Deep sea parallel multiphase multistage separation reinjection system

A technology of multi-phase separation and parallel connection, which is applied in the direction of production fluid, wellbore/well parts, earthwork drilling and production, etc., can solve problems in deep water field, reduce standpipe static pressure and wellhead back pressure, save energy, reduce small length effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

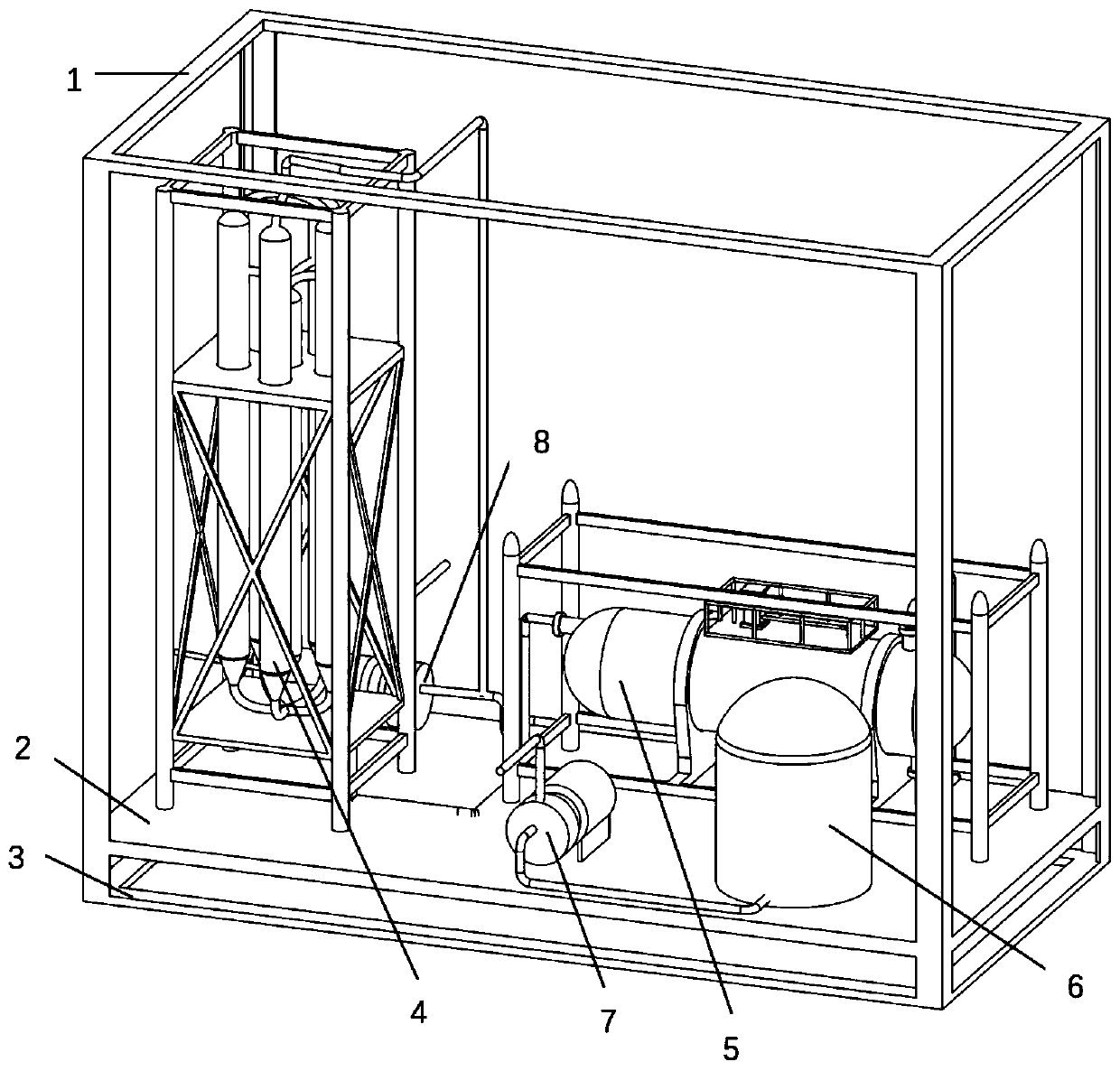

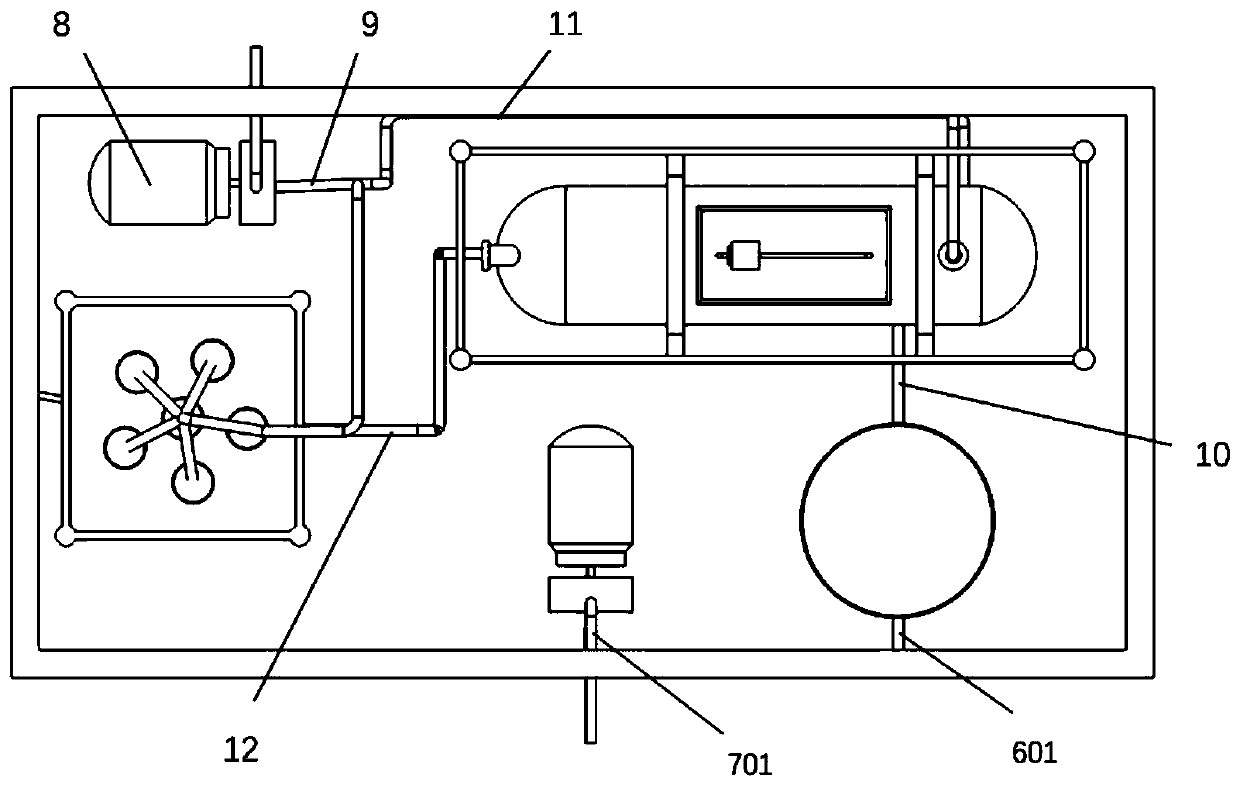

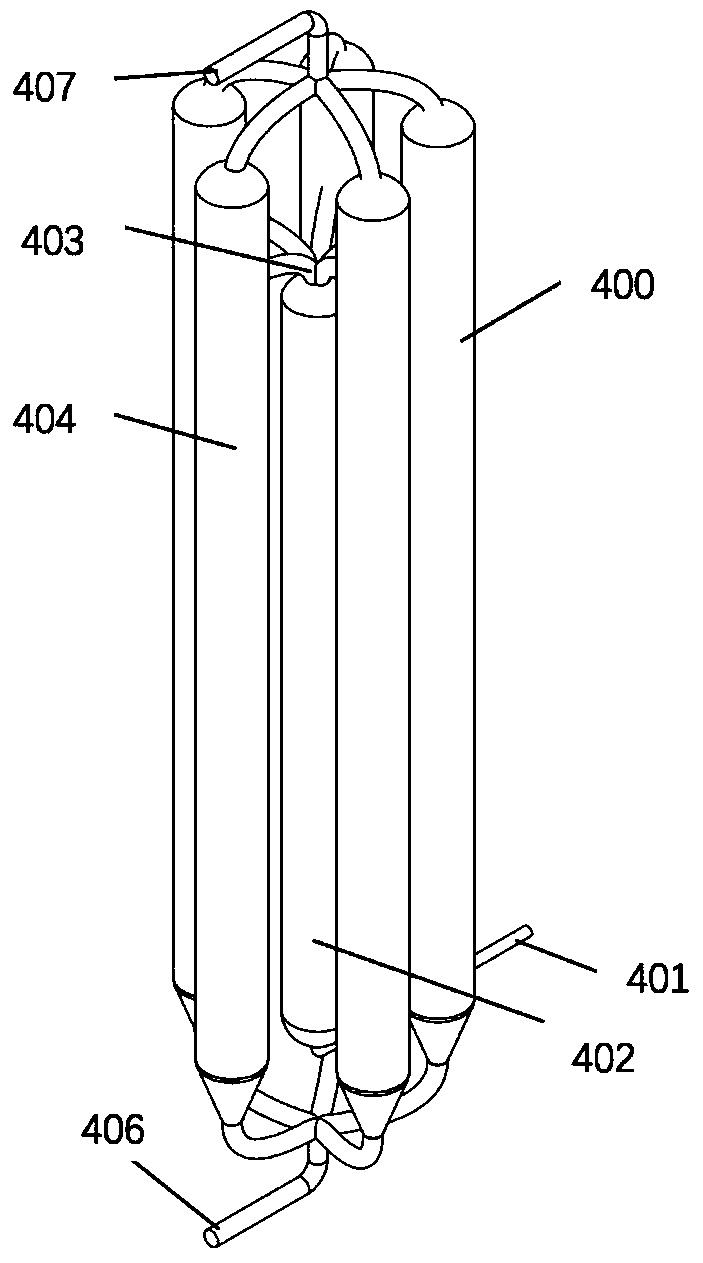

[0026] like figure 1 As shown, the deep-sea parallel multi-stage multi-phase separation and reinjection system includes: base platform 2, vertical parallel separator 4, horizontal gravity separator 5, buffer tank 6, boosted reinjection pump 7 and boosted reinjection pump 8; where: vertical parallel separator 4, horizontal gravity separator 5, buffer tank 6, booster reinjection pump 7 and booster return pump 8 are fixed on the base platform 2; vertical parallel separator 4 is set The mixture inlet 401, the liquid outlet 406 of the vertical gravity separator, the gas outlet 407 of the vertical gravity separator, the delivery pipeline of the subsea oil tree is connected with the mixture inlet 401 of the vertical parallel separator 4, and the produced liquid is discharged from the mixture inlet 401 Send to the deep sea parallel multi-stage multi-phase separation and reinjection system; the horizontal gravity separator 5 is equipped with a horizontal gravity separator inlet 501, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com