Patents

Literature

34results about How to "Good noise canceling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

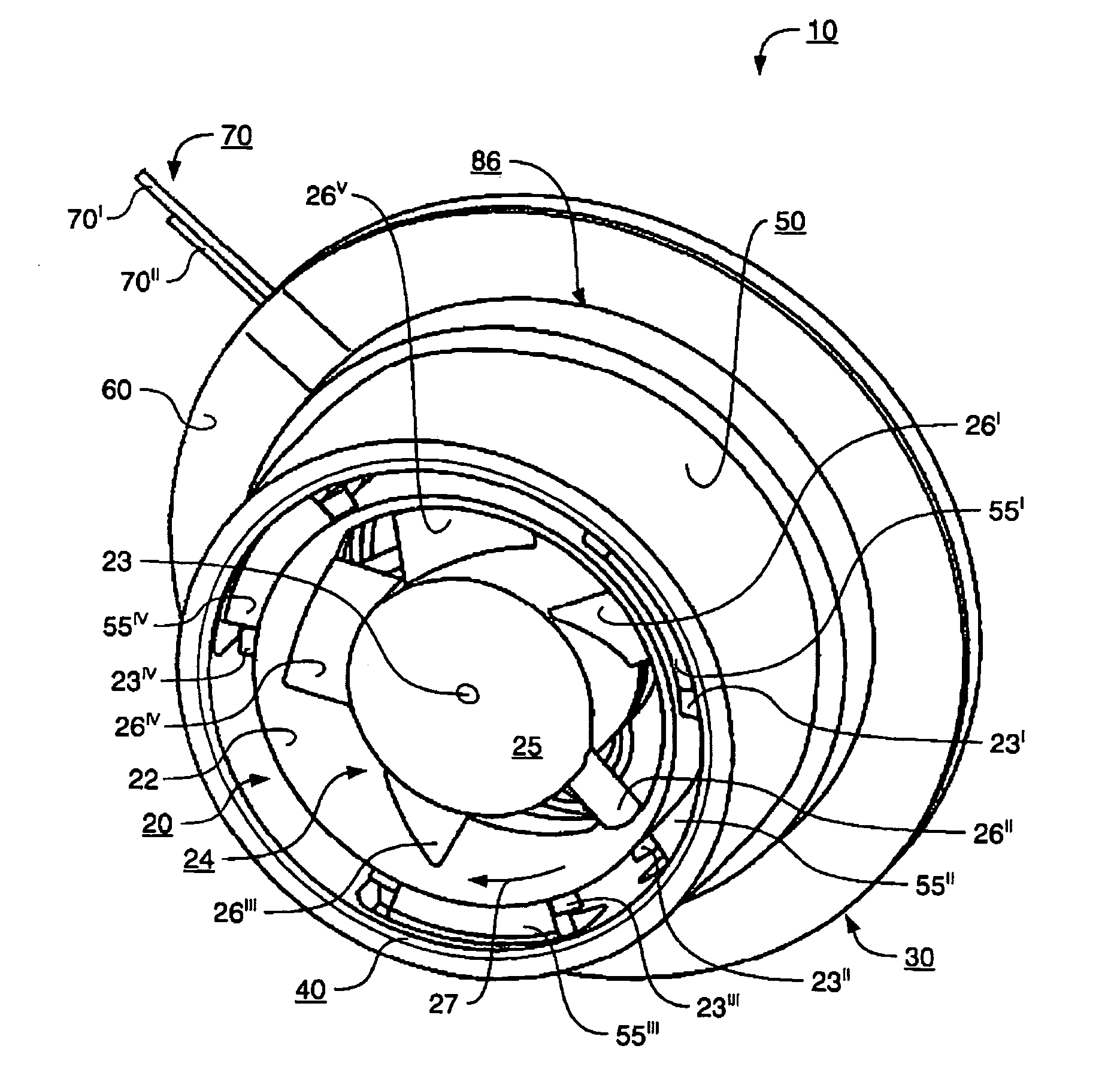

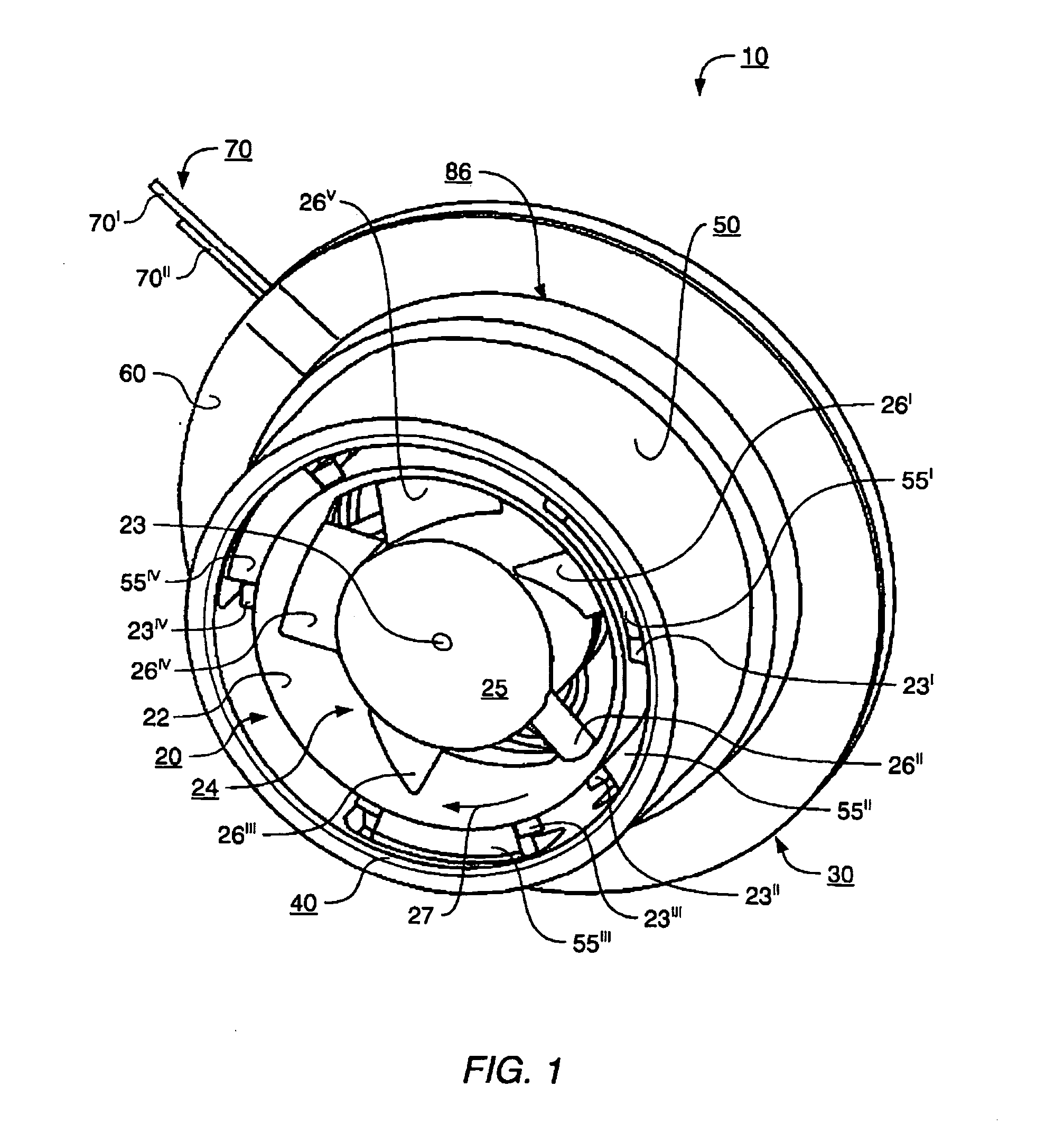

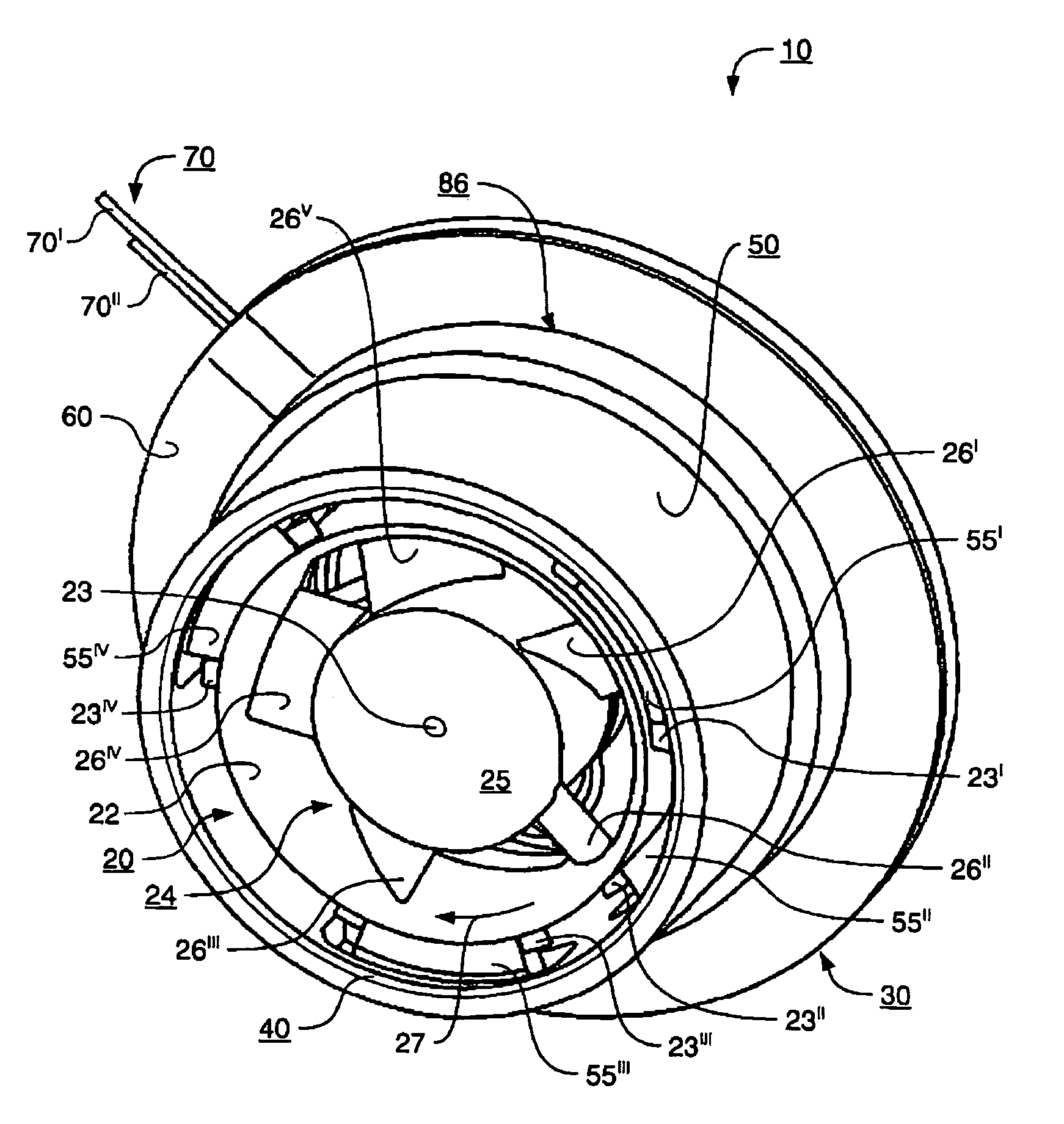

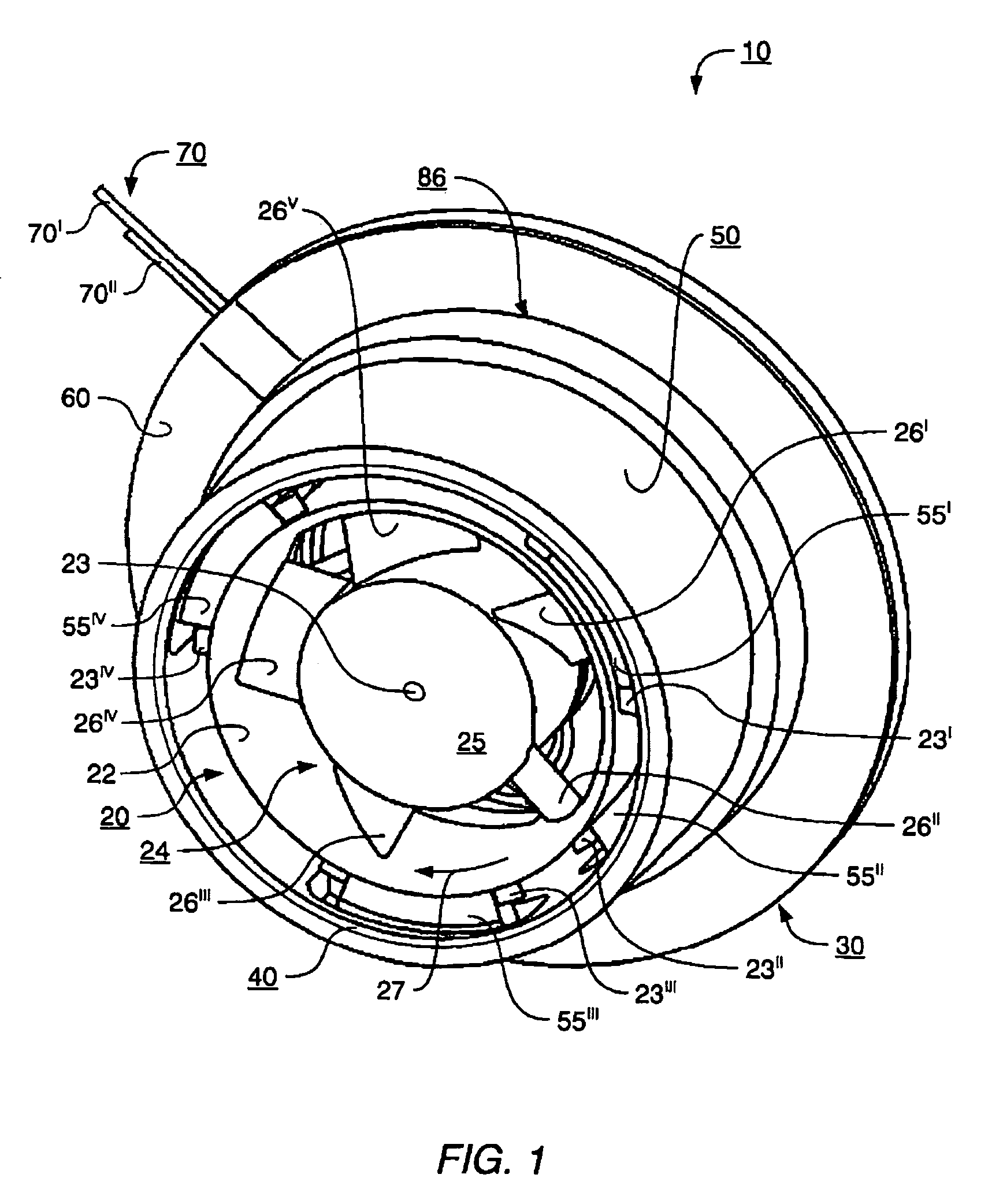

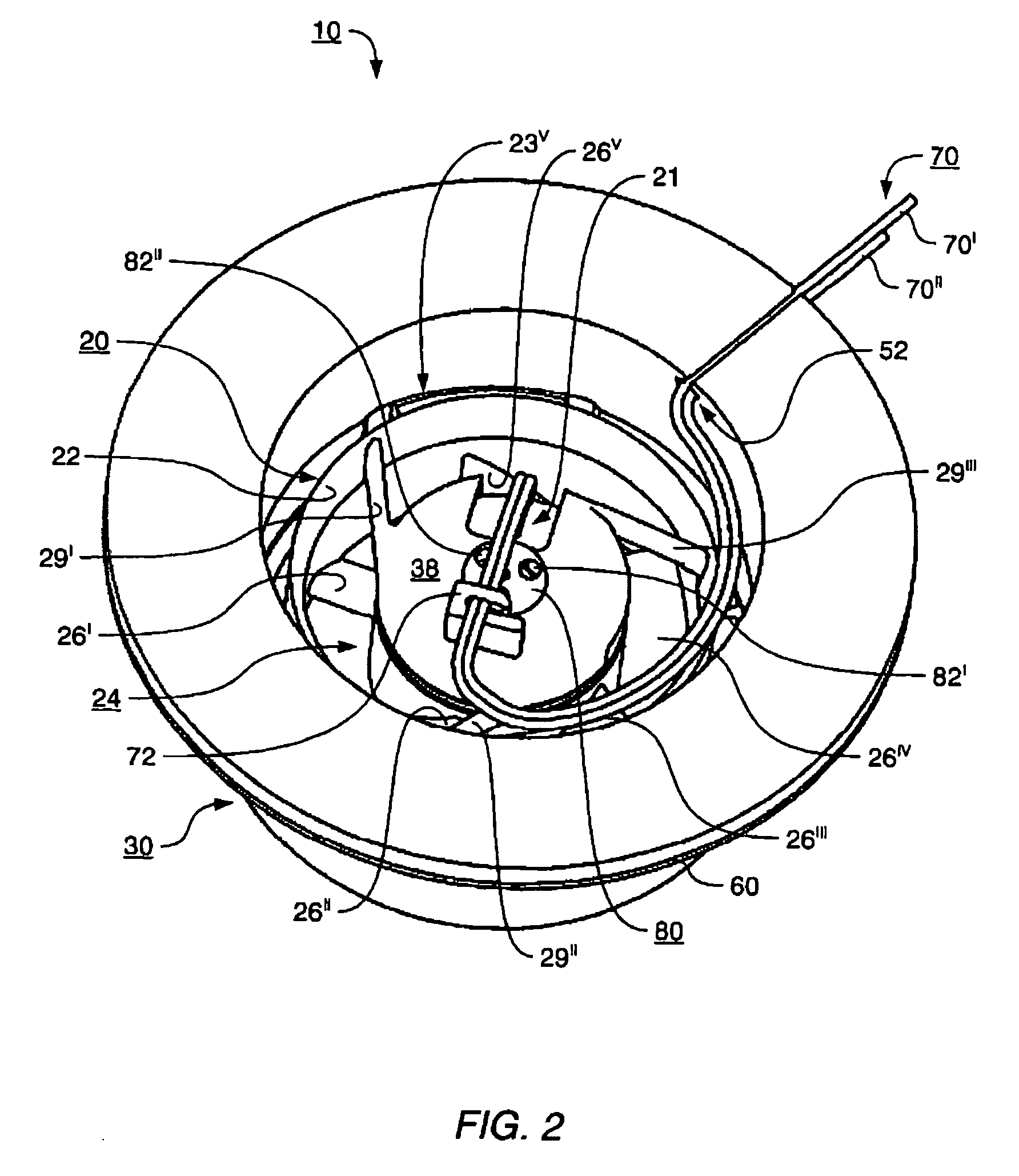

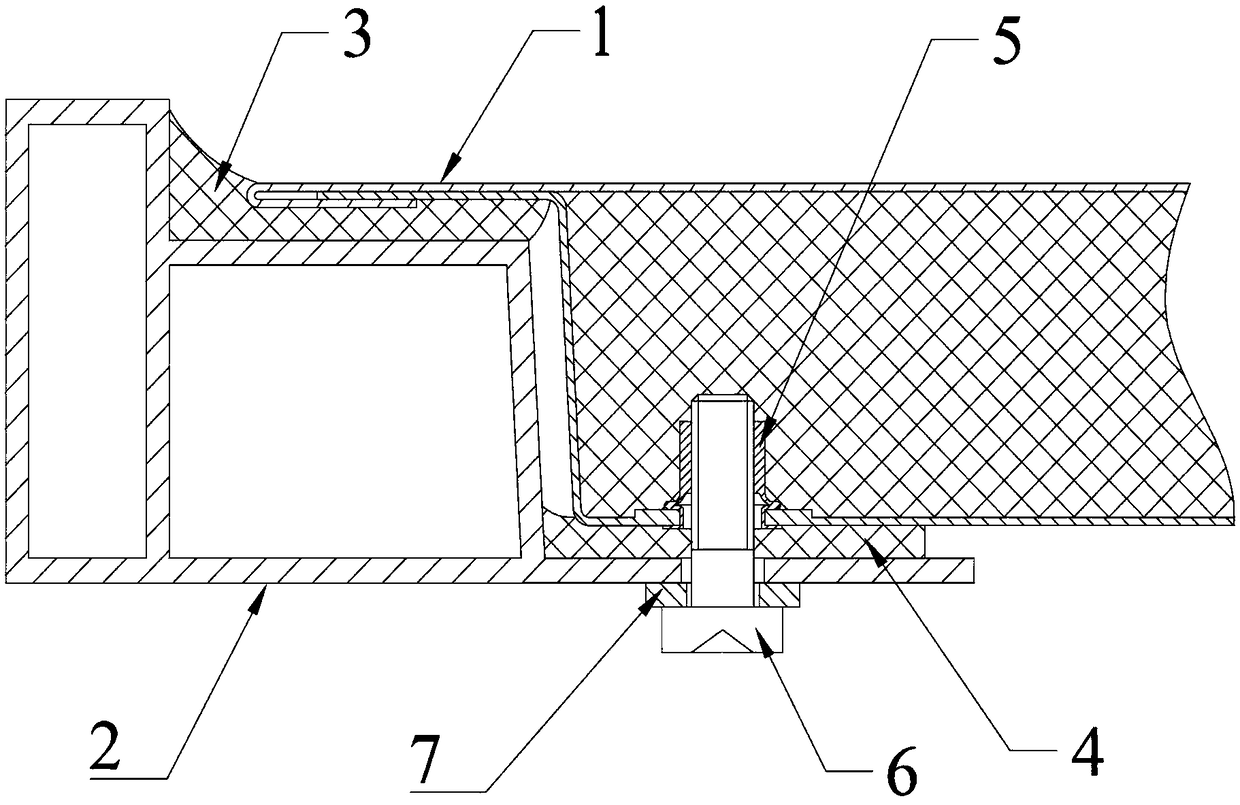

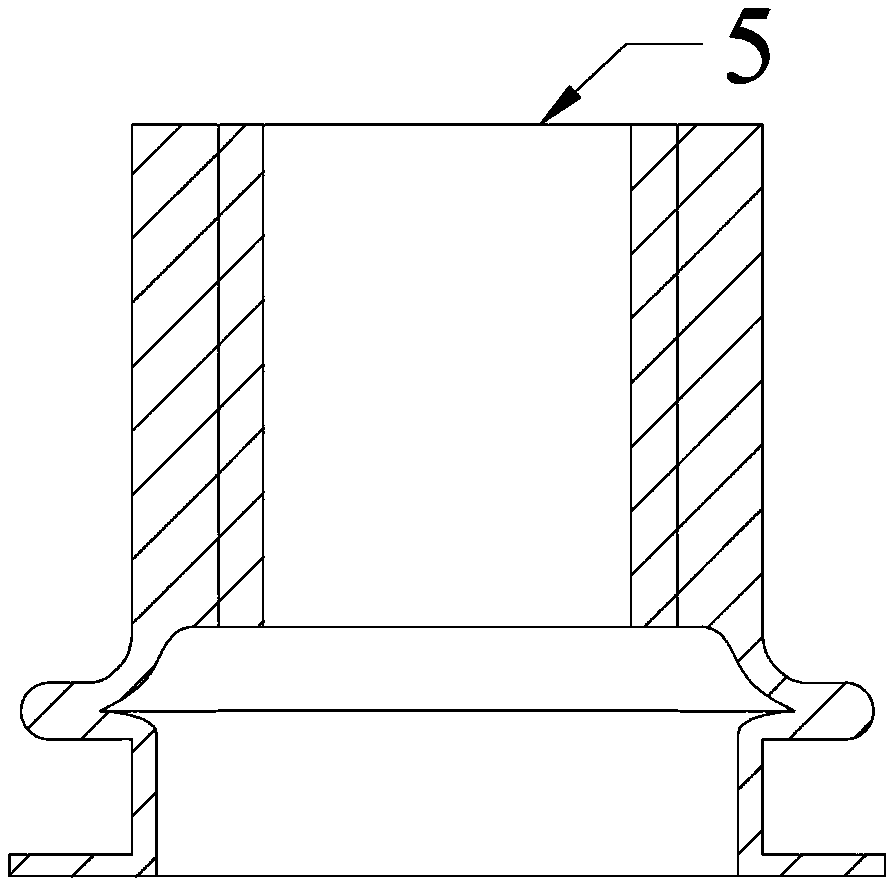

Fan unit having an axial fan with improved noise damping

ActiveUS20090191054A1Good noise cancelingCompact configurationPump componentsNon-rotating vibration suppressionMobile vehicleEngineering

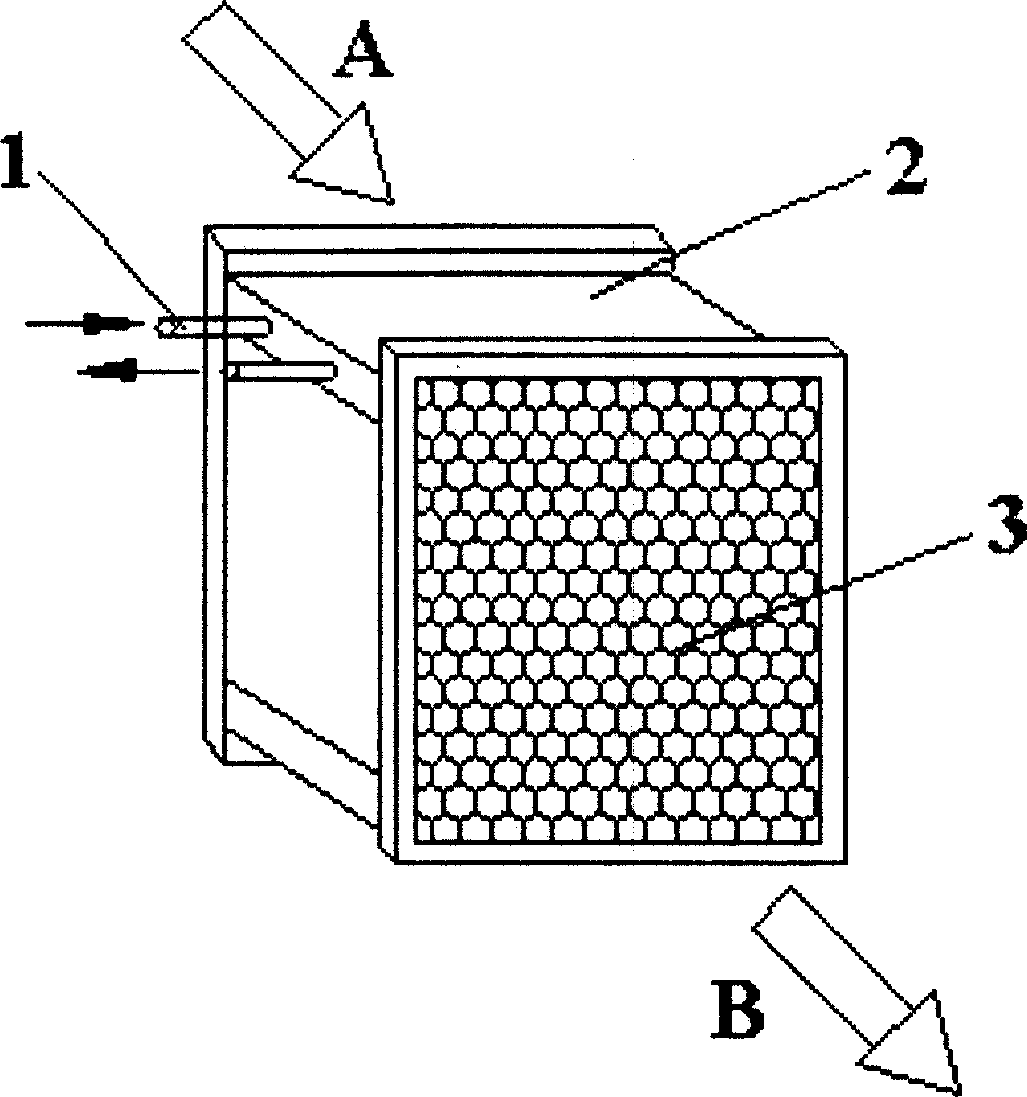

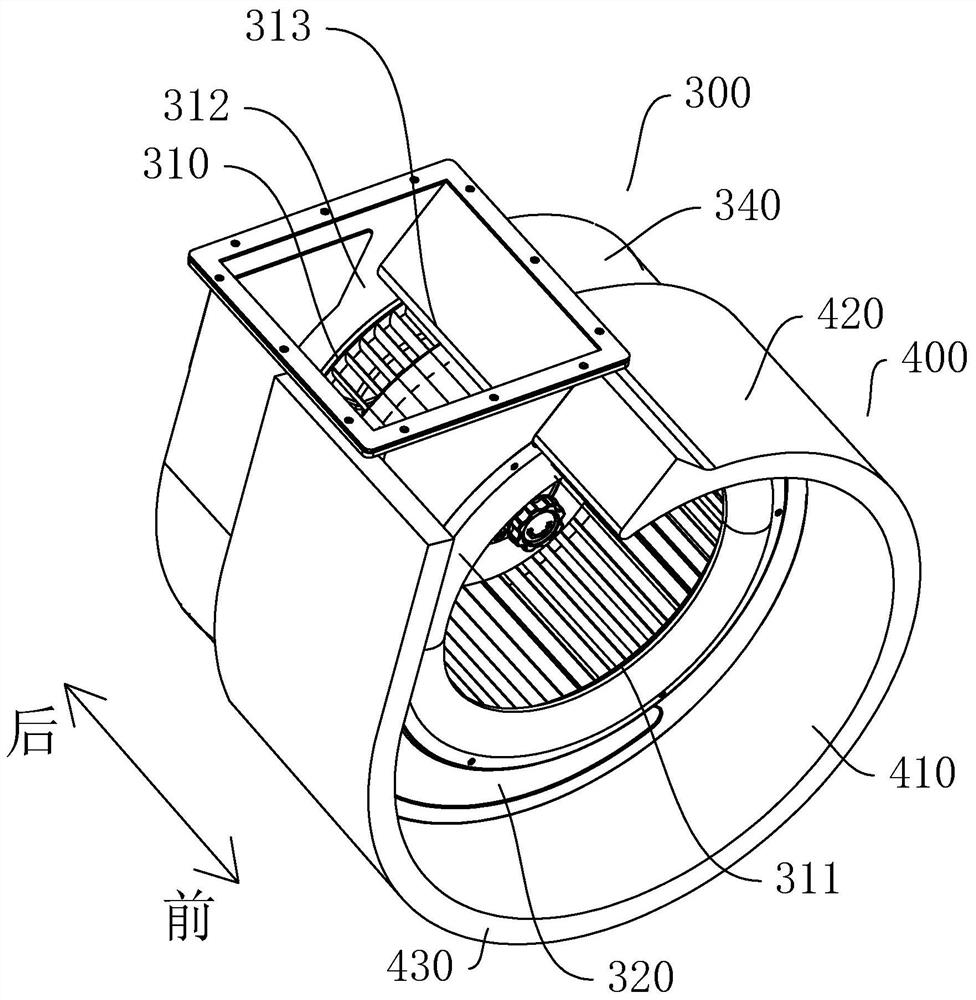

Due to variations arising during manufacturing, axial fans often are slightly imbalanced, resulting in noise during operation, which is undesirable in many contexts, for example when the fan is used for ventilation purposes in a motor vehicle. A fan with improved vibration and noise damping can be achieved by elastically suspending the fan wheel within a first ring formed of a hard plastic, the first ring having a tubular extension