Heat preservation and sound insulation polyurethane plate and preparation method of polyurethane core layer of polyurethane plate

A polyurethane board, thermal insulation and sound insulation technology, which is applied in thermal insulation, sound insulation, building components, etc., can solve the problems of time-consuming and laborious installation of brick walls, poor thermal insulation performance of color steel plates, and impact on the lives of indoor personnel, achieving high production efficiency and good thermal insulation performance , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

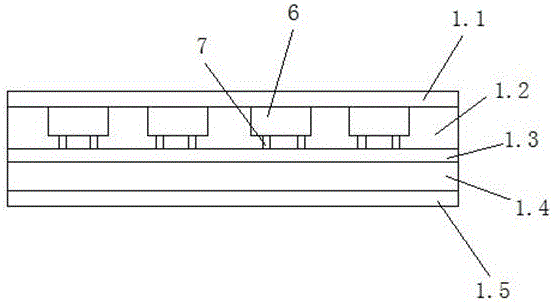

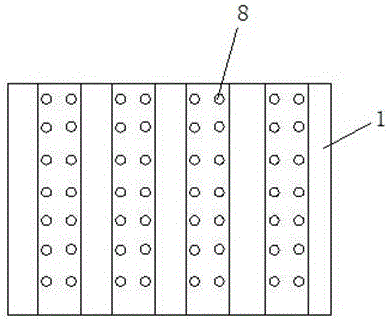

[0024] Such as figure 1 A heat-insulating and sound-insulating polyurethane board shown in and 3, comprising an upper color steel plate 1.1 and a lower color steel plate 1.5, the lower surface of the upper color steel plate 1.1 is connected with a polyurethane core layer 1.2, and the lower surface of the polyurethane core layer 1.2 is provided with a sound-absorbing layer 1.3, there is an insulation material board 1.4 between the sound-absorbing layer 1.3 and the lower color steel plate 1.5, and the insulation material board 1.4 is a cement foam insulation board or a polyurethane insulation board, which has good insulation performance, and the thickness of the insulation material board 1.4 is smaller than that of the polyurethane core Layer 1.2; the surface of the polyurethane core layer 1.2 in contact with the upper color steel plate 1.1 is provided with at least two sound-absorbing grooves 6, the length of the sound-absorbing groove 6 is consistent with the length of the poly...

Embodiment 2

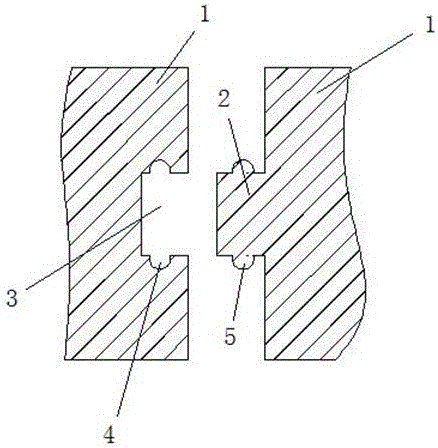

[0026] On the basis of Example 1, we provide the connection mode between the thermal insulation and sound insulation polyurethane boards, such as figure 2 As shown, one end of the polyurethane board 1 is provided with a groove 3, and the other end is provided with a boss 2 matching the groove 3, and the upper and lower inner walls of the groove 3 are respectively provided with a chute 4, and the boss 2 Slide bars 5 matching the chute 4 are respectively formed on the upper and lower sides. When in use, slide the boss 2 of one polyurethane board along the groove 3 of another polyurethane board to connect the two polyurethane boards 1, and slide the chute 4 on the boss 2 into the chute 4 of the groove 3 Inner, making the connection more closely, firm, good heat preservation and sealing.

[0027] The polyurethane board provided in this embodiment has good sound absorption and noise reduction and heat preservation functions. The sound-absorbing groove on the polyurethane board, t...

Embodiment 3

[0029] On the basis of Examples 1 and 2, we also provide the preparation method of the polyurethane core layer in the heat-insulating and sound-insulating polyurethane board, comprising the steps:

[0030] a) Preparation of foaming material: the foaming material is composed of aromatic polyol, polyether polyol, isocyanate, foaming agent, catalyst, stabilizer, aluminum hydroxide, plant powder material and fiber material;

[0031] Aromatic polyols and polyether polyols are configured according to a weight ratio of 4:3, the weight ratio of the total amount of aromatic polyols and polyether polyols to isocyanate is 1 to 3; the weight ratio of the plant powder materials to fiber materials is 2 to 3 ; Relative to 100 parts by weight of the total amount of aromatic polyols and polyether polyols, the total amount of the plant material and the fiber material is 20 to 80 parts by weight, the amount of aluminum hydroxide is 2 to 3.5 parts by weight, hydrogen The particle size of alumina ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com