A kind of recessed anode plane Gunn diode and its manufacturing method

A Gunn diode and anode technology, which is applied in the field of grooved anode plane Gunn diode and its production, can solve the problems of device output power degradation, material quality reduction, and bias voltage reduction, and achieve the effect of increasing operating frequency and output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

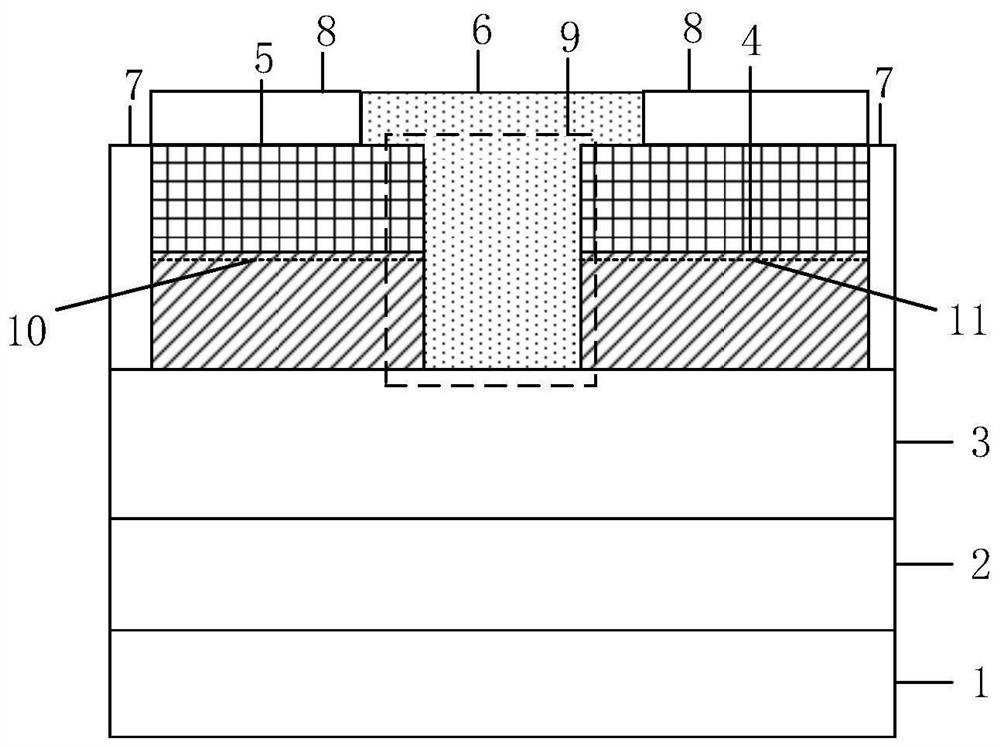

[0046] See figure 1 , figure 1 A structural schematic diagram of a grooved anode double-channel planar Gunn diode provided for an embodiment of the present invention, including: a substrate 1; a nucleation layer 2 located on the substrate 1 and a back barrier layer 3 located on the nucleation layer 2 on the channel layer 4, located on the back barrier layer 3; the barrier layer 5, located on the channel layer 4; wherein, the channel layer 4 and the barrier layer 5 are provided with a groove 9; the anode 6 is located in the concave The groove 9 is located on the back barrier layer 3 and the barrier layer 5; the cathode 7 is located on the back barrier layer 3; the dielectric layer 8 is located on the barrier layer 5.

[0047] In a specific embodiment, the material of the substrate 1 includes but not limited to diamond / sapphire / SiC / high resistance GaN, preferably, the substrate material is diamond.

[0048] In the existing research, the most important factor restricting the re...