formed of a softer plastic, and serving to mechanically connect the first ring to a surrounding annular carrier part. Optionally, the first ring and extension unit can include a spring element. Preferably, the first ring and tubular extension are produced by a multi-component forming technology such as two-plastic technology. The fan is preferably driven by an electronically commutated motor (ECM).

Owner:EBM PAPST ST GEORGEN & -

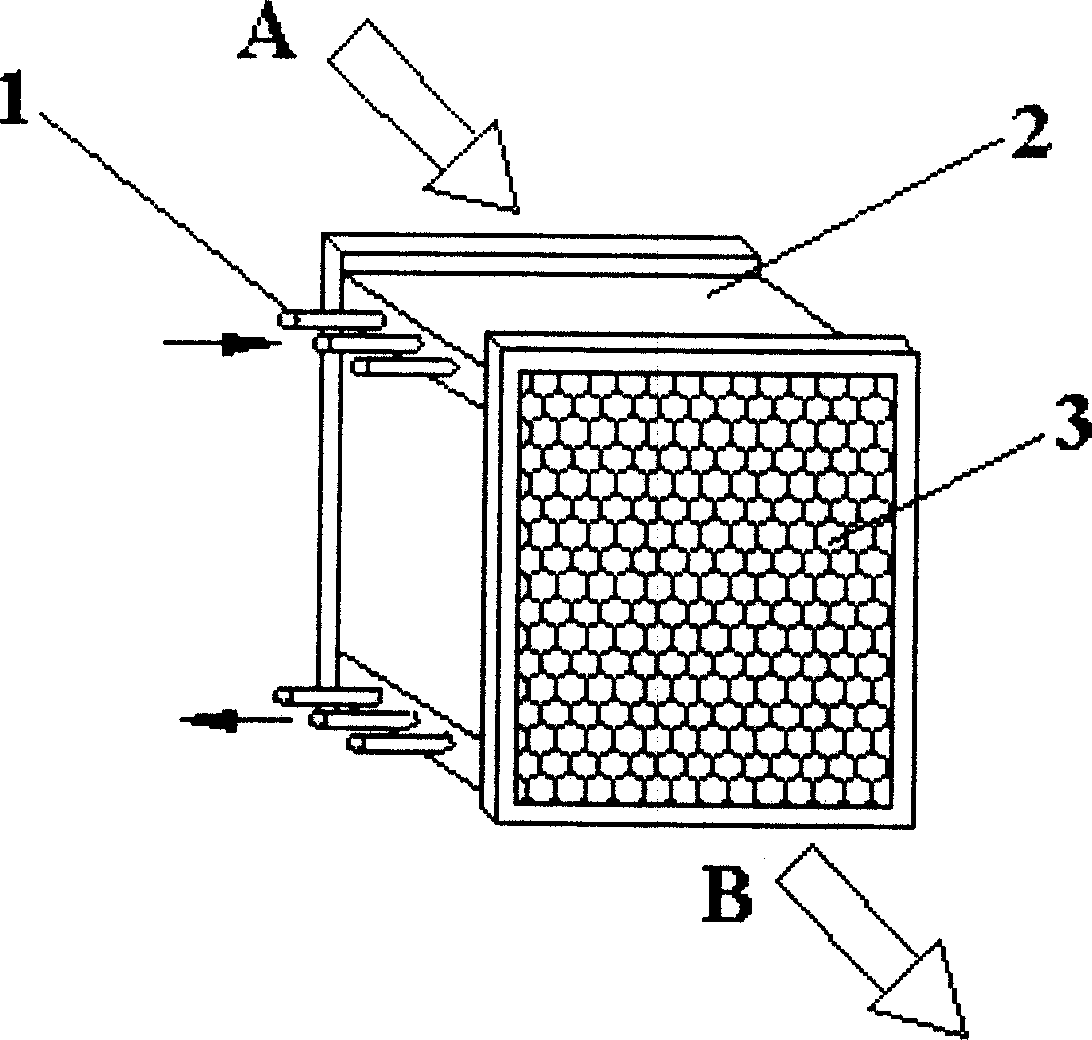

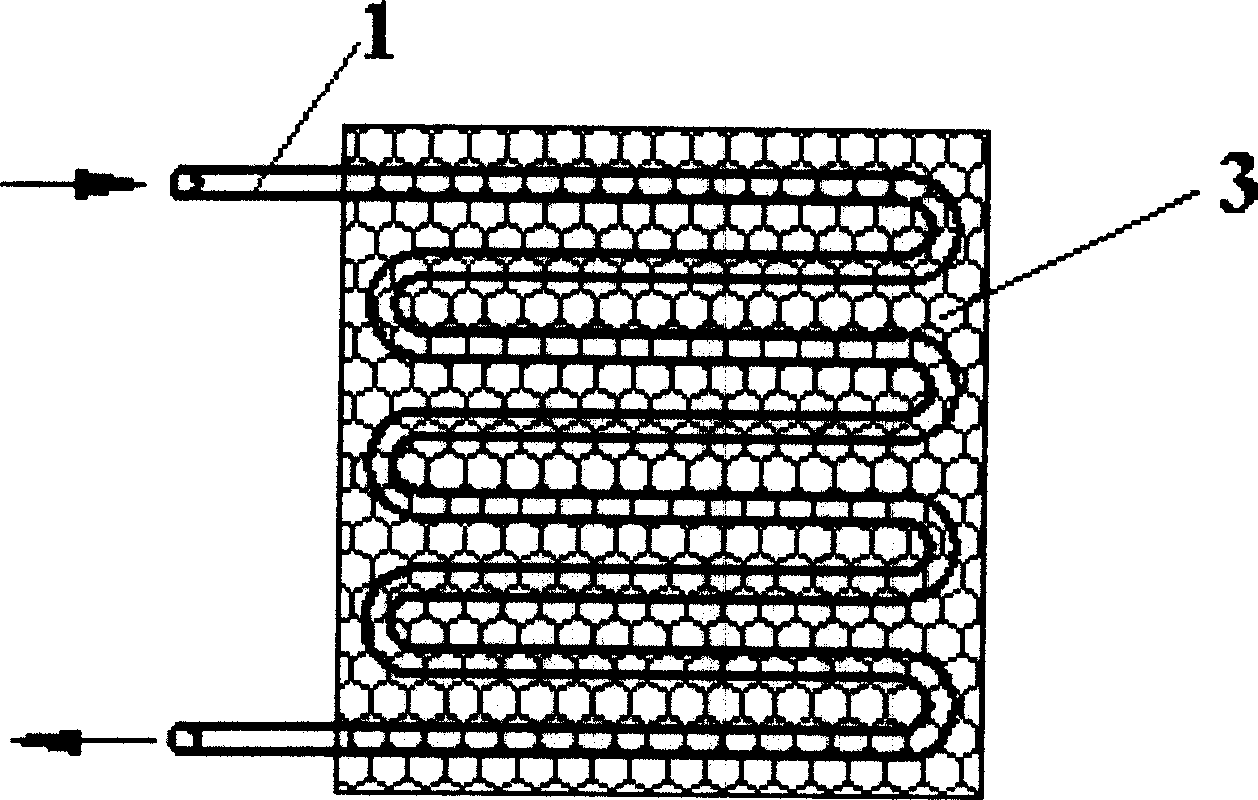

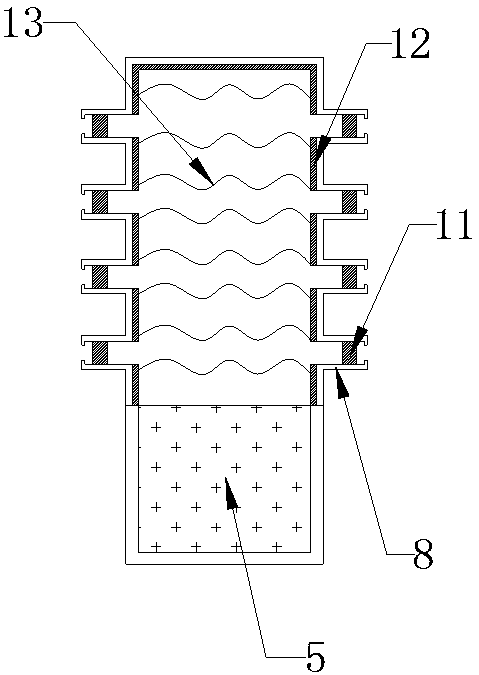

Tube type heat exchanger

InactiveCN1916550AReduce weightSmall structure sizeStationary tubular conduit assembliesHeat transfer modificationPlate heat exchangerHeat transfer efficiency

A heat exchanger of tubular type consists of heat exchange tube, heat exchange component set on external surface of said tube and auxiliary heat exchange unit for assisting heat exchange. It is featured as using metal foam as heat exchange component covered on external of said tube and forming metal foam holes at internal of metal foam to let gas or liquid pass through.

