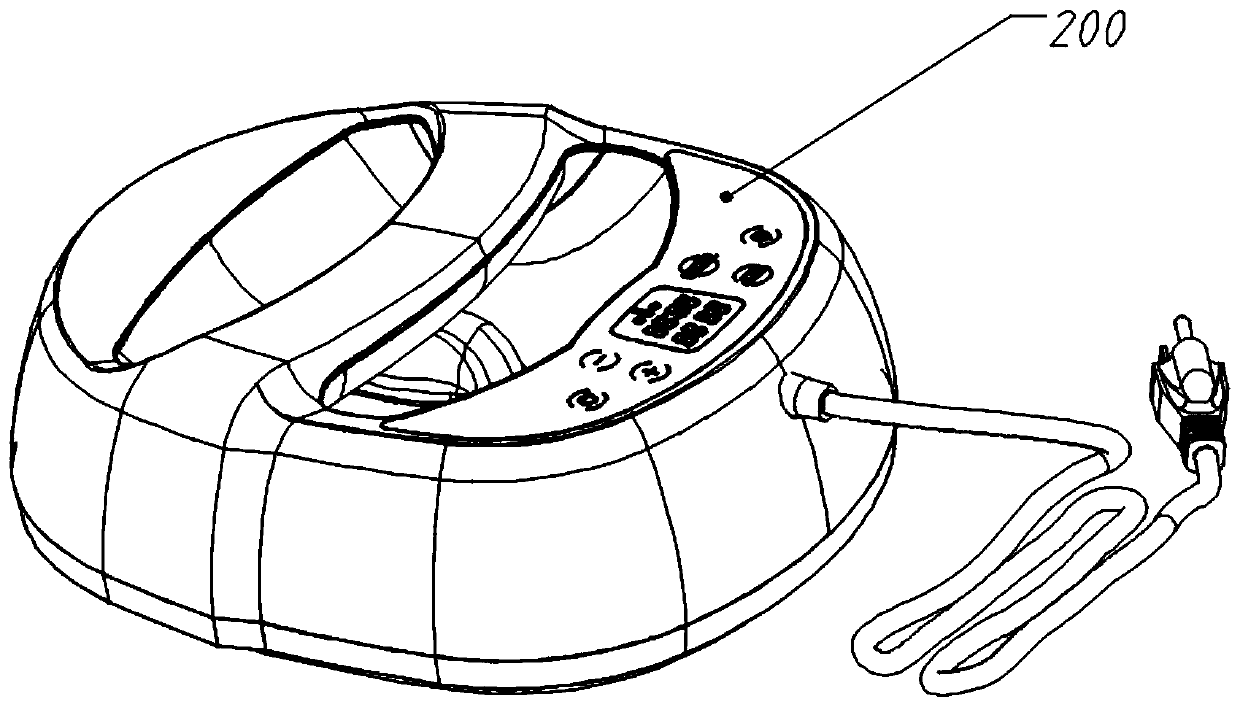

[0070] Reference attached Figure 3-8 , a pressure-free high-frequency suspension thermal transfer machine, including a host assembly 200, the host assembly 200 is provided with an outer shell 201, an inner shell 202, a secondary heat insulation shell 203, a fixed shell 204, a primary Heat insulation shell 205 and heating plate 206; a handle tray 2021 is fixed between the outer shell 201 and the inner shell 202, and a high-frequency transducer motor 406 is installed between the handle tray 2021 and the inner shell 202; a handle beam 2022 is fixed on the top of the handle tray 2021 , the handle beam 2022 is equipped with a radiator 2023, and the radiator 2023 is equipped with a control output board 403; the heating board 206 is also provided with a sudden jump temperature controller 401 and a temperature sensor 402; the rear top of the shell 201 is equipped with a central control board 404, A high-frequency switching power supply 405 is installed below the central control board...

Embodiment 2

[0101] On the basis of Embodiment 1, the host assembly 200 is also equipped with a placement tray 100, and the host assembly 200 is co-located in the placement tray 100 for placement and placement;

[0102] refer to Figure 12-16 The placement tray 100 is circular and is composed of four quarter-arc-shaped pieces 101 with end-to-end buckles; the bottom of the placement tray 100 is equipped with feet 102; the outer ring of the placement tray 100 is equipped with a limit block 103, and Suspension 104 is housed.

[0103] The placement tray adopts the same arc-shaped block structure, only need to open a small mold during production, the overall production difficulty and cost are greatly reduced, and the packaging volume is also greatly reduced during product packaging, especially in international trade. For occasions with high requirements on transportation costs, it can reduce costs and improve product competitiveness. In addition, the circular ring on which the disk is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com