A polyvinyl chloride foam tube

A polyvinyl chloride and foamed pipe technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipes, etc., can solve the problems of heavy, difficult to form, and high manufacturing costs, and achieve noise reduction, noise reduction, and significant savings. The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

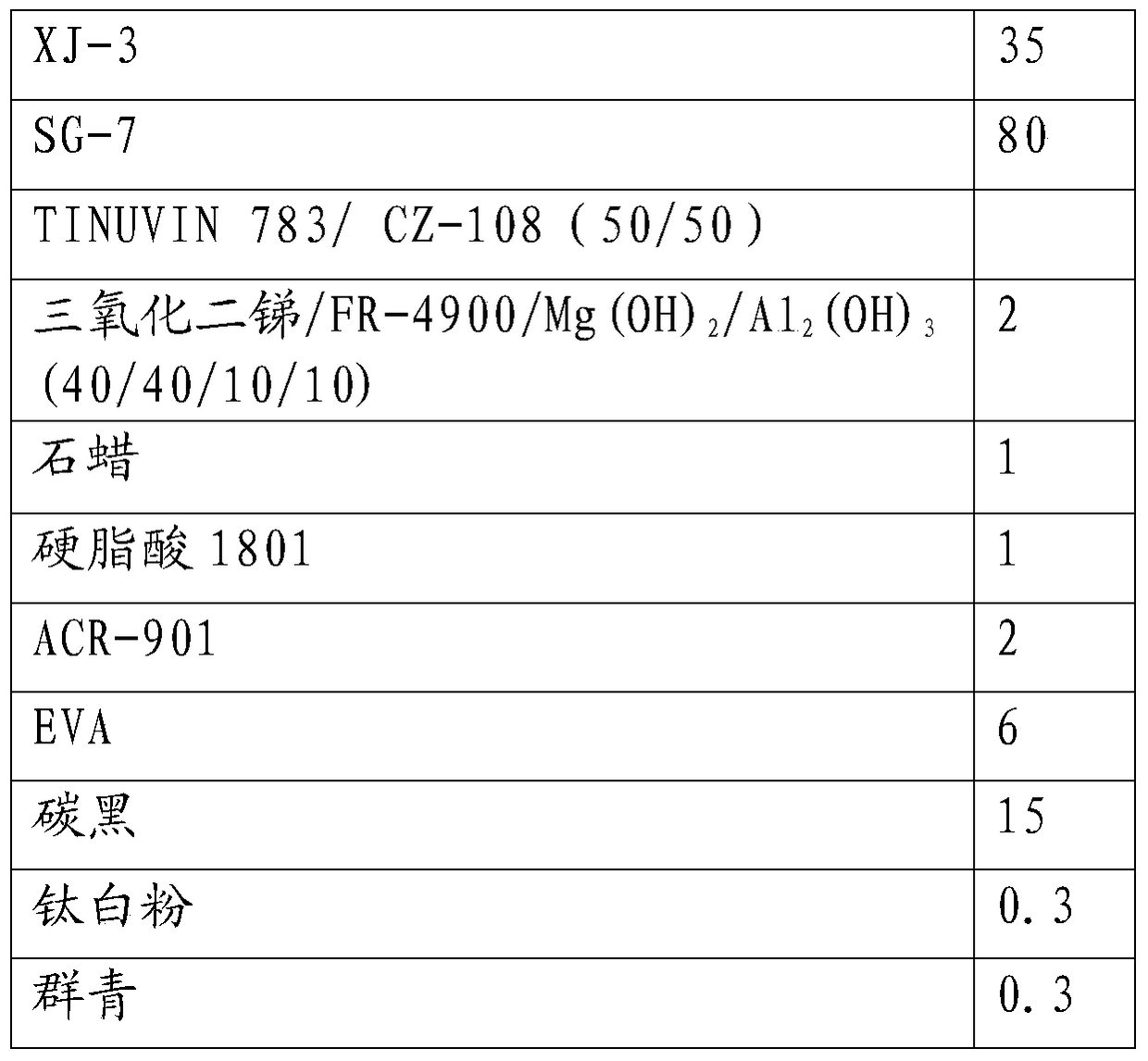

[0033] Embodiment 1, polyvinyl chloride foam pipe 1#

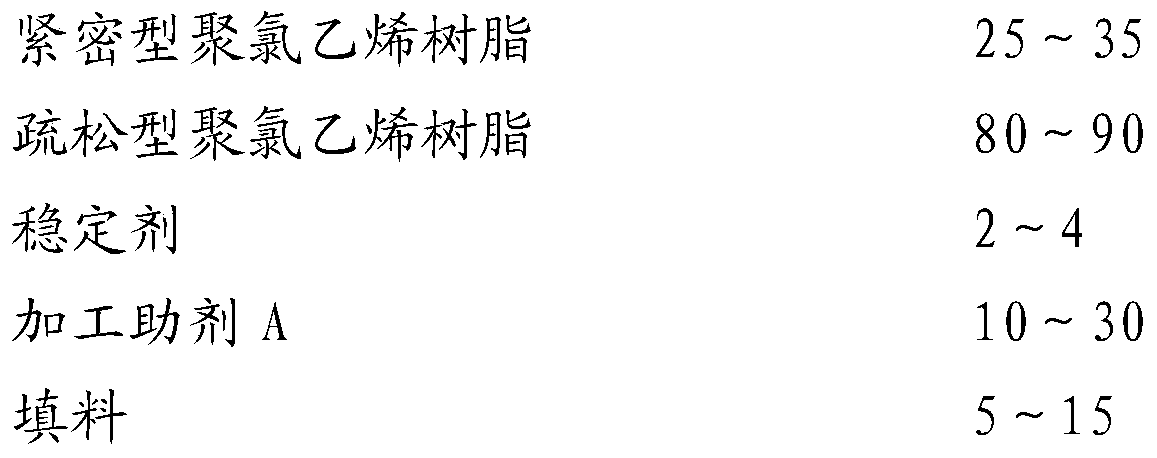

[0034] The inner and outer solid wall layers are made of the following components in parts by mass:

[0035] XJ-1

25

SG-5

90

CZ-108

2

paraffin

0.5

ACR-201

1

CPE130A

2

Titanium dioxide

0.5

15

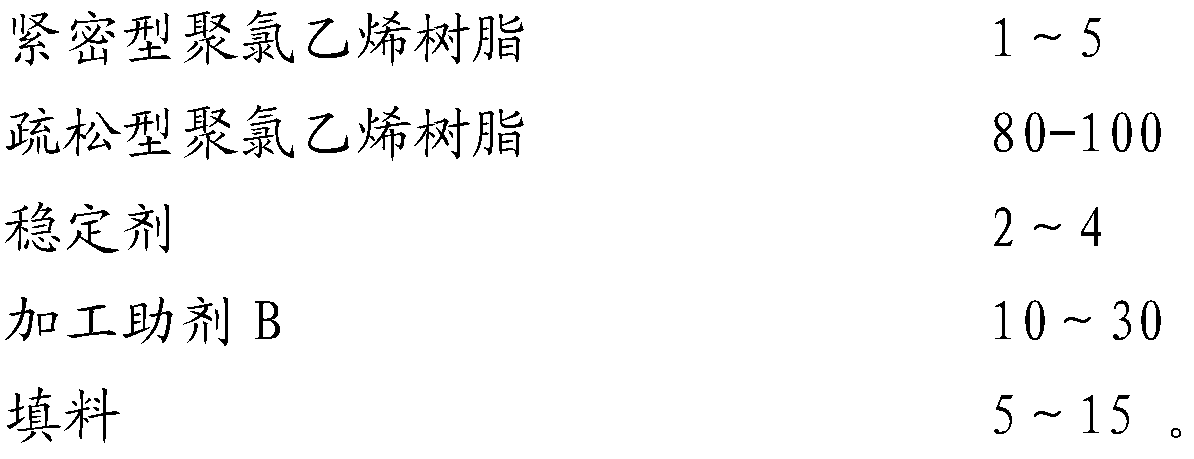

[0036] The middle foam core layer is made of the following components in parts by mass:

[0037] XJ-1

Embodiment 2

[0038] Embodiment two, polyvinyl chloride foam pipe 2#

[0039] The inner and outer solid wall layers are made of the following components in parts by mass:

[0040]

[0041] The middle foam core layer is made of the following components in parts by mass:

[0042] XJ-1

Embodiment 3

[0043] Embodiment three, polyvinyl chloride foam pipe 3#

[0044] The inner and outer solid wall layers are made of the following components in parts by mass:

[0045]

[0046] The middle foam core layer is made of the following components in parts by mass:

[0047] XJ-8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com