Owner:XI AN JIAOTONG UNIV

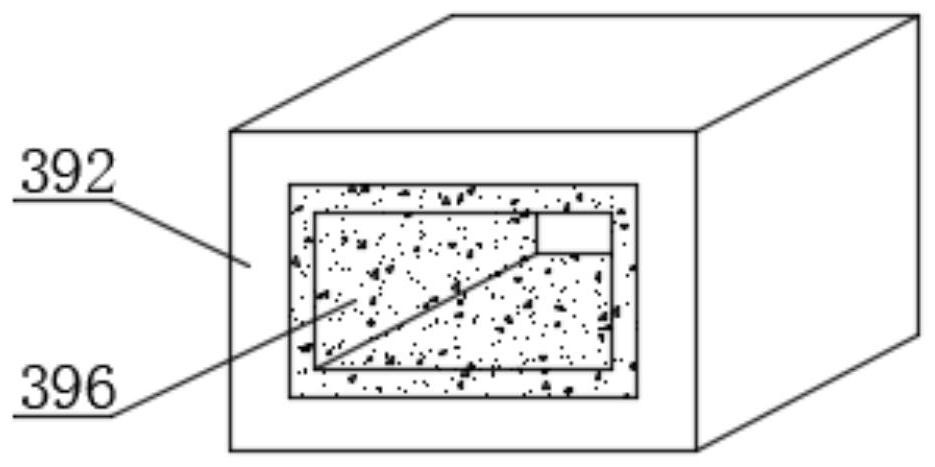

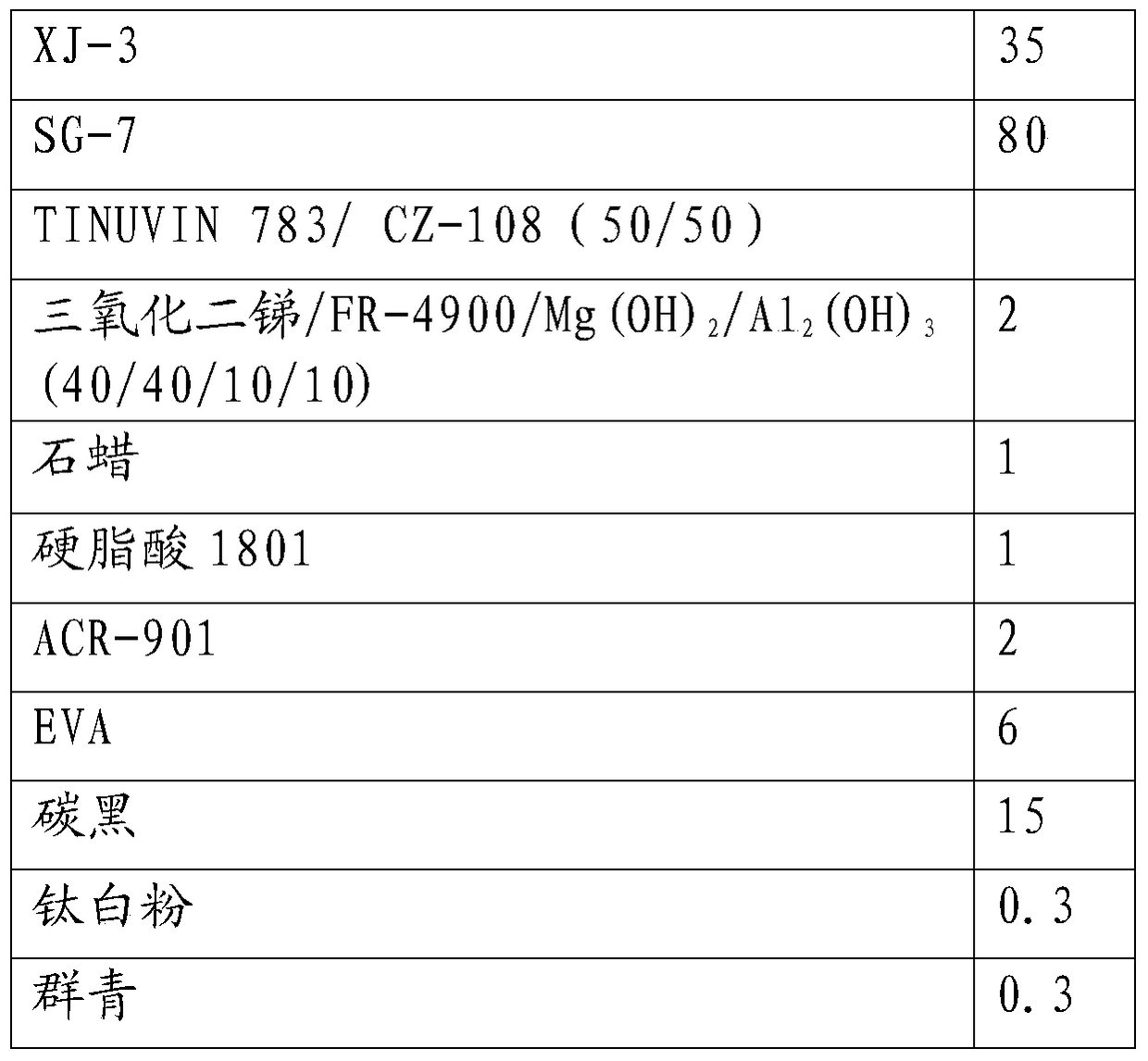

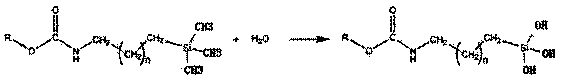

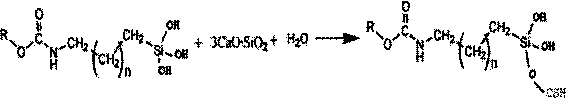

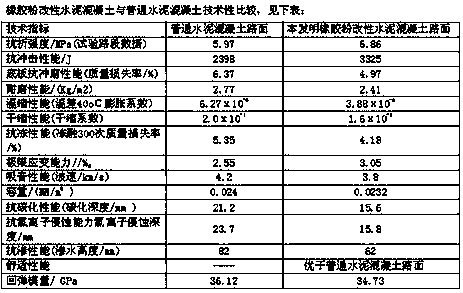

Rubber powder modified cement concrete pavement and manufacturing method thereof

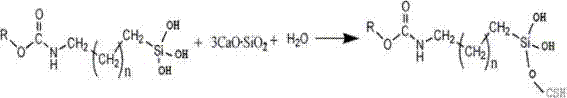

ActiveCN107188488AEffective digestionExtended service lifeIn situ pavingsSolid waste managementCelluloseWear resistant

The invention discloses a rubber powder modified cement concrete pavement and a manufacturing method thereof. The rubber powder modified cement concrete pavement is characterized by being prepared from the following raw materials in parts by weight: 25 to 30kg / m<3> of rubber powder, 300 to 330kg / m<3> of 425 cement, 550 to 590kg / m<3> of river sand, 1080 to 1180kg / m<3> of broken stone, 135 to 165kg / m<3> of water, 5 to 7kg / m<3> of water reducing agents, 3 to 4kg / m<3> of phthalic ester coupling agents, 2 to 3kg / m<3> of rubber latex, 3 to 4kg / m<3> of hydrophobic modification cellulose, 15 to 20kg / m<3> of lignin, 80 to 110kg / m<3> of granulitic blast-furnace ore slag powder and the like. The raw materials are effectively mixed to obtain the concrete. The rubber powder modified cement concrete pavement has the characteristics that the properties of anti-folding intensity, anti-impact performance, bottom plate anti-impact and anti-abrasion performance, wear-resistant performance, temperature shrinkage, dry shrinkage performance, freezing resistance performance, ultimate strain capability, noise reducing performance, volume weight, corrosion resistance and the like of the rubber powder modified cement concrete pavement are superior to those of the ordinary cement concrete pavement; the later-stage maintenance cost is lower than that of the ordinary cement concrete pavement, and the like.

Owner:广西航务建设工程有限公司

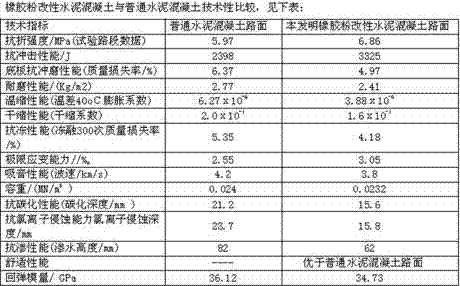

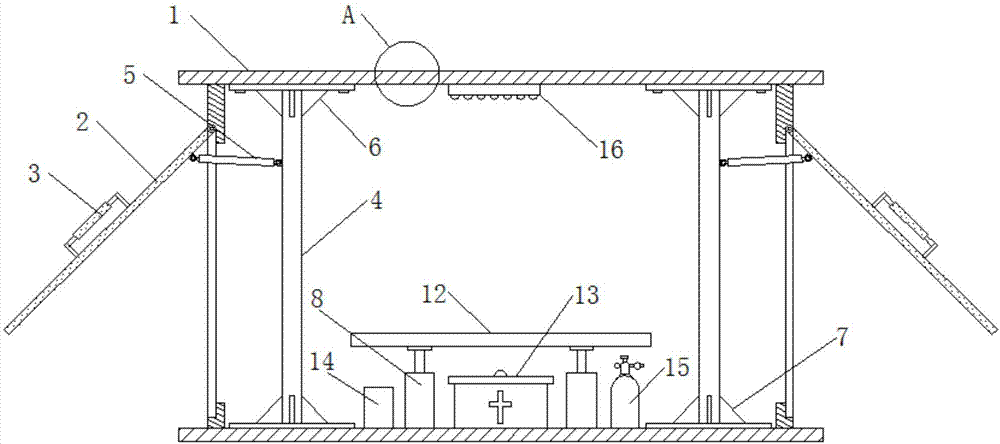

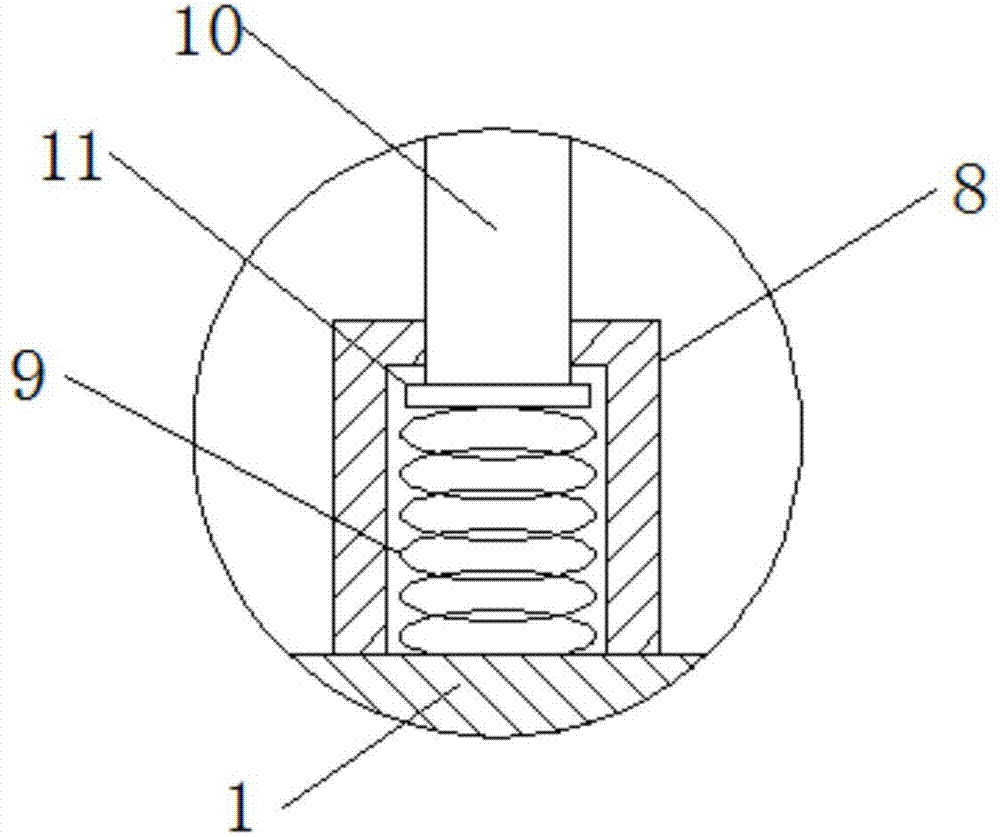

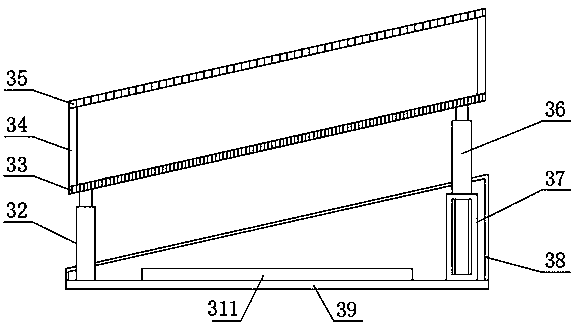

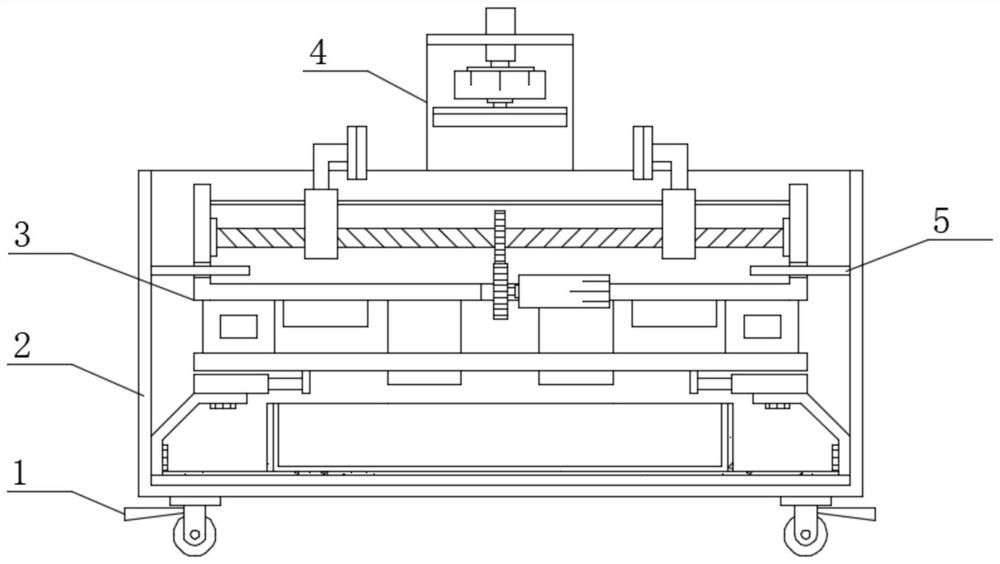

Rescue capsule for coal mining

InactiveCN107882588ANovel structureImprove usabilitySynthetic resin layered productsPower-operated mechanismHydraulic cylinderEngineering

The invention discloses a rescue cabin for coal mine development, which includes a cabin body, side doors are hinged on the left and right side walls of the cabin body, handles are connected to the side doors, and supports are longitudinally arranged inside the cabin body Beam, the top of the support beam is provided with a first reinforcement rib, the bottom end of the support beam is provided with a second reinforcement rib, a hydraulic cylinder is provided between the support beam and the side door, and the two ends of the hydraulic cylinder are respectively It is connected to the support beam and the side door through the rotation of the pin shaft. A sleeve is uniformly arranged in the middle of the bottom of the cabin, and the top of the sleeve is opened. The inside of the sleeve is provided with a spring, and the top of the spring is connected with a A guide column, the top of the guide column is fixedly connected with a bed body, a first aid box is provided at the bottom of the bed body, a battery pack is provided on the left side of the first aid box, and an oxygen cylinder is provided on the right side of the first aid box , an LED light is installed in the middle of the top of the cabin, which is suitable for widespread promotion.