Embodiment 2

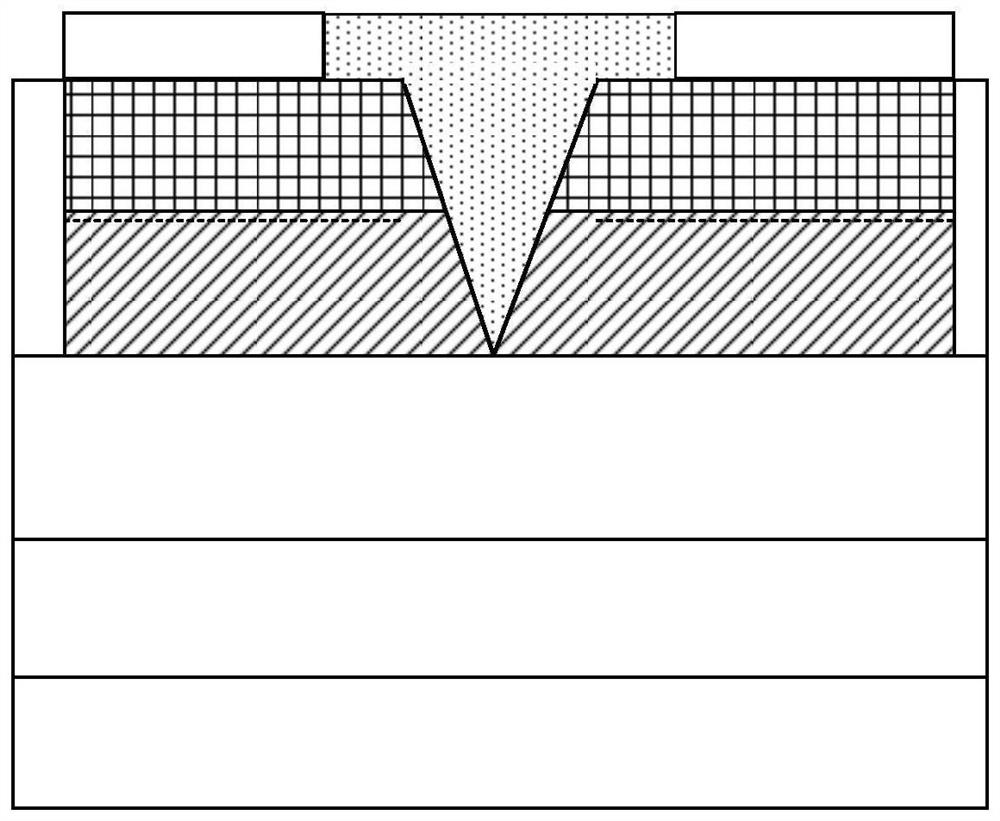

[0068] See Figure 5a-5d , Figure 5a-5d A schematic flow chart of a method for preparing a grooved anode dual-channel planar Gunn diode provided in an embodiment of the present invention, including steps:

[0069] S1. Pretreating the surface of the substrate 1 in the reaction chamber;

[0070] S2, growing nucleation layer 2, back barrier layer 3, channel layer 4 and barrier layer 5 sequentially on the substrate, see Figure 5a ;include:

[0071] S21. Using a chemical vapor deposition process (Chemical Vapor Deposition, CVD for short) or a physical vapor deposition process (Physical Vapor Deposition, PVD), grow an AlN nucleation layer 2 with a thickness of 3 nm to 3 μm on the substrate 1;

[0072] S22. Growing a back barrier layer 3 with a thickness of 100 nm to 1000 nm on the AlN nucleation layer 2 by using a CVD process or a PVD process, and the material of the back barrier layer 3 includes Al x Ga 1-x N, where, Al x Ga 1-x The N material has no intentional doping, an...

Embodiment 3

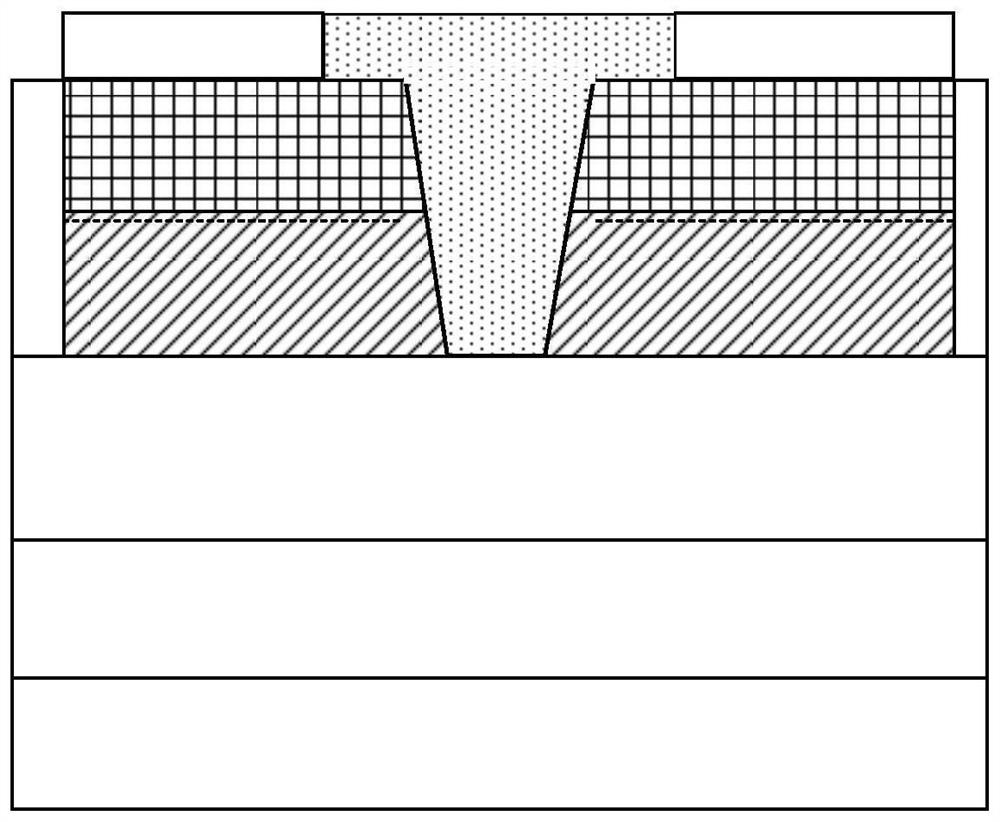

[0090] See Figure 6 , Figure 6 A grooved anode multi-channel planar Gunn diode provided for an embodiment of the present invention includes: a substrate 1; a nucleation layer 2 located on the substrate 1; a back barrier layer 3 located on the nucleation layer 2; The channel layer 64 and the barrier layer 65 are stacked alternately on the back barrier layer 3 in turn; wherein, the channel layer 64 and the barrier layer 65 are provided with a groove 9, and the groove 9 connects the channel layer 64 and the The 2DEG channel formed between the barrier layer 65 is divided into a first 2DEG channel 610 and a second 2DEG channel 611; the anode 6 is located in the groove 9 and on the barrier layer 65; the cathode 7 is located in the back barrier layer 3; the dielectric layer 8 is located on the 2DEG channel structure.

[0091] exist Figure 6 including a channel layer 641 on the back barrier layer 3, a barrier layer 651 on the channel layer 641, a channel layer 642 on the barrier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com