Environmentally friendly ceramic raw material crushing device

A crushing device and ceramic raw material technology, applied in grain processing, etc., can solve problems such as poor plasticity, and achieve the effects of improving the production environment, good noise reduction function, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

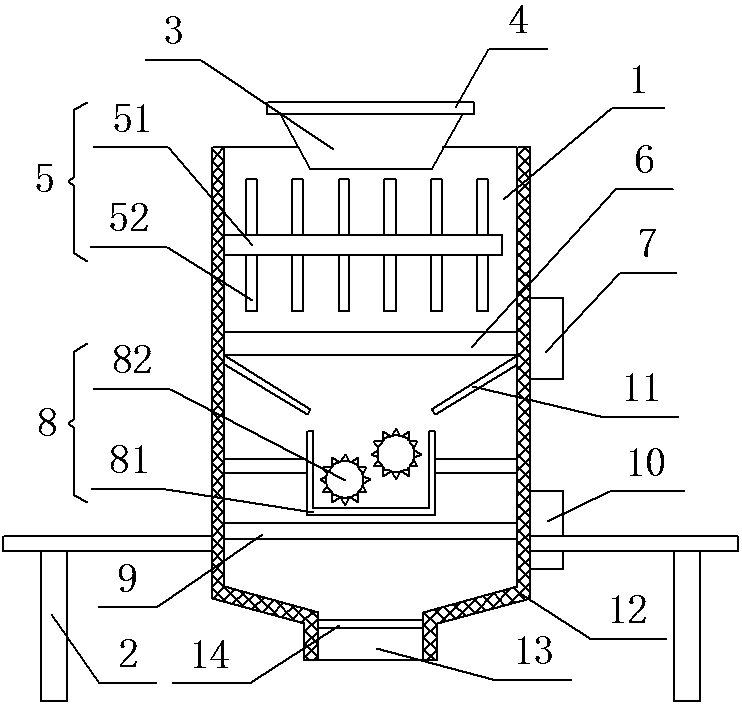

[0010] Embodiment 1: as figure 1 As shown, the present invention includes a crushing barrel 1 and a support frame 2, the crushing barrel 1 is located on the support frame 2, the top of the crushing barrel 1 is provided with a material inlet 3, and the material inlet 3 is provided with a matching cover 4, The upper part of the crushing barrel 1 is provided with a primary crushing device 5, and the primary crushing device 5 includes a rotating shaft 51 and several crushing hammers 52 evenly arranged on the rotating shaft 51. One end of the rotating shaft 51 is connected with a motor, and the motor is located in the crushing barrel 1. In addition, a vibrating sieve plate 6 is provided below the primary crushing device 5, and the vibrating sieve plate 6 is located in the middle of the crushing barrel 1, and one end of the vibrating sieve plate 6 is connected with a vibration driving device 7, and the vibration driving device 7 is located on the outer wall of the crushing barrel 1. ...

Embodiment 2

[0011] Embodiment 2: the same as the above embodiment 1, wherein the discharge port 13 in the crushing barrel 1 is provided with an electrostatic precipitator net 14 .

[0012] In the present invention, the stone is poured from the feed port 3, and the cover body 4 is covered. The stone is crushed on the vibrating sieve plate 6 by the primary crushing device 5, and the stone crushed to a certain particle size falls from the vibrating sieve plate 6, passes through The role of the plate 11 is to drop the stone into the secondary crushing device 8, and the unbroken stone continues to be crushed in the primary crushing device 5, and the stone is subjected to secondary crushing in the secondary crushing device 8 to be broken into smaller particles. diameter, sifted out through the swinging sieve plate 9, taken out from the discharge port 13, and when passing through the discharge port 13, the dust on the stones is adsorbed by the electrostatic precipitator net 14, so that the dust o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com