Owner:成都千里之行科技有限公司

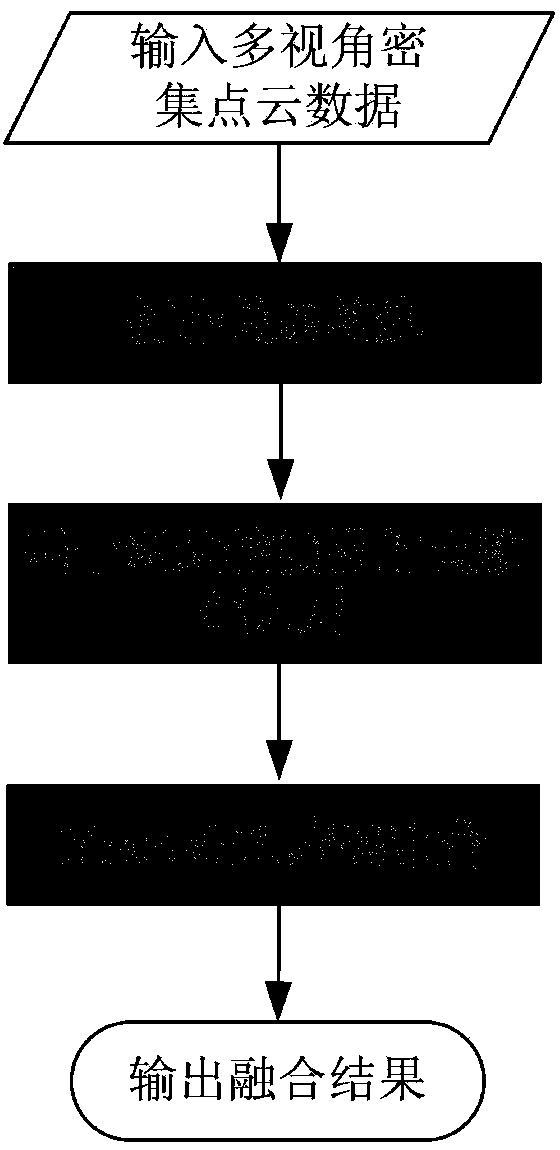

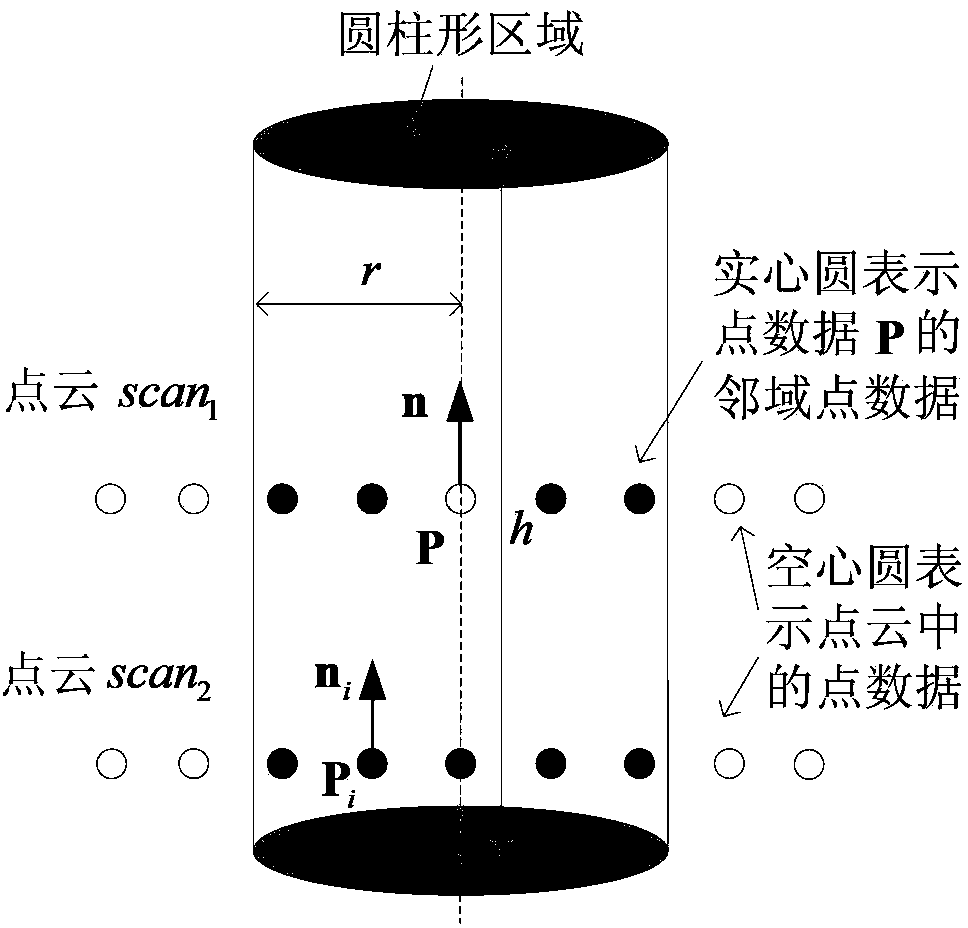

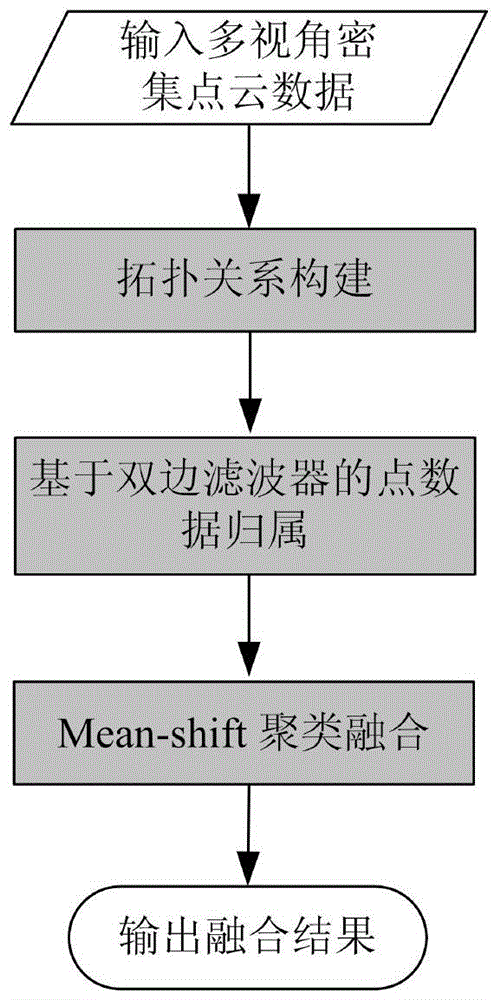

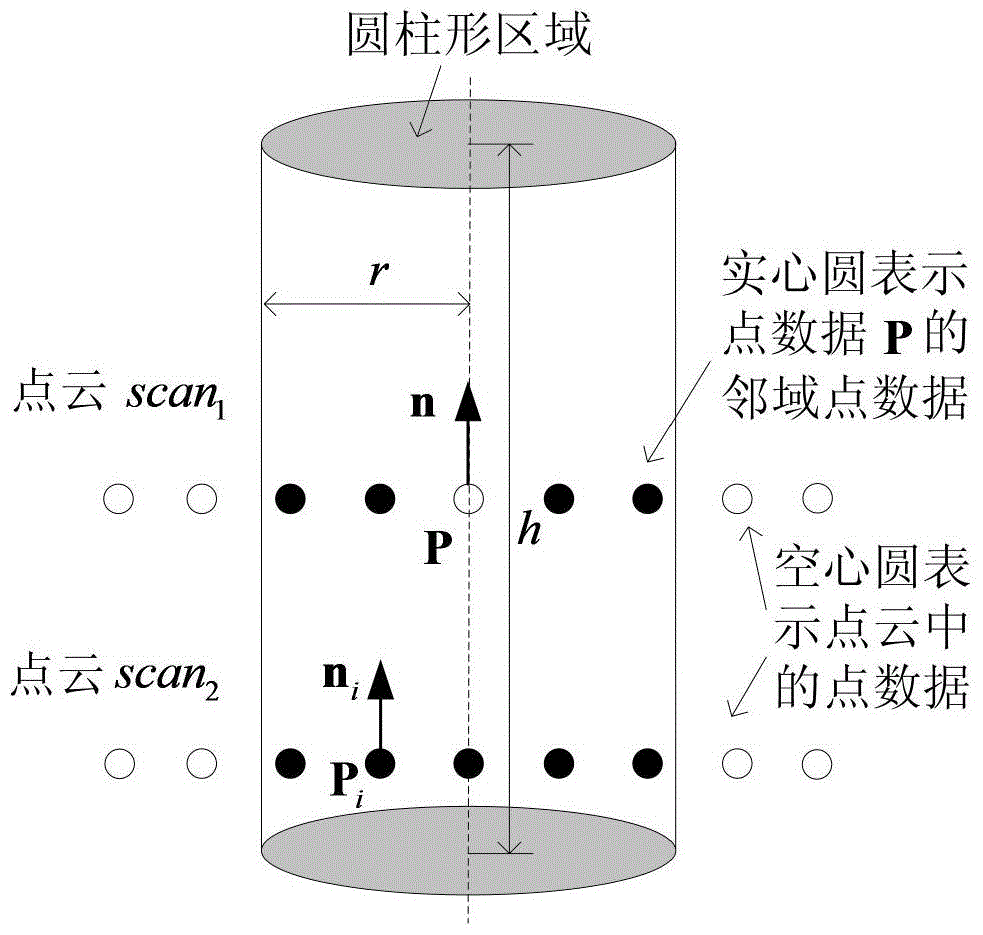

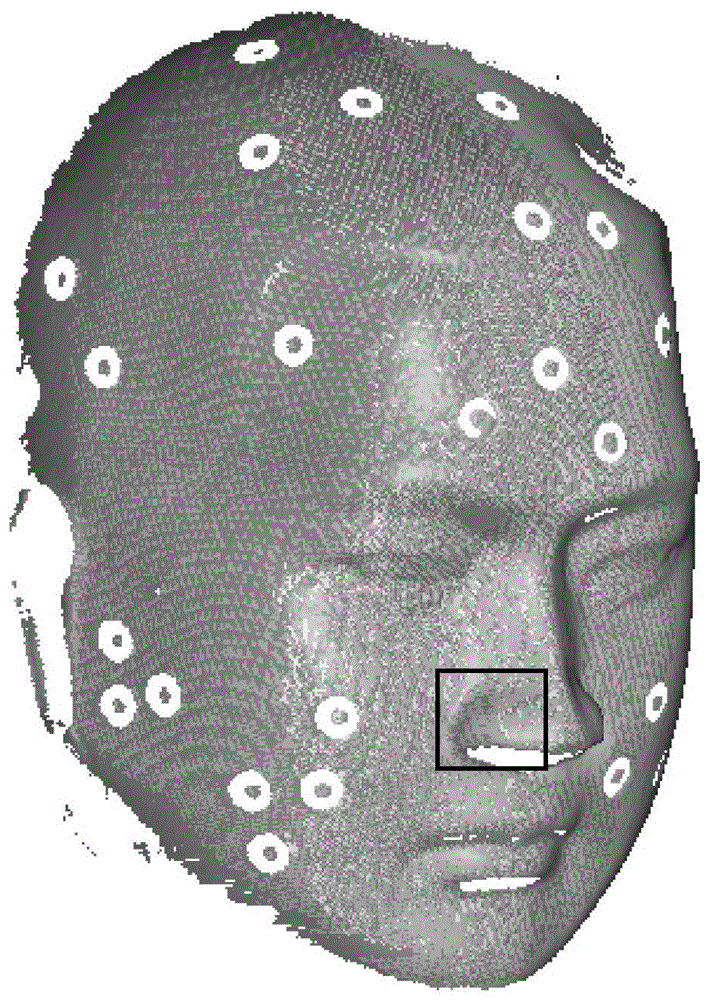

Multi-view dense point cloud data fusion method based on two-sided filter

ActiveCN104050639AImprove efficiencyGood noise cancelingImage enhancementUsing optical meansPoint cloudMean-shift

The invention discloses a multi-view dense point cloud data fusion method based on a two-sided filter and belongs to the technical field of optical three-dimensional non-contact measurement. The multi-view dense point cloud data fusion method based on the two-sided filter comprises the steps that (1) multi-view dense point cloud data are input, (2) a topological relation is established, (3) point data classification is conducted based on the two-sided filter, (4) Mean-shift clustering fusion is conducted, and (5) a fusion result is output. When the method is used for fusing the multi-view dense point cloud data, the two-sided filter and the Mean-shift clustering are introduced, recognition of an overlapping region and a non-overlapping region is not needed, in this way, the efficiency of fusing a great number of multi-view dense point cloud data is improved, the smoothness of a point cloud obtained after fusion are improved, and the defects of an existing point cloud fusion technology are effectively overcome.

Owner:XIDIAN UNIV

Drainage and noise reduction pavement construction method

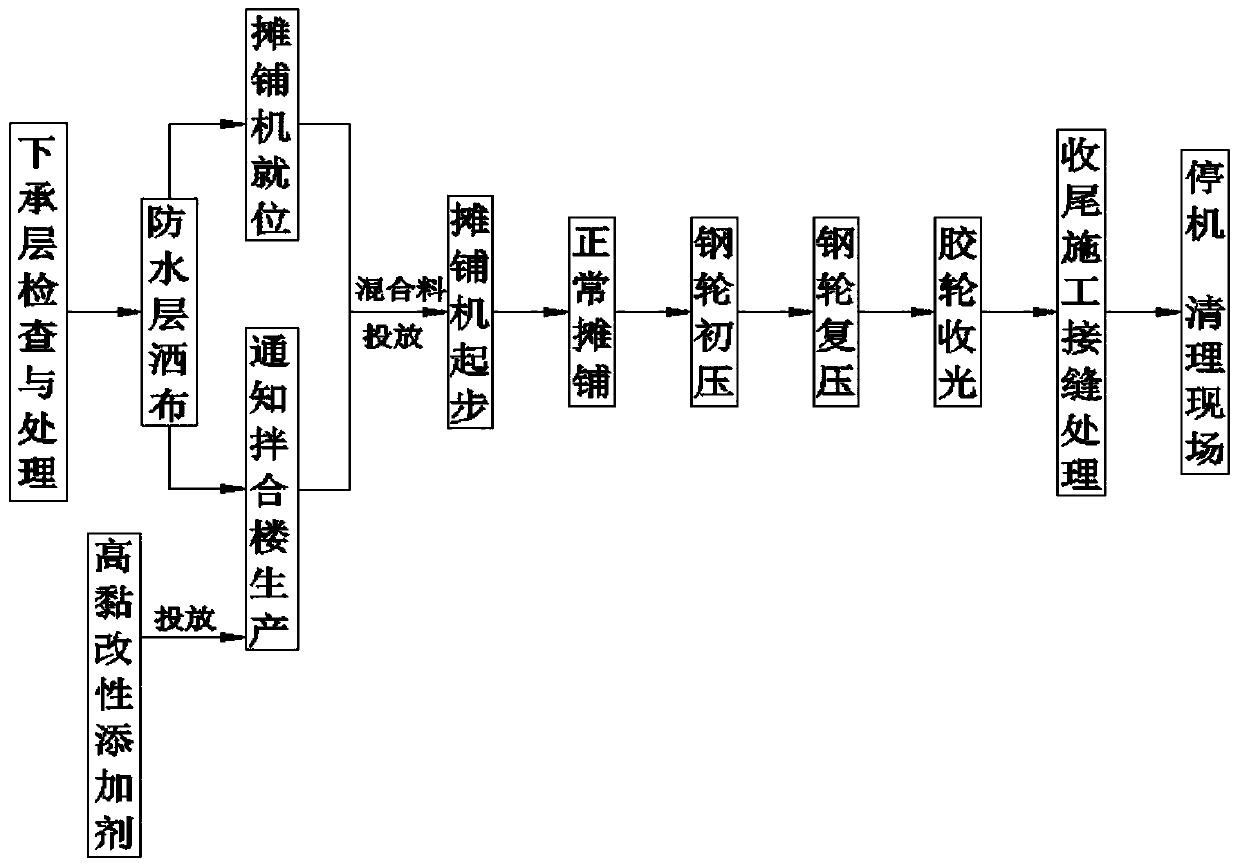

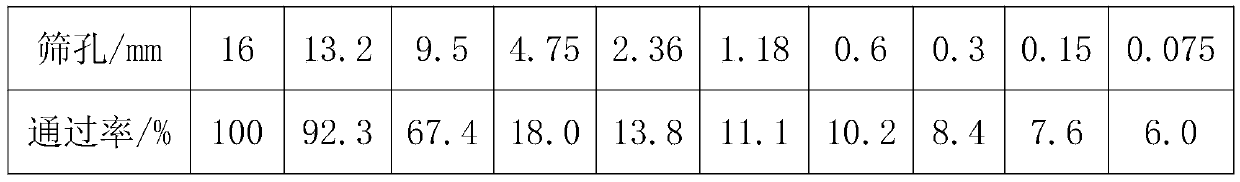

InactiveCN110409251AEasy compactionEasy aggregate crushingIn situ pavingsPaving gutters/kerbsSurface layerRoad surface

The invention discloses a drainage and noise reduction pavement construction method, and belongs to the technical field of pavement construction. The construction method includes the following steps:a step of lower bearing layer checking and processing, namely the step of performing detection and evaluation on the water seepage situations of a lower bearing layer of an asphalt pavement, and performing preliminary perfusion sealing on detected crack weak parts; a step of the distribution of a waterproof layer, namely the step of performing emulsified asphalt distribution on the surface of a middle surface layer so that a waterproof bonding layer can be formed; a step of the mixing of a drainage asphalt mixed material, namely the step of mixing the drainage asphalt mixed material through mixing equipment; a step of the transport of the drainage asphalt mixed material, namely the step of transporting the mixed drainage asphalt mixed material to a construction site; a step of the paving of the drainage asphalt mixed material, namely the step of paving the drainage asphalt mixed material on the surface of the waterproof bonding layer through a paving machine; and a step of the compaction of the drainage asphalt mixed material, namely the step of compacting the paved drainage asphalt mixed material so that a drainage asphalt upper surface layer can be formed. Therefore, the problemsof poor noise reduction and drainage effects of existing pavements can be solved.

Owner:湖南交通国际经济工程合作有限公司

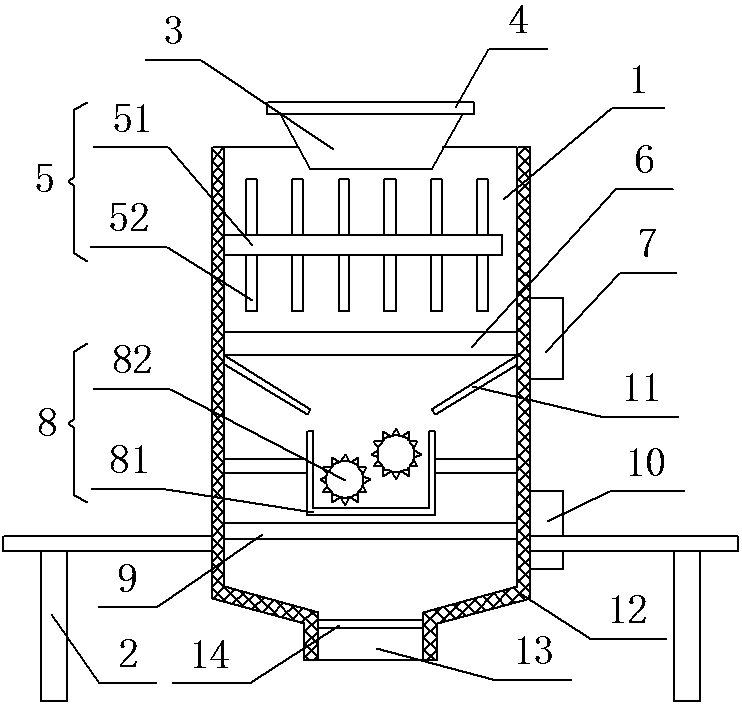

Environmentally friendly ceramic raw material crushing device

InactiveCN109692747ASame sizeImprove production environmentGrain treatmentsEngineeringNoise reduction

The invention discloses an environmentally friendly ceramic raw material crushing device. The device includes a crushing barrel and a supporting frame. The crushing barrel is located on the supportingframe. The top of the crushing barrel is provided with a charging opening. A cover matching the charging opening is arranged at the charging opening. A first-stage crushing device is arranged in theupper part of the crushing barrel. A vibrating screen plate is arranged under the first-stage crushing device. The vibrating screen plate is located at the middle part of the crushing barrel. A second-stage crushing device is arranged in the bottom part of the crushing barrel. A swinging screen plate is arranged on the bottom of the second-stage crushing device. An annular baffle plate is arrangedbetween the second-stage crushing device and the vibrating screen plate. The baffle plate is inwardly inclined and is of a funnel shape with large top and small bottom. The upper edge of the baffle plate is fixedly connected to the inner wall of the crushing barrel. The wall of the crushing barrel is of a double-layer structure. The space between the two layers of walls of the crushing barrel isfilled with noise reducing cotton. The bottom of the crushing barrel is provided with a discharging opening. According to the invention, multiple crushing can be carried out in the same device, and the environmentally friendly ceramic raw material crushing device has a good crushing effect and a good noise reduction function and effectively improves the production environment of workers.

Owner:张元龙

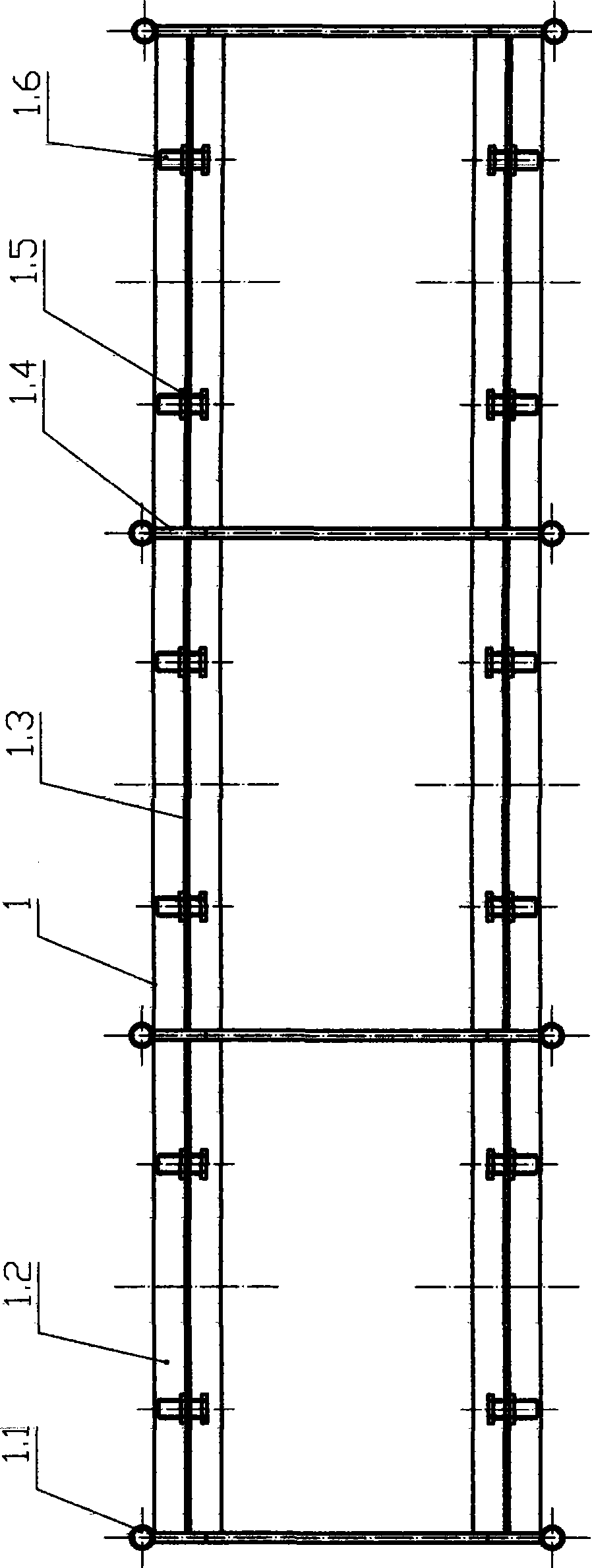

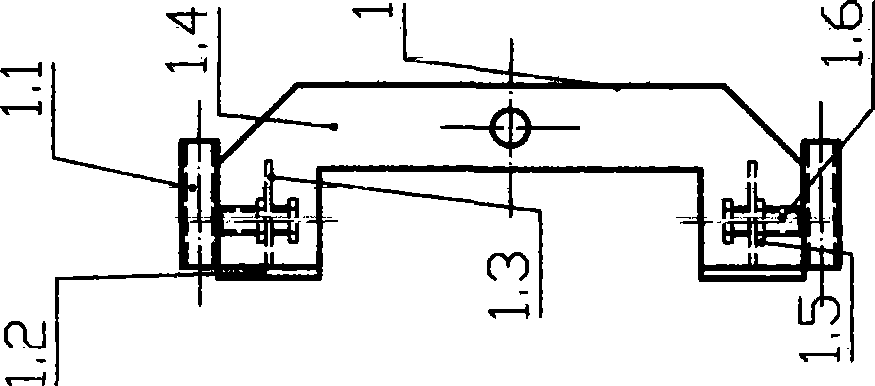

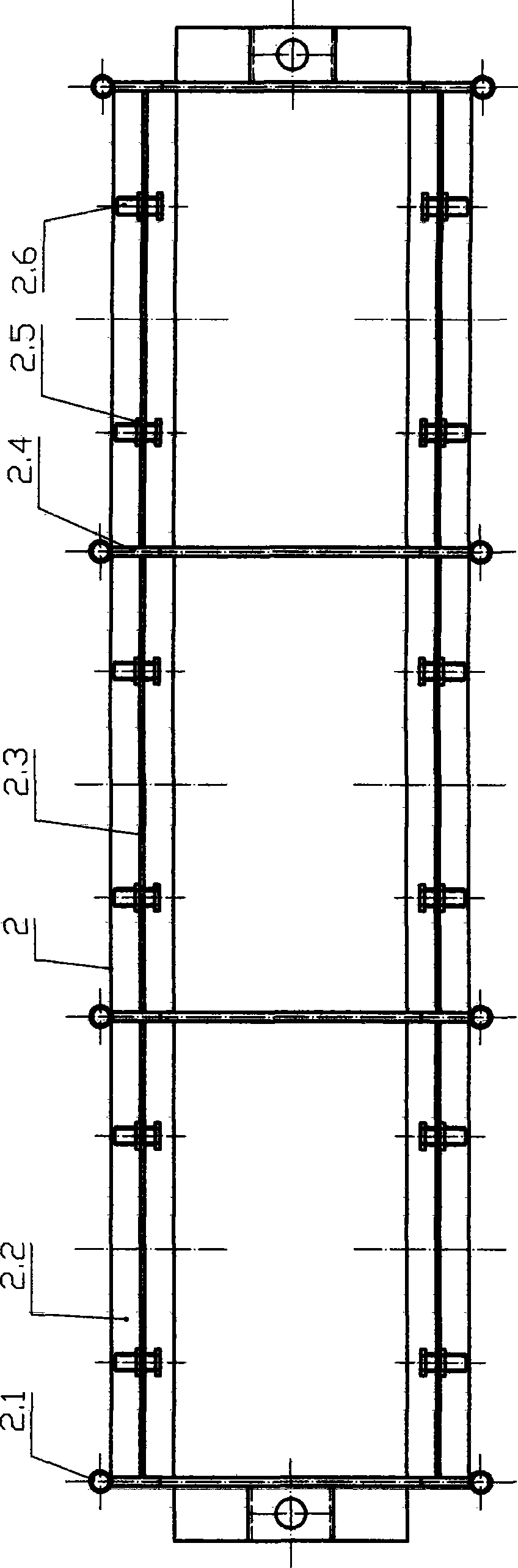

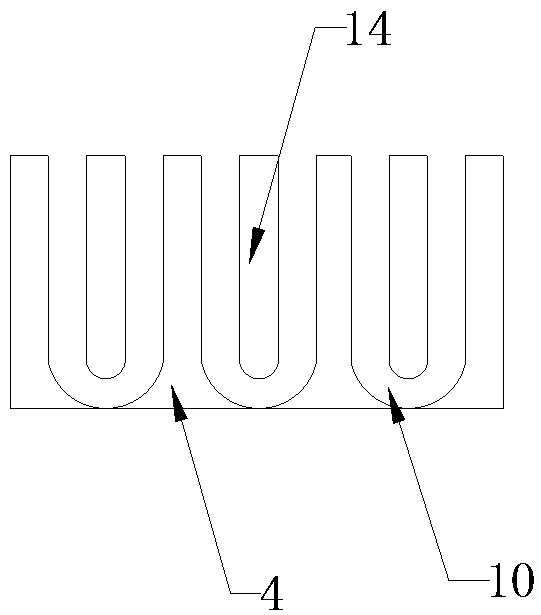

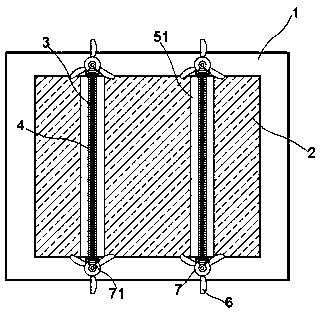

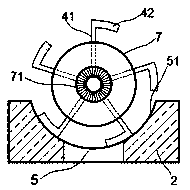

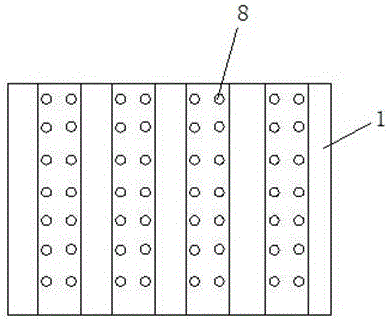

Electric transformer winding and iron core fixing device

InactiveCN101477877AClamp evenlyImprove no-load performanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresArray data structureEconomic benefits

A device for fixing a power transformer winding and an iron core consists of an upper fixture and a lower fixture with same structures. Through the reasonable regulation of arrays of screw-thread components, the uniform and effective clamping of an iron yoke is ensured, thereby overcoming the drawbacks that the stress of the iron yoke with a channel iron and teartape structure is not uniform, and the teartape is almost nonexistent; the effective cross section of the iron yoke with a core-passing screw rod structure becomes smaller, and the magnetic flux distorts; the noise is big; and the no-load capacity is reduced. The device have the advantages of reasonable design, simple structure, no-load property improvement due to timely adjustment of the clamping force of the iron yoke, obvious noise reduction function, convenient manufacture and regulation, good adaptability, high spread and application values, and remarkable socio-economic benefits.

Owner:常德国力变压器有限公司

Ecotype road surface for sponge city

InactiveCN108842546AAchieve purificationQuick rowFatty/oily/floating substances removal devicesIn situ pavingsWater storage tankRoad surface

The invention discloses an ecotype road surface for a sponge city. The ecotype road surface comprises a water permeable self-cleaning road surface and a sinking type ecological purifying belt, the sinking type ecological purifying belt is located on one side or two sides of the water permeable self-cleaning road surface, the water permeable self-cleaning road surface and the sinking type ecological purifying belt are separated by a kerb, the water permeable self-cleaning road surface comprises a roadbed, a subbottom layer, a drainage base layer and a self-cleaning surface layer from bottom totop, and the sinking type ecological purifying belt comprises a water storage layer, an initial rainwater filtering layer and a water storage tank. The ecotype road surface has the beneficial effectsthat the initial rainwater pollution of the city road is eliminated, the structure of the road surface is stable, the scope of application is wide, meanwhile, the urban inland inundation is alleviated, the water is conserved, the air humidity is regulated, the flying dust is reduced, and the air quality is improved.

Owner:福建闽泰交通工程有限公司

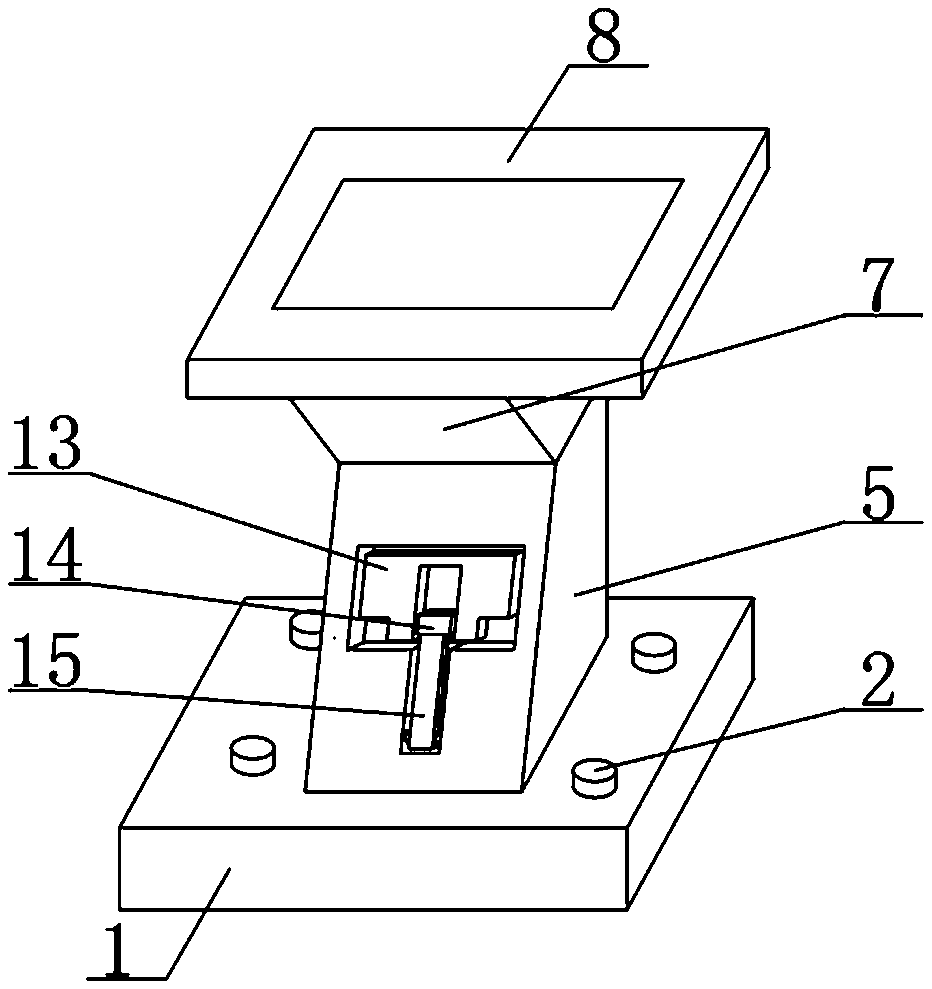

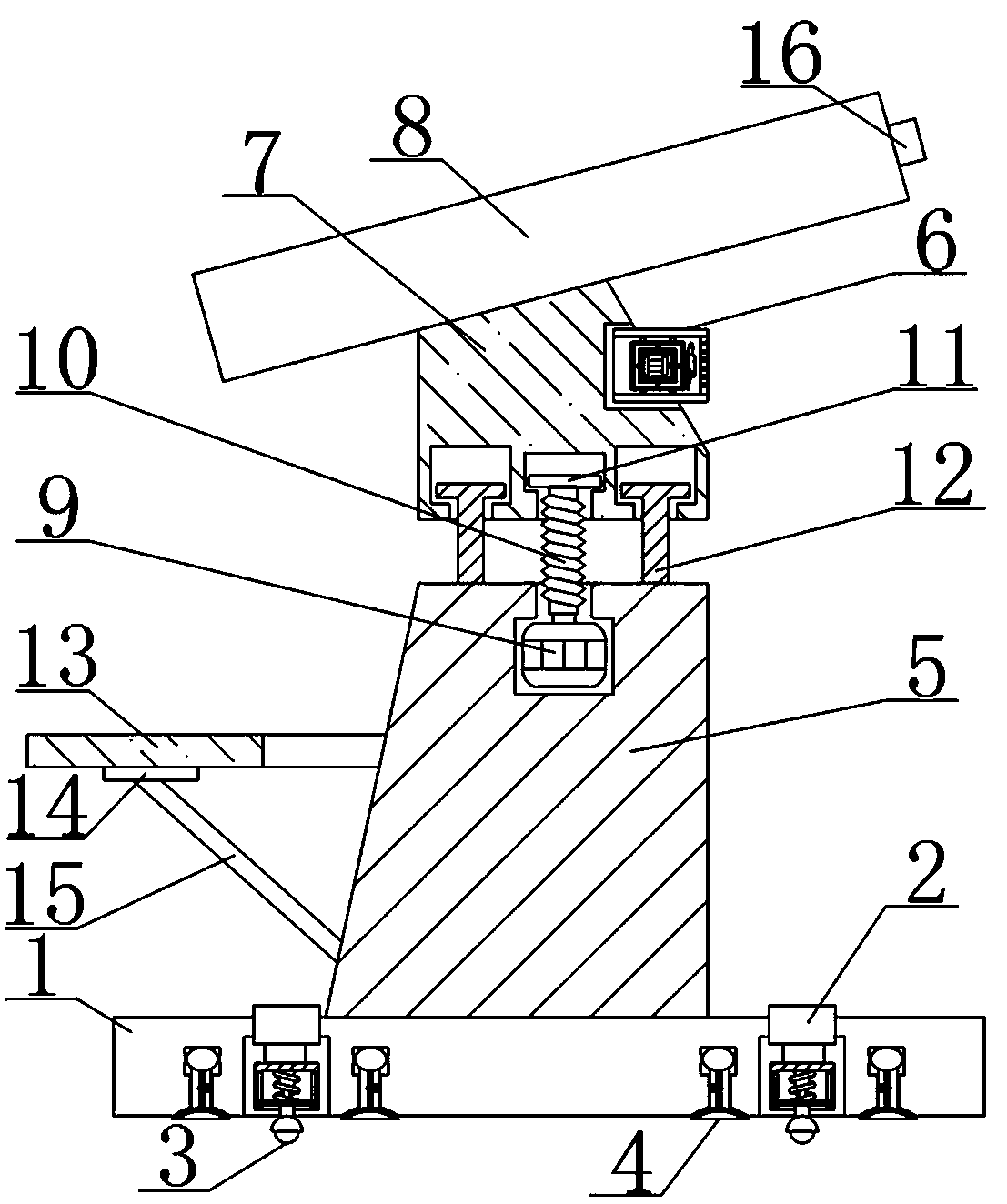

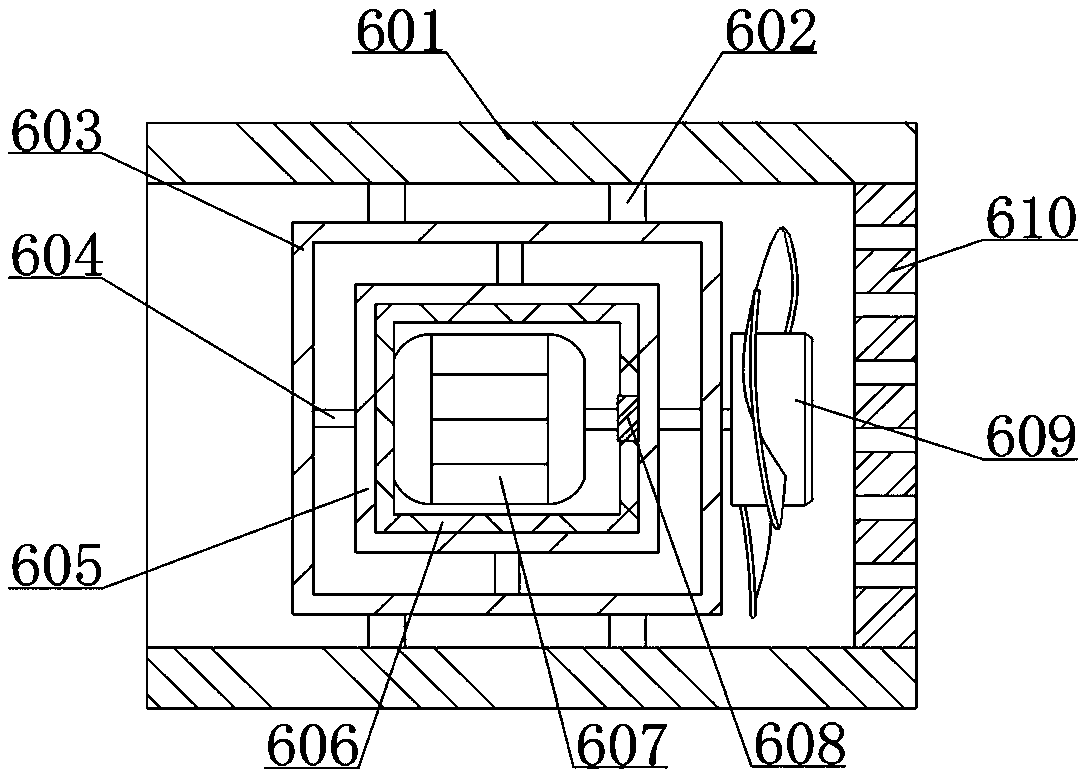

Integrated service platform for agriculture, countryside and farmers based on dual network interconnection and use method thereof

PendingCN109717613AEasy to moveImprove cleanlinessOffice tablesDigital data processing detailsComposite servicesDual network

The invention relates to the technical field of agricultural service equipment, in particular to an integrated service platform for agriculture, countryside and farmers based on dual network interconnection and a use method thereof. The platform includes a base, a lower unit shell, an upper unit shell and a display platform. Hydraulic rods are uniformly distributed and embedded in the upper end face of the base, the lower end faces of the hydraulic rods are fixedly connected with moving devices, a fixation device is embedded into the base, the upper end face of the base is fixedly connected with the lower unit shell, the front end face of the lower unit shell is rotatably connected with a rotation plate, the upper end face of the rotation plate is rotatably connected with a sliding block,the rear end face of the sliding block is slidably connected with a seat, and the rear end face of the seat is combined with the lower unit shell through clamping. Through the arrangement of a liftingmotor, a limiting plate and a limiting rod, the use range is expanded, the comfort level of people is improved when people experience the platform, the platform is convenient to move and has a good fixation function, the work efficiency can be effectively improved, and the platform has good practicability and benefits and is worth application and popularization.

Owner:祥云泰兴农业科技开发有限责任公司

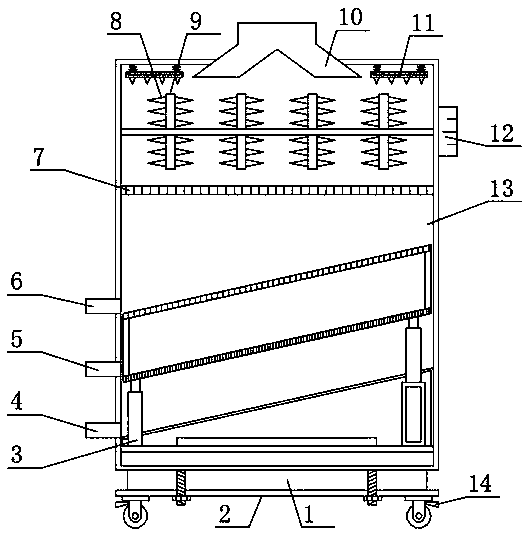

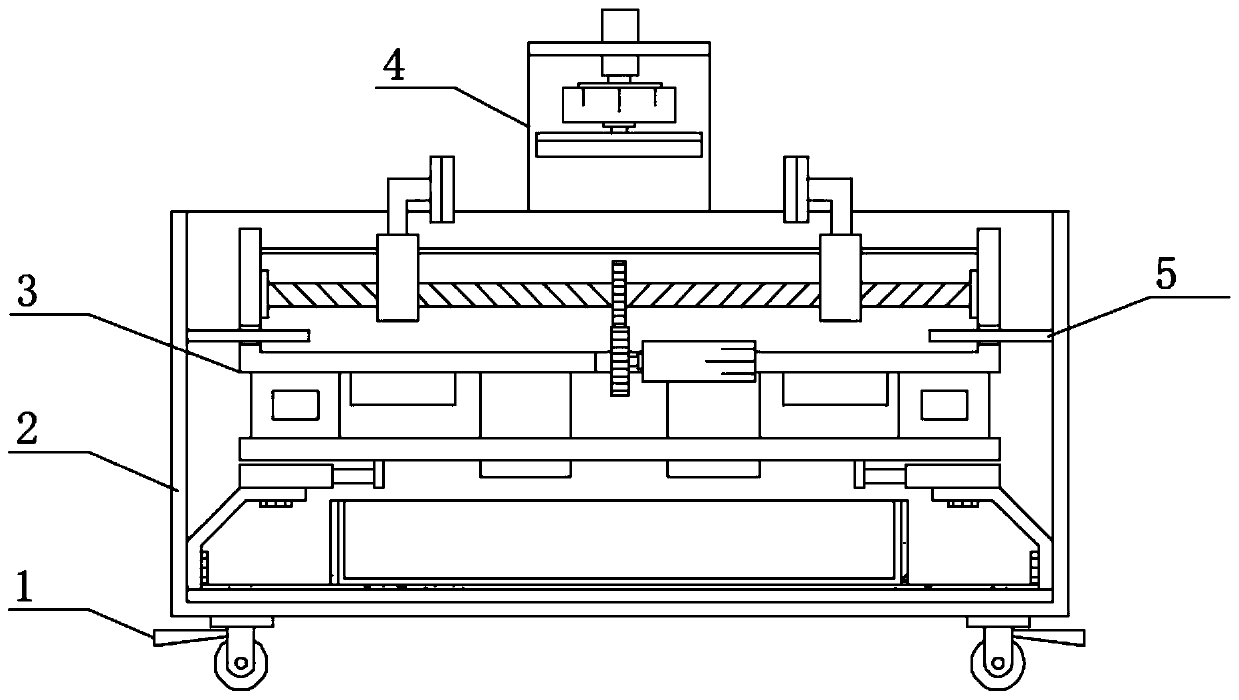

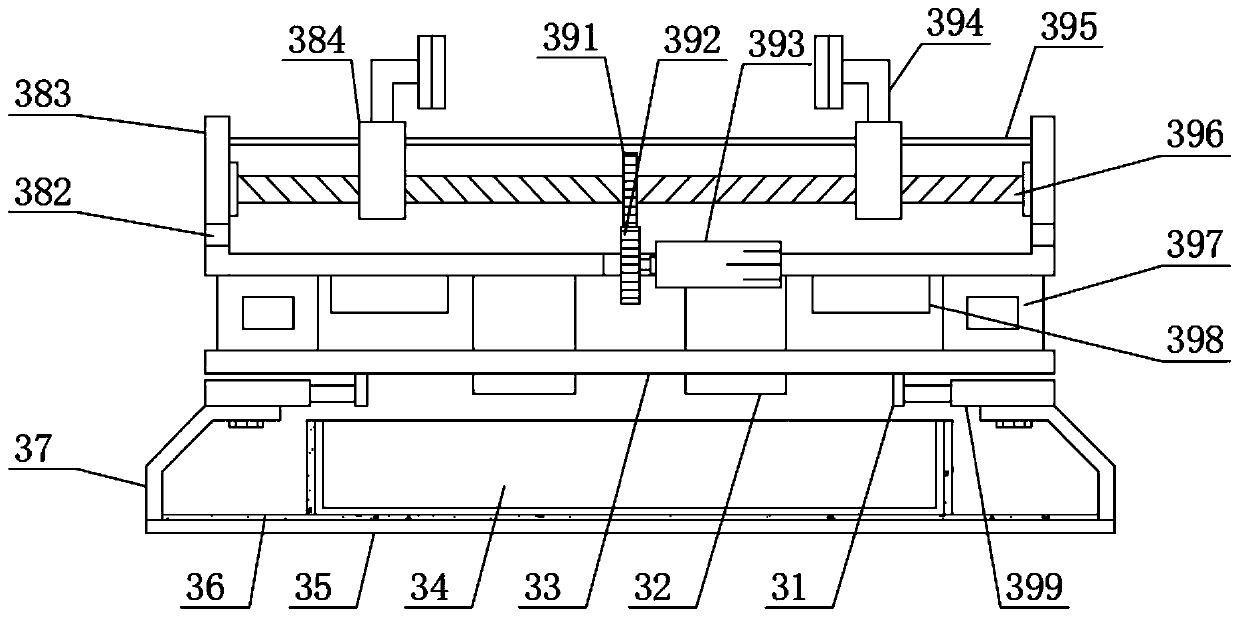

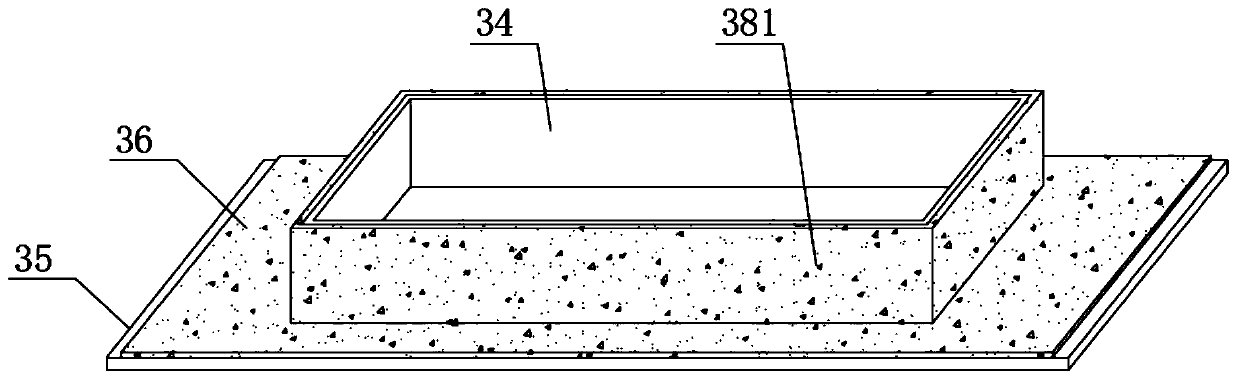

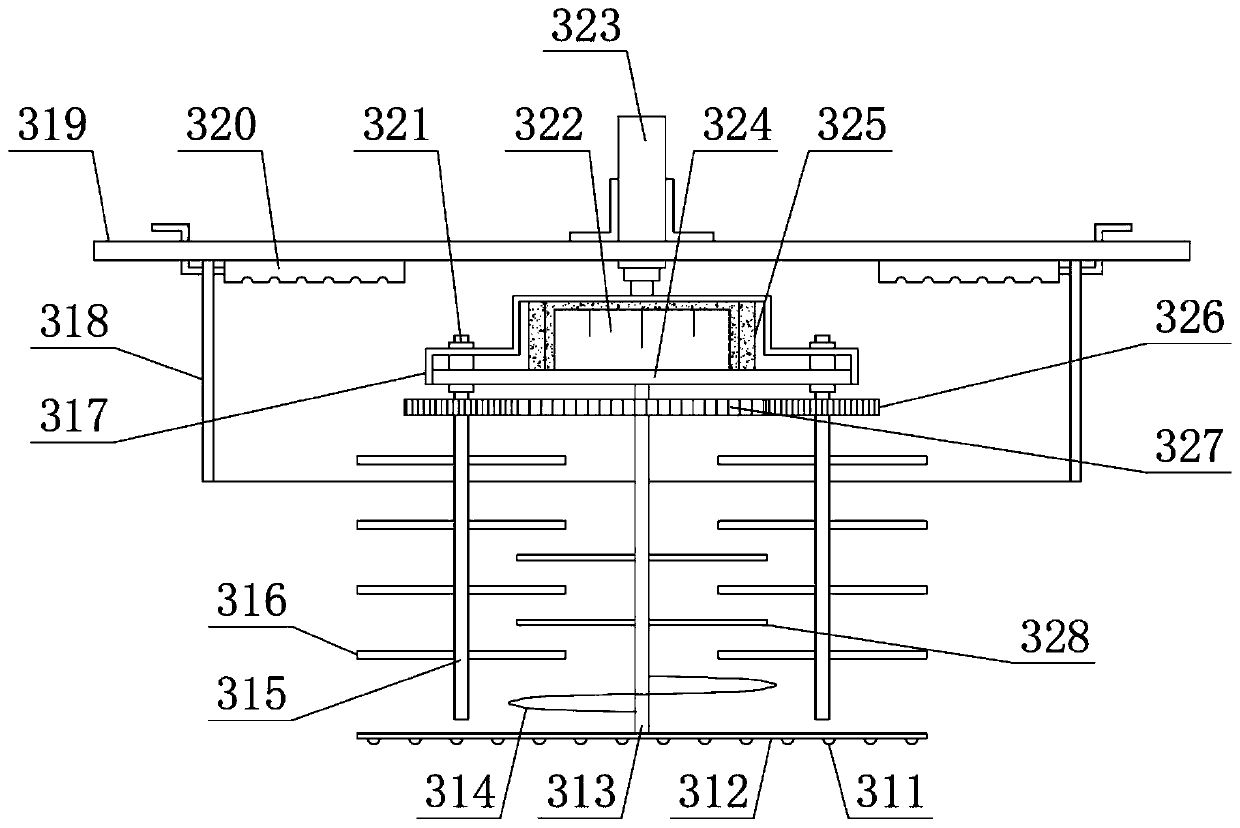

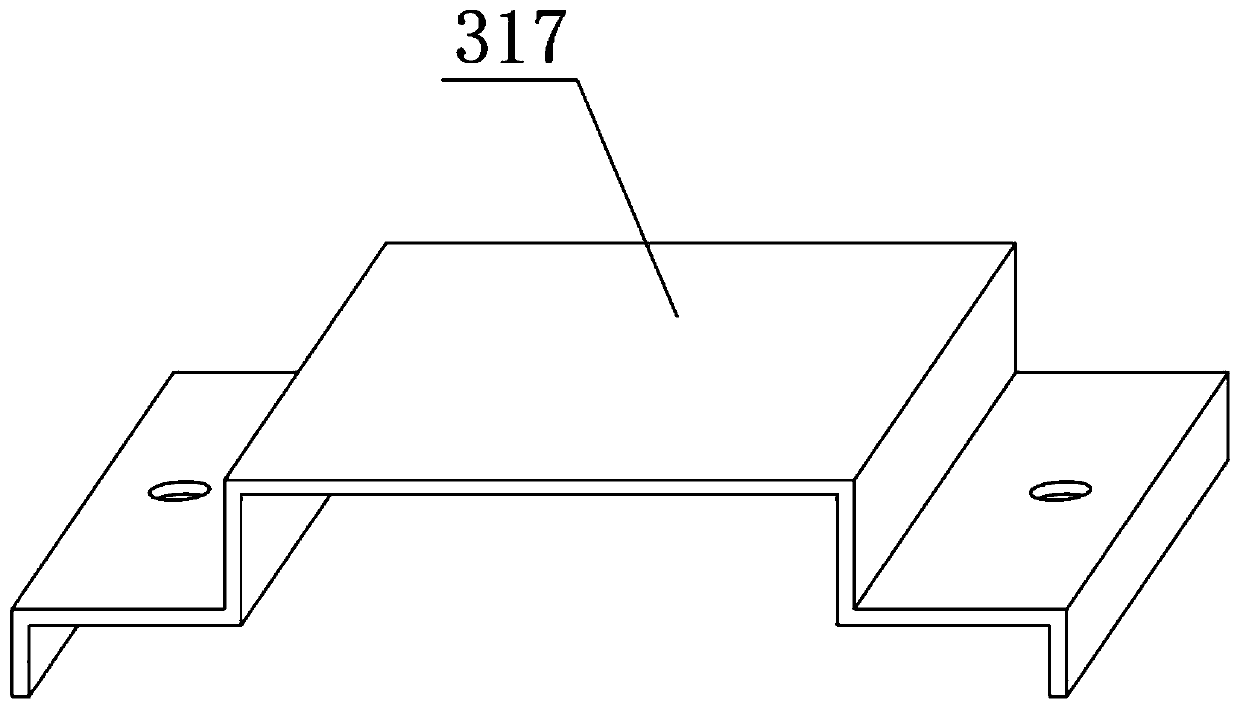

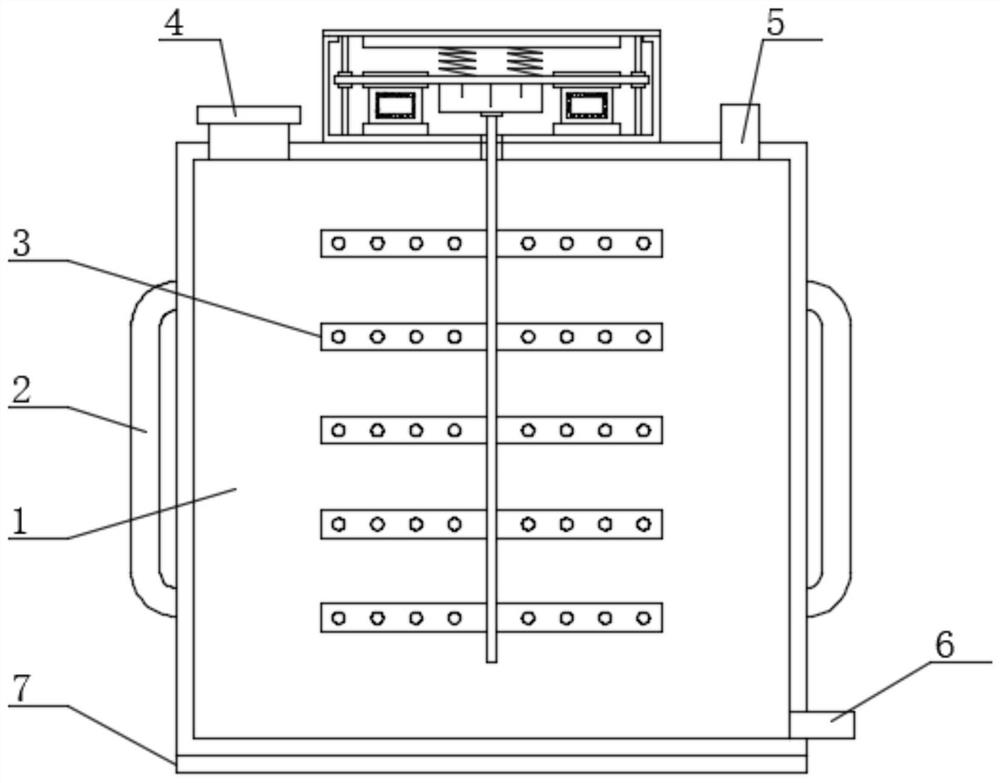

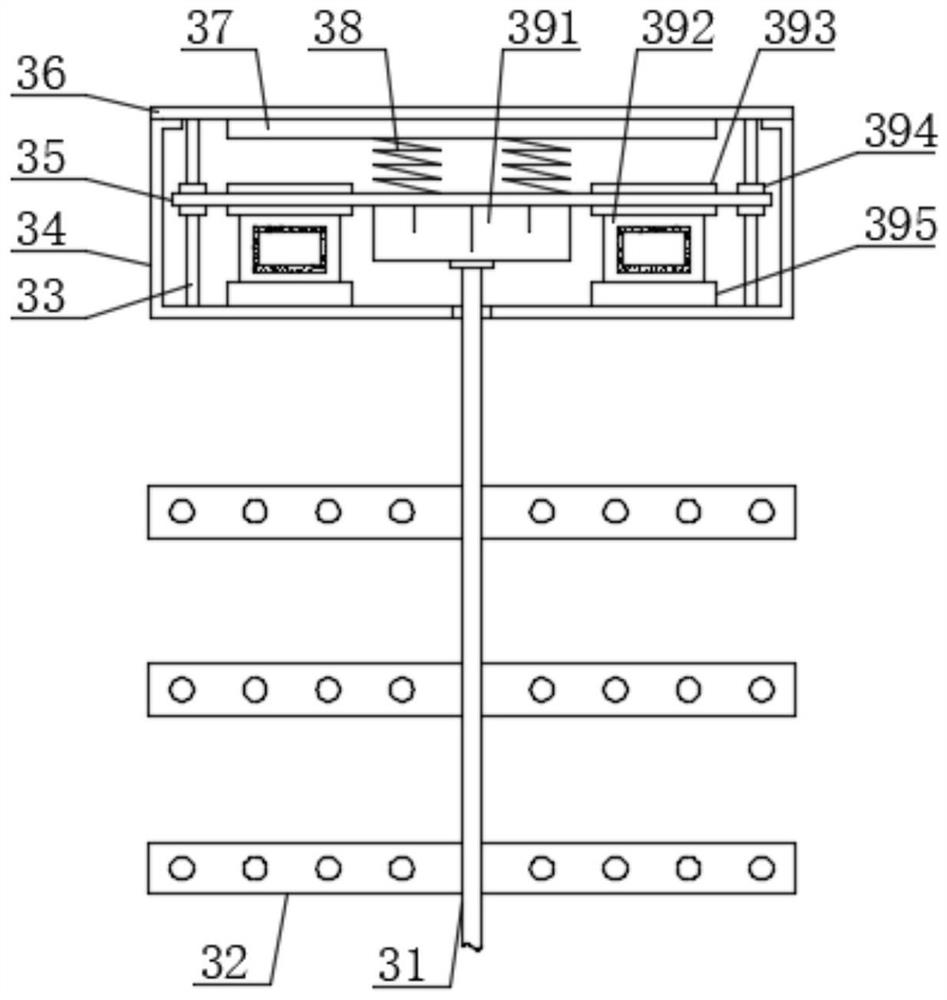

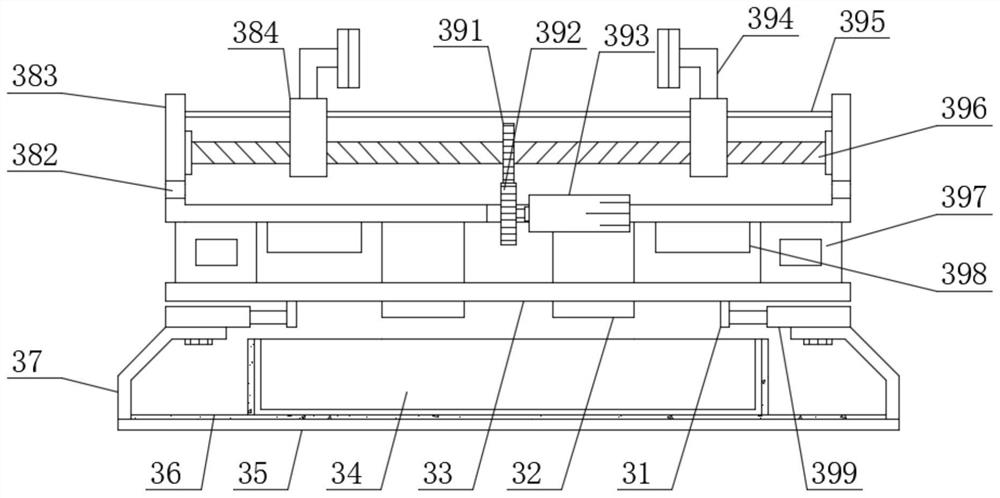

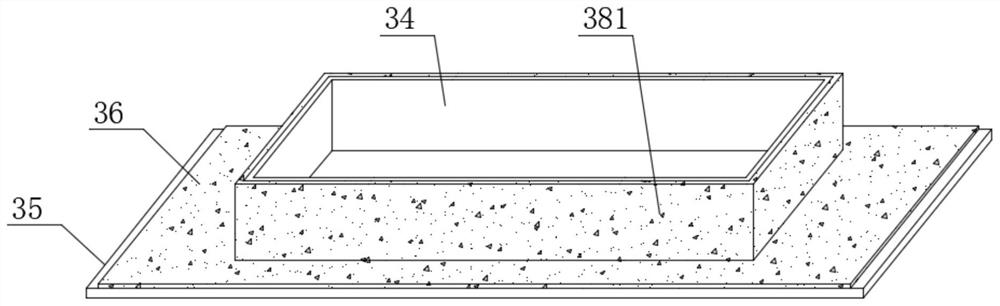

Crushing multistage screening device for building gravel aggregate

InactiveCN110732391AIncrease productivitySimple structureSievingNon-rotating vibration suppressionHydraulic cylinderArchitectural engineering

The invention discloses a crushing multistage screening device for building gravel aggregate, and belongs to the technical field of screening devices. The crushing multistage screening device comprises a screening box, a first filter plate is arranged at the top end of the screening box, a feeding hopper is arranged in the middle of the upper surface of the screening box, the top end of the screening box is further provided with a driving motor, the output end of the driving motor is provided with crushing cutters, the two sides of each crushing cutter are provided with first crushing teeth, the bottom end of the screening box is provided with a screening mechanism, the screening mechanism comprises a second supporting plate, a second filter plate is arranged above the second supporting plate, a first hydraulic cylinder corresponding to the second filter plate is arranged at one end of the upper surface of the second supporting plate, and a third filter plate is arranged above the second filter plate. The crushing multistage screening device has the advantages that the structure is simple, the use is convenient, the crushing function is good, the gravel can be crushed according tothe actual use requirements of the user, the functions of the screening device are richer, and the production efficiency of the user is improved.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

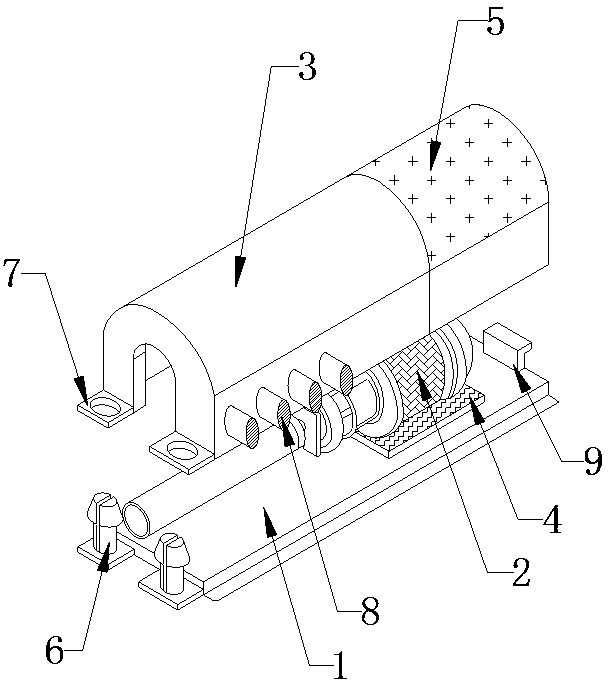

Fan unit having an axial fan with improved noise damping

ActiveUS8142139B2Good noise cancelingCompact configurationPump componentsNon-rotating vibration suppressionMobile vehicleEngineering

Due to variations arising during manufacturing, axial fans often are slightly imbalanced, resulting in noise during operation, which is undesirable in many contexts, for example when the fan is used for ventilation purposes in a motor vehicle. A fan with improved vibration and noise damping can be achieved by elastically suspending the fan wheel within a first ring formed of a hard plastic, the first ring having a tubular extension formed of a softer plastic, and serving to mechanically connect the first ring to a surrounding annular carrier part. Optionally, the first ring and extension unit can include a spring element. Preferably, the first ring and tubular extension are produced by a multi-component forming technology such as two-plastic technology. The fan is preferably driven by an electronically commutated motor (ECM).

Owner:EBM PAPST ST GEORGEN & -

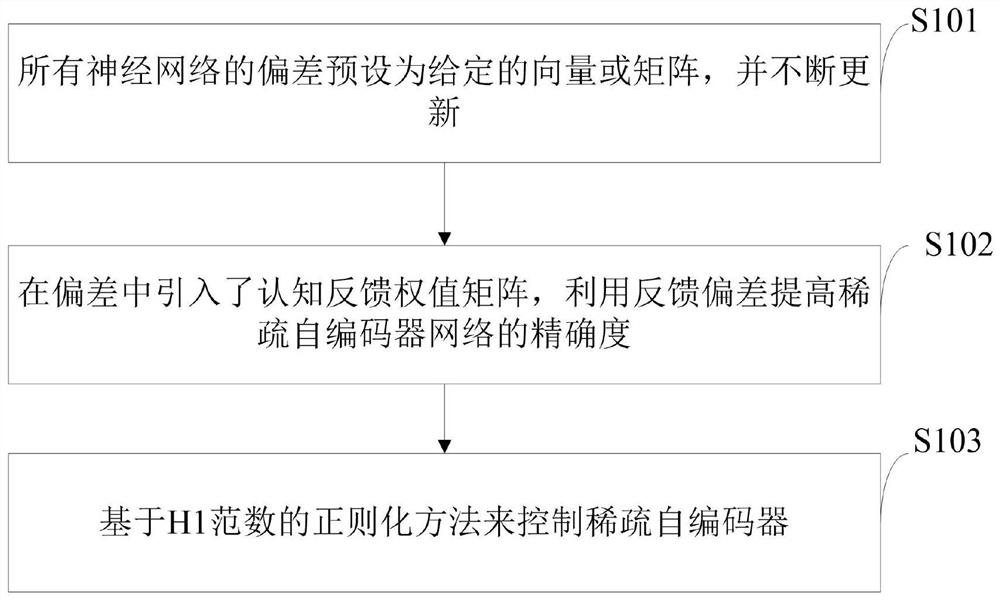

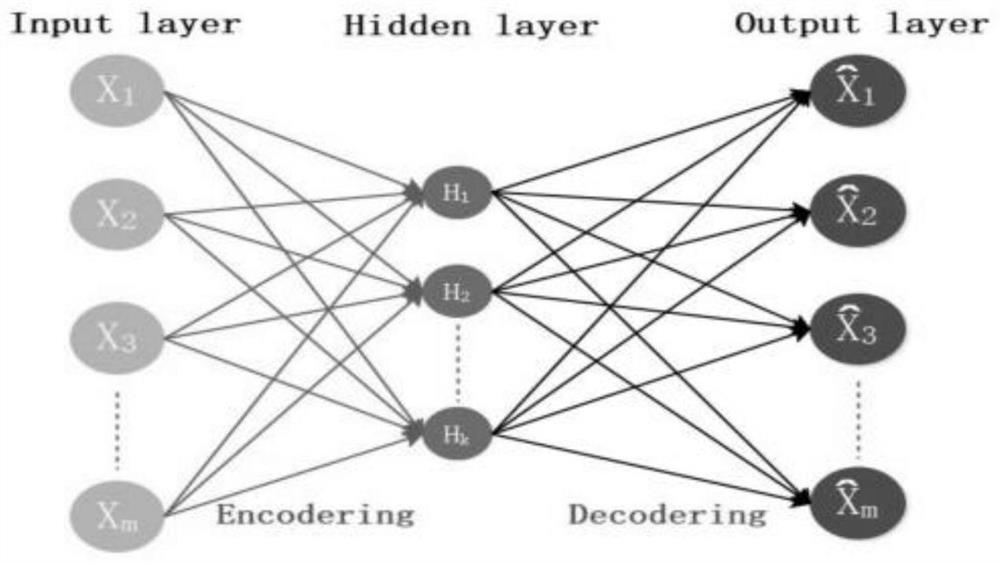

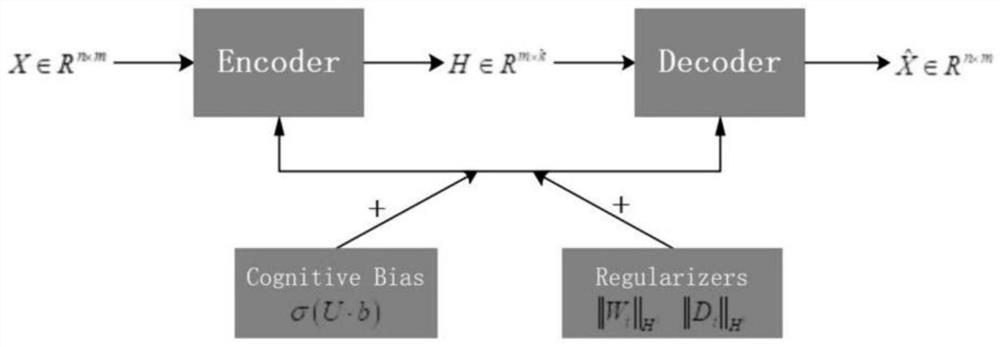

Image processing method and system based on sparse auto-encoder, medium and equipment

ActiveCN112270650AHigh precisionImplement image noise reductionImage enhancementInternal combustion piston enginesImaging processingAlgorithm

The invention belongs to the technical field of image processing, and discloses an image processing method, system, medium and device based on a sparse auto-encoder, and the method comprises the stepsof presetting the deviation of all neural networks as a given vector or matrix, and carrying out the continuous updating; introducing a cognitive feedback weight matrix into the deviation, and improving the accuracy of the sparse auto-encoder network by utilizing the feedback deviation; controlling the sparse auto-encoder based on a regularization method of the H1 norm. The invention discloses adenoising sparse auto-encoder based on feedback deviation and H1 regularization. In the model, a feedback bias matrix is introduced, so that the bias of the network can be more accurately controlled.The feedback deviation changes with the number of iterations. H1 regularization can reduce overfitting and can also prevent more important features from being excessively smoothed. Experimental results show that the method is effective and is superior to the existing DnCNN-3, DAEP and EPCNN methods.

Owner:SOUTHWEST UNIVERSITY

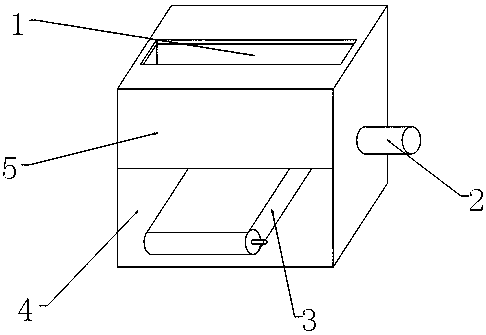

Water pump shell with good noise reduction function

InactiveCN108678947AGood noise cancelingAntisepticPositive displacement pump componentsLiquid fuel engine componentsPlastic materialsEngineering

The invention provides a water pump shell with the good noise reduction function, and relates to the field of water pumps. The water pump shell comprises a fixed base, a water pump machine, a noise reduction shell and a noise reduction pad; the noise reduction pad is arranged above the fixed base, the noise reduction pad is welded to the fixed base, the water pump machine is arranged above the noise reduction pad, the water pump machine is fixedly connected with the noise reduction pad, the noise reduction shell is arranged above the water pump machine, a clamping block is welded to the rightend of the fixed base, two pressing staple bolts are welded to the left end of the fixed base, and a partition board is fixedly connected to the surface of the noise reduction pad. The pressing staplebolts are used in cooperation with buckles, the pressing staple bolts are made of hard plastic materials, through the pressing staple bolts and the buckles which are used in a cooperation manner, thefixed base and the noise reduction shell are in fastened connection, the pressing staple bolts made of the hard plastic have the corrosion resistance property, and eight noise reduction columns are arranged. The water pumps can be well subject to noise reduction.

Owner:俞峥

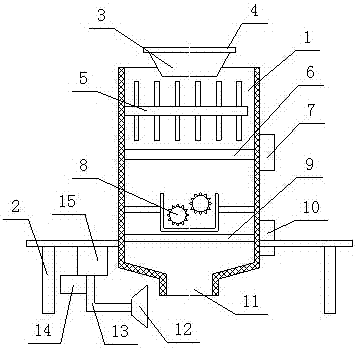

Noise reduction crusher

InactiveCN107303520ASame sizeImprove production environmentGrain treatmentsArchitectural engineeringNoise reduction

The invention discloses a noise reduction crusher, which comprises a crushing barrel and a support frame. The top of the crushing barrel is provided with a material inlet, the upper part of the crushing barrel is provided with a primary crushing device, and the bottom of the primary crushing device is provided with a vibrating Sieve plate, one end of the vibrating sieve plate is connected with a vibration drive device, the vibration drive device is located on the outer wall of the crushing barrel, the inner bottom of the crushing barrel is provided with a secondary crushing device, the bottom of the secondary crushing device is provided with a swinging sieve plate, the swinging screen One end of the plate is connected with a swing driving device, the bottom of the crushing barrel is provided with a discharge port, the discharge port is provided with a dust collection cover, and a suction pipe is connected outside the dust collection cover, and one end of the suction pipe is connected to the dust suction The hood is connected, and the other end is connected with a suction fan and a waste box. The invention can be crushed multiple times in the same equipment, the crushing effect is good, the particle size obtained after crushing is basically the same, and has good noise reduction function, which effectively improves the production environment of workers.

Owner:苏阳

Polishing device for metal surface treatment

ActiveCN111266962AImprove grinding effectImprove work efficiencyGrinding carriagesGrinding drivesPolishingEngineering

The invention discloses a polishing device for metal surface treatment and belongs to the technical field of metal surface treatment. The polishing device comprises a shell, wherein a polishing mechanism is arranged at the top end of the shell; the bottom end of the polishing mechanism is fixedly connected with the shell in a welding manner; a fixing mechanism is arranged in the shell and comprises a second support plate; a first support plate is arranged above the second support plate; support pieces are arranged at the two ends of the upper surface of the second support plate; an electric telescopic rod is arranged at the top ends of the support pieces; a second limiting plate corresponding to the electric telescopic rod is arranged at the two ends of the lower surface of the first support plate; and a limiting base is arranged above the first support plate. The polishing device is simple in structure and convenient to use, has an excellent fixing function, and can adjust the workpiece position during the polishing process to realize a better polishing effect to the workpiece and improve the working efficiency of a user.

Owner:湖南戎升正达智能装备有限公司

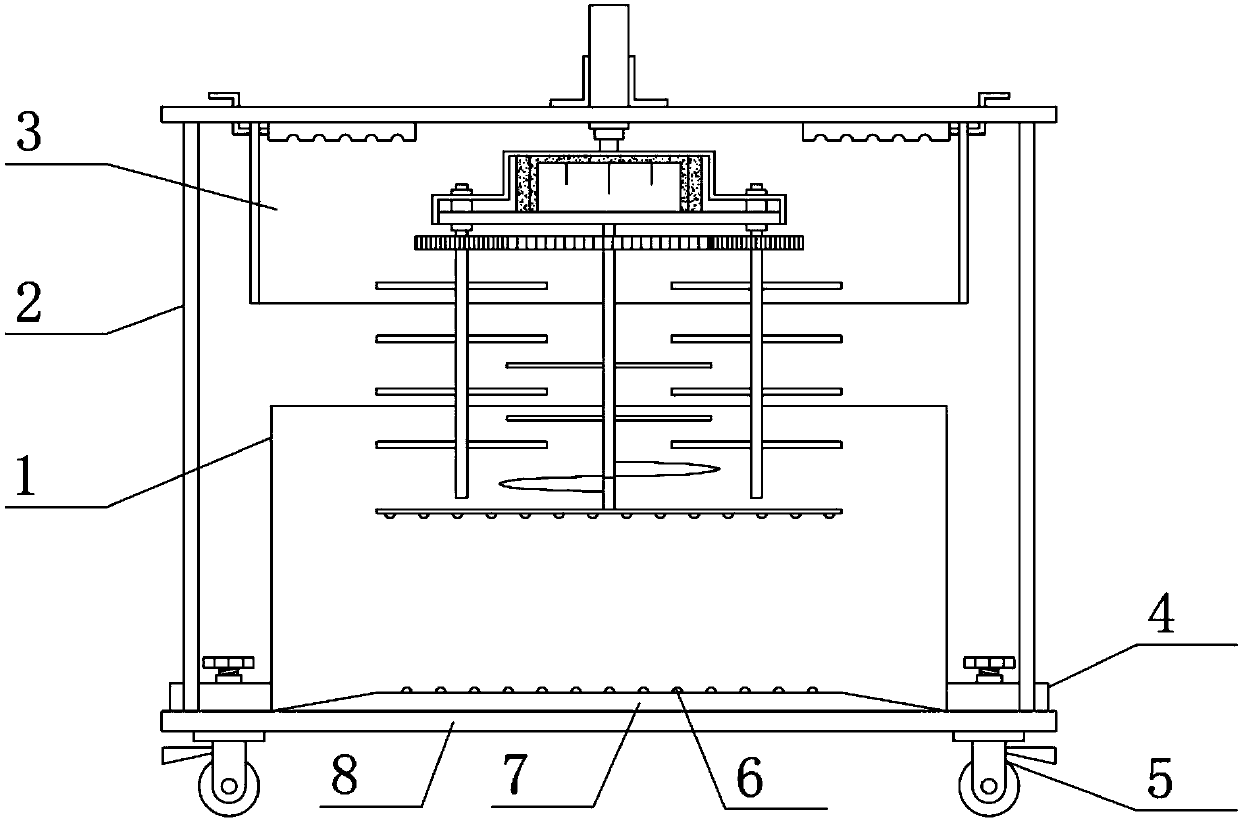

Environment-friendly waste paper regeneration treatment device

InactiveCN110616582AImprove crushing effectReduce noisePulp beating/refining methodsRaw material divisionEnvironmental resistancePulp and paper industry

The invention discloses an environment-friendly treatment device for waste paper regeneration. The invention belongs to the technical field of environmental protection equipment. The device includes afirst support plate, wherein a crushing box is arranged on the upper surface of the first supporting plate; discharge pipes are arranged on the two sides of the crushing box; a crushing mechanism isarranged above the first supporting plate and comprises a second supporting plate, a supporting piece is arranged at the joint of the second supporting plate and the first supporting plate, water outlet pipes are arranged at the two ends of the lower surface of the second supporting plate, a third supporting plate is arranged below the second supporting plate, and a driving motor is arranged on the upper surface of the third supporting plate. The device is simple in structure, convenient use, when the waste paper treatment device is used, waste paper and water are mixed while the waste paper is crushed through mutual cooperation of the crushing part and the stirring part, and secondly, the waste paper can be crushed through the crushing part at different heights and can be ground, so thatthe waste paper crushing effect of the treatment device is better, and the production efficiency of a user is improved.

Owner:黎梦雅

An easy-to-use photocatalyst spraying device

Owner:杭州美鸭科技有限公司

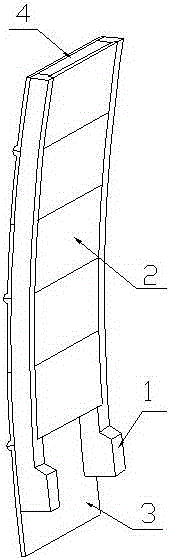

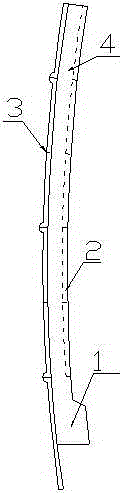

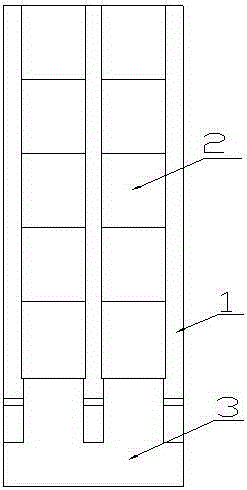

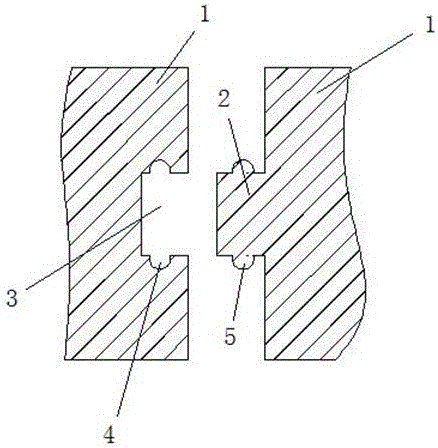

Bonding riveting installation structure of composite top cover used for rail traffic vehicle

The invention discloses a bonding riveting installation structure of a composite top cover used for a rail traffic vehicle and belongs to the technical field of rail traffic vehicle light weight and passive safety. The structure comprises the composite top cover and a vehicle body upper suspension girder. The upper surface on the inner side of the vehicle body upper suspension girder is of a three-level stair structure, the outer side of the vehicle body upper suspension girder is made of a metal section of an inequilateral right-angle structure, the lower surface of the side edge of the composite top cover is of a two-level stair structure, a one-level stair structure of the lower surface of the side edge of the composite top cover and a two-level stair structure of the upper surface on the inner side of the vehicle body upper suspension girder are bonded through sealant, and elastic glue is arranged between the one-level stair structure of the lower surface of the side edge of the composite top cover and the three-level stair structure of the upper surface on the inner side of the vehicle body upper suspension girder which are connected through rivet nuts and bolts; and the rivetnuts are embedded in the one-level stair structure of the lower surface of the side edge of the composite top cover, and bolt holes matched with the rivet nuts are formed in the corresponding positions on the three-level stair structure of the vehicle body upper suspension girder. The structure is suitable for being applied and popularized in the technical field of rail traffic vehicle light weight and passive safety.

Owner:成都西交轨道交通装备科技有限公司

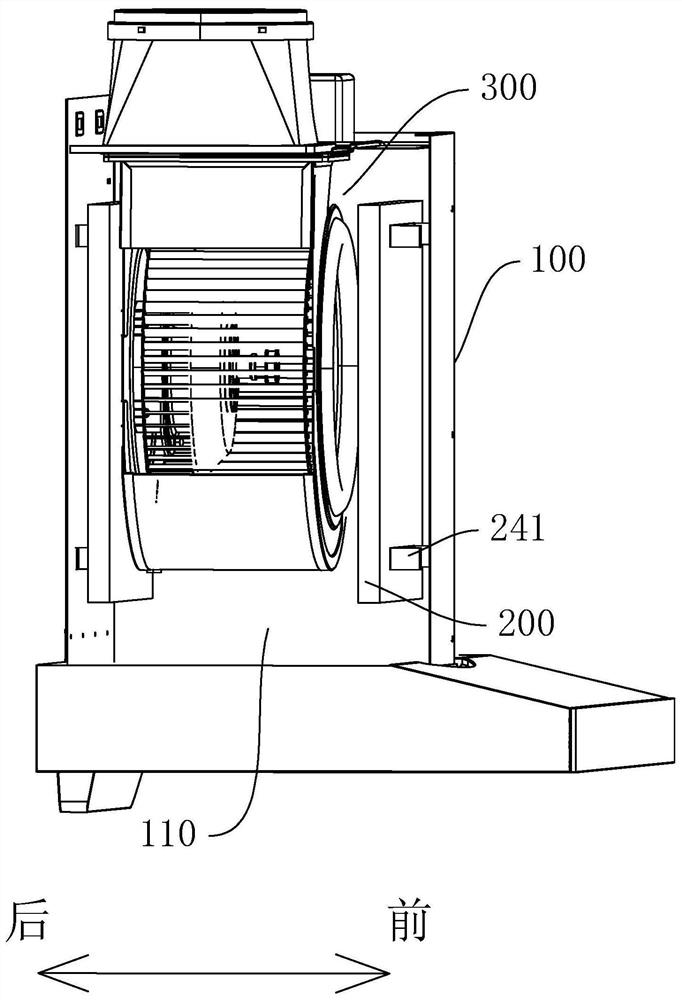

Noise reducing extractor hood

PendingCN111895474ASatisfy the working environmentEffective absorption and noise reductionDomestic stoves or rangesLighting and heating apparatusNoiseThin membrane

The invention discloses a noise reducing extractor hood. The extractor hood comprises a crate; the crate is provided with a fume collecting cavity; a draught fan device is installed inside the fume collecting cavity; a first noise reducing structure is arranged between the crate and the draught fan device; the first noise reducing structure comprises a first thin fill close to the draught fan device and a second thin film close to the inner wall of the fume collecting cavity; and a sealed first noise reducing cavity is formed between the first thin film and the second thin film. In the operation process of the extractor hood, a noise sound wave generated by operation of the draught fan device enters the first noise reducing cavity through the first thin film, and exits through the second thin film; under resonance action of the first thin film and the second thin film as well as the first noise reducing cavity, a sound absorption bandwidth is expanded and can absorb sound waves of different frequencies so the sound waves of different frequencies can be absorbed and reduced effectively; and the sealed first noise reducing cavity can effectively prevent fume from entering, working environment of the extractor hood is satisfied, and a good noise reducing function is maintained.

Owner:GUANGDONG MACRO GAS APPLIANCE +1

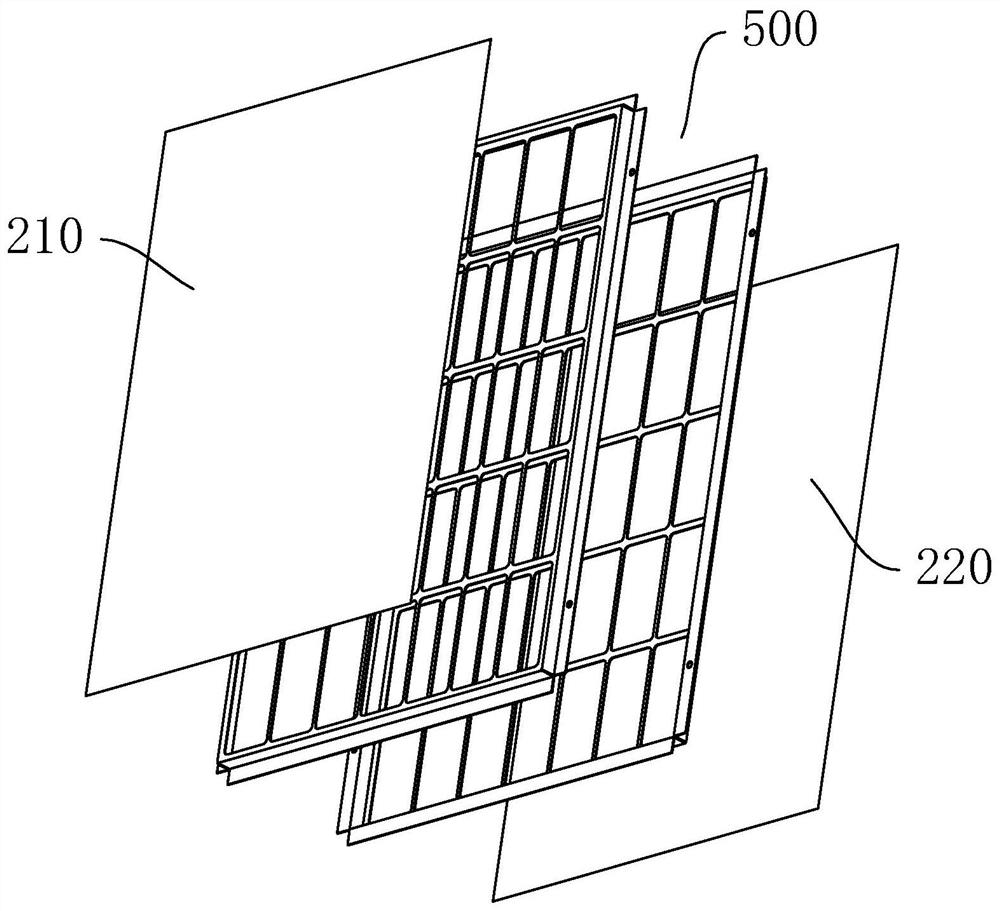

soundproof ventilation window

ActiveCN107191117BPrevent incomingAchieve convectionVentilation arrangementNoise insulation doors/windowsEngineeringSoundproofing

The invention relates to soundproof ventilation window which comprises a framework and soundproof glass. Rotating shafts are arranged on the framework in parallel and rotationally sleeved with ventilation barrels. Air guide blades are rotationally and symmetrically arranged on the barrel surfaces of the ventilation barrels. The edges of the air guide blades are folded inwards to form circular arc edges. The soundproof glass is provided with ventilation strips with the edges being concave inwards to be spliced into circular arc surfaces. The circular arc surfaces and the circular arc edges are the same in curvature and are tightly attached. The diameter width of the ventilation strips is smaller than the distance between every two adjacent air guide blades. The soundproof ventilation window is novel and unique in structure and delicate and decent in appearance; and on the basis of effective soundproofing, ventilation of a room is ensured, and the living comfort of the room is effectively improved.

Owner:CHONGQING JINKE ARCHITECTURAL DESIGN & RES INST CO LTD

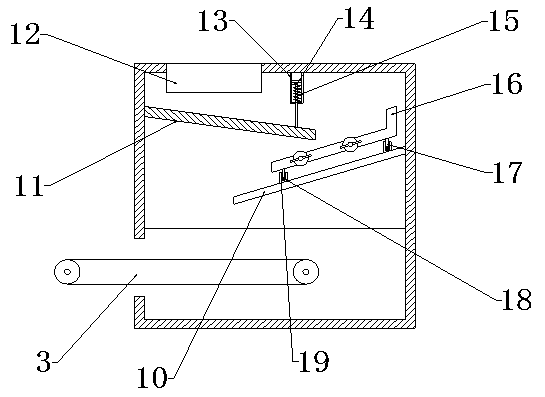

Discharging device for high-efficiency rolling noise reduction type industrial machine

InactiveCN108946074AReduce working noiseSmooth rotationConveyor partsElectric machineryIndustrial machine

The invention provides a discharging device for a high-efficiency rolling noise reduction type industrial machine. The discharging device comprises a motor, a conveyer belt, a discharging hole, a hollow box, a feeding plate, a feeding hole, hollow barrels, T-shaped rods I, springs I, an L-shaped material plate, T-shaped rod IIs, springs II and a columnar tank, wherein the motor is fixed at the right end of the hollow box; the discharging hole is formed in the lower part of the front end surface of the hollow box; the conveyer belt is arranged in the discharging hole; the feeding plate is arranged below the feeding hole; the hollow barrels are arranged at the left part and right part of the upper end surface of the interior of the hollow box; the T-shaped rods I are connected to the hollowbarrels through the springs I; the T-shaped rods II are arranged at the four corners of the lower end surface of the T-shaped rods II; and the lower ends of the T-shaped rods II are connected to the columnar tank through the springs II. The discharging device realizes the buffering of processing products; the working noise of the discharging device is substantially reduced; and the discharging device is convenient to use and low in construction cost and has an excellent noise reduction function and high reliability.

Owner:王小莉

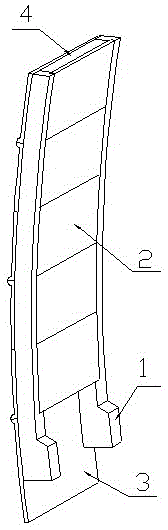

a sound barrier

ActiveCN103526700BImprove sound absorptionHigh strengthNoise reduction constructionSound barrierCeramic composite

The invention discloses a sound barrier. Including supporting ribs, sound-absorbing panels and the back, a hollow structure is formed between the sound-absorbing panels and the back panel, and the supporting ribs are consolidated on the railway foundation; the sound-absorbing panels are micropores with a disorderly connected three-dimensional mesh structure The ceramic composite board; the sound barrier formed by the supporting rib column, the sound-absorbing panel and the back plate is an arc surface, and the concave surface of the arc surface faces the railway traffic surface; the lower edge of the back plate protrudes from the bottom of the supporting rib column. The invention adopts a three-layer hollow sound-absorbing sound barrier structure, and the sound-absorbing board adopts a microporous ceramic composite board, which not only has excellent noise reduction function, but also has better processing performance; the noise reduction barrier adopts an arc surface structure It has better sound absorption and reflection performance, and can further reduce noise spillage. Tests have proved that the sound barrier of the present invention has better sound absorption performance, high sound absorption coefficient, wide sound absorption frequency band, and good low-frequency sound absorption effect; the prefabricated structure of the sound barrier of the present invention is more convenient to process and install, and has higher construction efficiency.

Owner:CHENGDU ZHONGHONG RAIL TRANSIT ENVIRONMENTAL PROTECTION IND +1

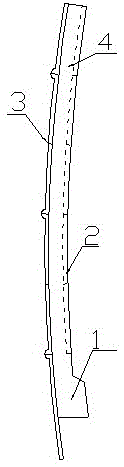

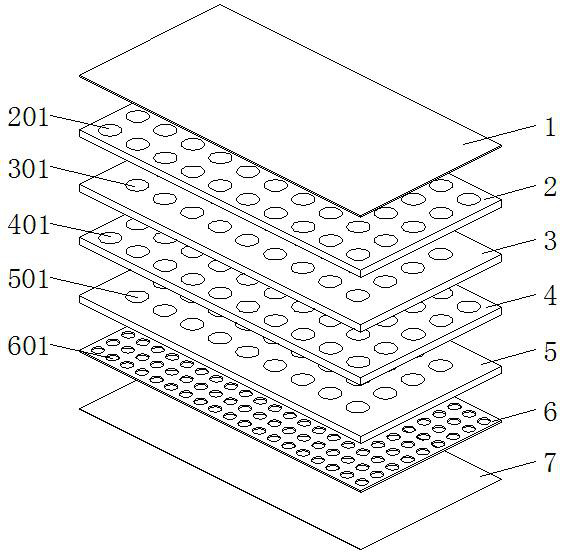

A kind of decorative veneer for noise-reducing wall surface and preparation method thereof

ActiveCN110315605BImprove Noise CancellationImprove sound insulationCovering/liningsWood veneer joiningSingle plateNoise

The invention discloses a decorative veneer for a wall that can reduce noise. The veneer sequentially includes a decorative ply, a shock-absorbing ply I fixed and bonded to the lower end of the decorative ply, and a shock-absorbing ply I from top to bottom. The sound-absorbing plate layer I fixedly pressed at the lower end, the sound-absorbing plate layer II fixedly pressed at the lower end of the sound-absorbing plate layer II, the shock-absorbing plate layer II fixedly pressed at the lower end of the sound-absorbing plate layer II, and the lower end surface of the shock-absorbing plate layer II are all coated with The rubber surface layer of the cloth is bonded to the release film layer at the lower end of the rubber surface layer. The invention also discloses a method for preparing a veneer for noise-reducing wall surface decoration, which includes the following steps: Step 1: preparing materials; Step 2: Plate opening; Step 3: Blank assembly; Step 4: Veneer forming; Step 5: Glue application; The combined structure of the ply II makes the entire veneer have good sound-absorbing and sound-insulating functions relative to the upper and lower directions.

Owner:JIAXING GAOQUAN WOOD

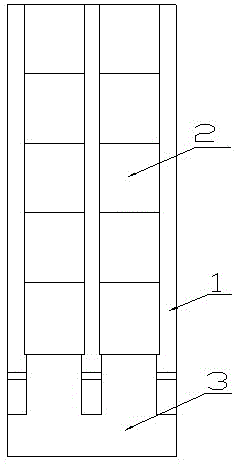

A polyvinyl chloride foam tube

ActiveCN105673953BHigh circumferential rigiditySave raw materialsSynthetic resin layered productsRigid pipesPolyvinyl chlorideNoise reduction

The invention provides a polyvinyl chloride foam tube. The polyvinyl chloride foam tube is composed of an inner solid wall layer, an outer solid wall layer and a middle foam core layer. The inner solid wall layer and the outer solid wall layer are composed of, by mass, 25-35 parts of compact polyvinyl chloride resin, 80-90 parts of loose polyvinyl chloride resin, 2-4 parts of stabilizers, 10-30 parts of processing agents A and 11-15 parts of fillers. The middle foam core layer is composed of, by mass, 1-5 parts of compact polyvinyl chloride resin, 80-100 parts of loose polyvinyl chloride resin, 2-4 parts of stabilizers, 4-6 parts of processing agents B and 5-15 parts of fillers. The polyvinyl chloride foam tube provided by the invention is resistant to corrosion, light, resistant to shock and is capable of preserving heat, the annular rigidity is about eight times higher than that of common UPVC tubes, raw materials can be saved by 25% or more compared with solid wall tubes, the noise reduction function is obvious, and noise can be reduced by 2-3 db compared with the solid wall tubes.

Owner:SHANGHAI SHANGSU HLDG GRP

A kind of rubber powder modified cement concrete pavement and its manufacturing method

ActiveCN107188488BEffective digestionExtended service lifeIn situ pavingsSolid waste managementCelluloseWear resistant

The invention discloses a rubber powder modified cement concrete pavement and a manufacturing method thereof. The rubber powder modified cement concrete pavement is characterized by being prepared from the following raw materials in parts by weight: 25 to 30kg / m<3> of rubber powder, 300 to 330kg / m<3> of 425 cement, 550 to 590kg / m<3> of river sand, 1080 to 1180kg / m<3> of broken stone, 135 to 165kg / m<3> of water, 5 to 7kg / m<3> of water reducing agents, 3 to 4kg / m<3> of phthalic ester coupling agents, 2 to 3kg / m<3> of rubber latex, 3 to 4kg / m<3> of hydrophobic modification cellulose, 15 to 20kg / m<3> of lignin, 80 to 110kg / m<3> of granulitic blast-furnace ore slag powder and the like. The raw materials are effectively mixed to obtain the concrete. The rubber powder modified cement concrete pavement has the characteristics that the properties of anti-folding intensity, anti-impact performance, bottom plate anti-impact and anti-abrasion performance, wear-resistant performance, temperature shrinkage, dry shrinkage performance, freezing resistance performance, ultimate strain capability, noise reducing performance, volume weight, corrosion resistance and the like of the rubber powder modified cement concrete pavement are superior to those of the ordinary cement concrete pavement; the later-stage maintenance cost is lower than that of the ordinary cement concrete pavement, and the like.

Owner:广西航务建设工程有限公司

A Multi-View Dense Point Cloud Data Fusion Method Based on Bilateral Filter

ActiveCN104050639BImprove efficiencyGood noise cancelingImage enhancementUsing optical meansPoint cloudMean-shift

The invention discloses a multi-view dense point cloud data fusion method based on a two-sided filter and belongs to the technical field of optical three-dimensional non-contact measurement. The multi-view dense point cloud data fusion method based on the two-sided filter comprises the steps that (1) multi-view dense point cloud data are input, (2) a topological relation is established, (3) point data classification is conducted based on the two-sided filter, (4) Mean-shift clustering fusion is conducted, and (5) a fusion result is output. When the method is used for fusing the multi-view dense point cloud data, the two-sided filter and the Mean-shift clustering are introduced, recognition of an overlapping region and a non-overlapping region is not needed, in this way, the efficiency of fusing a great number of multi-view dense point cloud data is improved, the smoothness of a point cloud obtained after fusion are improved, and the defects of an existing point cloud fusion technology are effectively overcome.

Owner:XIDIAN UNIV

Grinding device for metal surface treatment

ActiveCN111266962BImprove grinding effectImprove work efficiencyGrinding carriagesGrinding drivesPolishingEngineering

Owner:湖南戎升正达智能装备有限公司

An ultra-microporous ceramic sound-absorbing barrier and its manufacturing method

InactiveCN103669233BImprove sound absorptionHigh strengthNoise reduction constructionCeramic shaping apparatusSound barrierCeramic composite

Owner:陈松

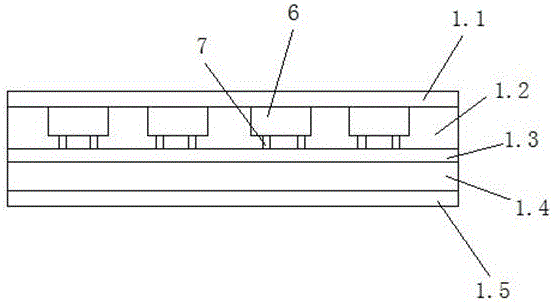

Heat preservation and sound insulation polyurethane plate and preparation method of polyurethane core layer of polyurethane plate

InactiveCN105926792AGood noise cancelingIncrease insulation functionHeat proofingSound proofingEngineeringUltimate tensile strength

The invention relates to a polyurethane plate, and particularly provides a heat preservation and sound insulation polyurethane plate. The heat preservation and sound insulation polyurethane plate comprises an upper color plate and a lower color plate. The lower surface of the upper color plate is connected with a polyurethane core layer. A sound adsorption layer is arranged on the lower surface of the polyurethane core layer. A heat preservation material plate is arranged between the sound adsorption layer and the lower color plate and is thinner than the polyurethane core layer. At least two sound adsorption grooves are formed in the surface, making contact with the upper color plate, of the polyurethane core layer. The lengths of the sound adsorption grooves and the length of the polyurethane core layer are consistent. A plurality of through holes are formed in the surface, opposite to the sound adsorption grooves, of the upper color plate. Sound adsorption holes are formed in the bottoms of the sound adsorption grooves and are connected with the sound adsorption layer. The heat preservation and sound insulation polyurethane plate provided by the invention is simple in structure, low in weight, high in structural strength, close in connection, good in heat preservation performance and capable of adsorbing sound and reducing noise. A preparation method of the polyurethane core layer is simple in manufacturing process and high in production efficiency, and the prepared polyurethane core layer is good in heat preservation performance and high in heat conductivity.

Owner:安徽瑞联节能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com