Hearth overtemperature protection device

A temperature protection and furnace technology, used in furnace safety devices, furnaces, crucible furnaces, etc., can solve problems such as open circuit, aging of wire insulation, and over-temperature protection devices that cannot continue to work for a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

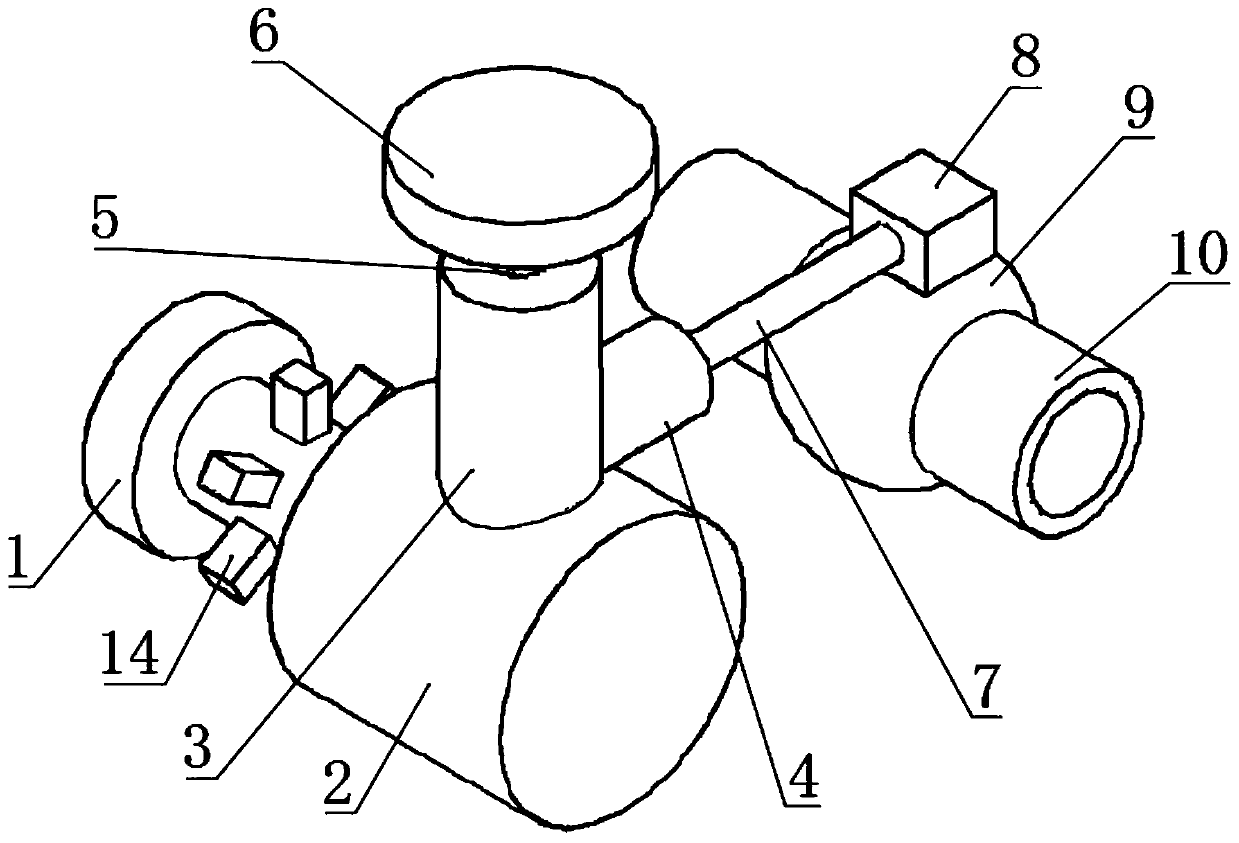

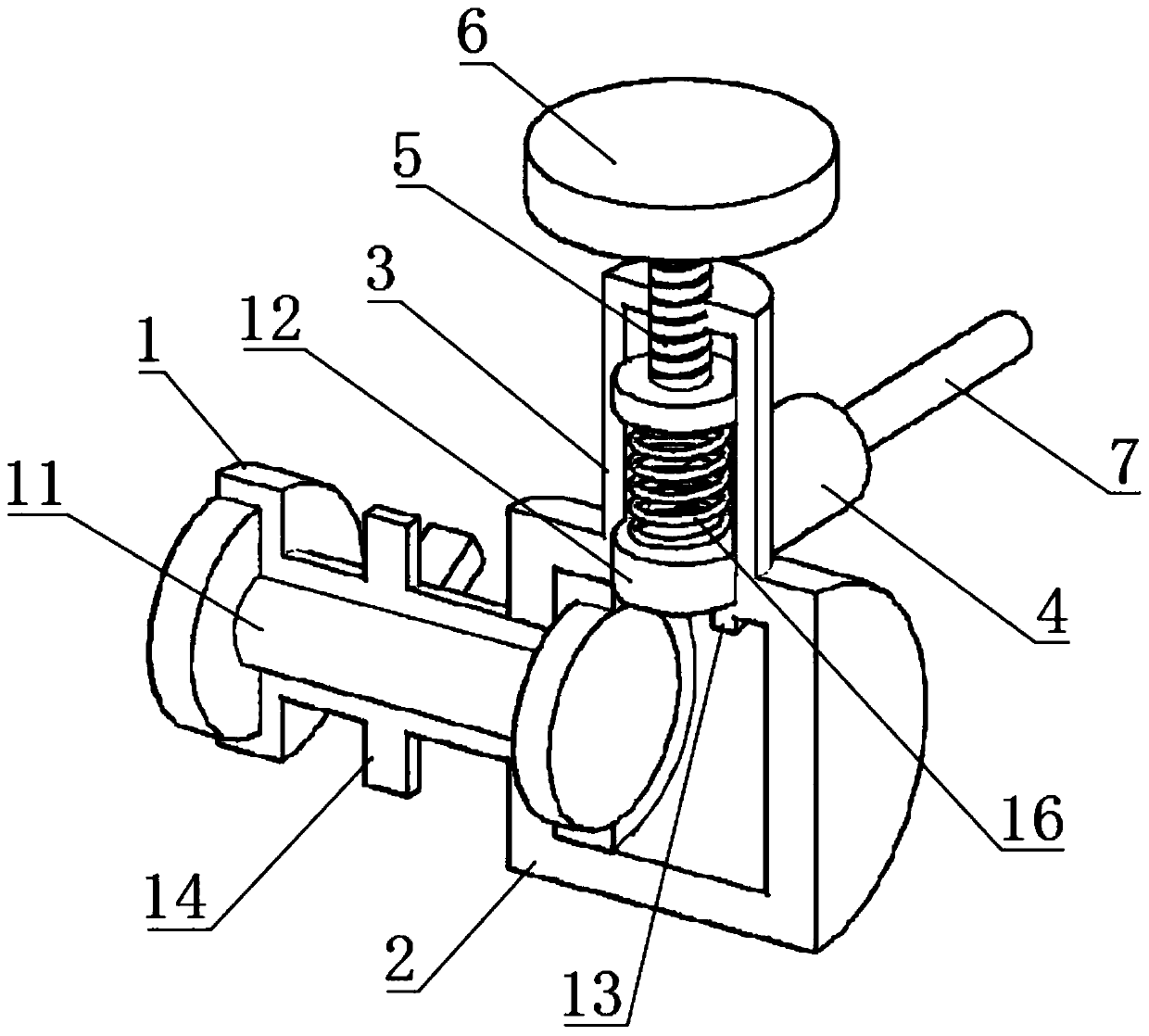

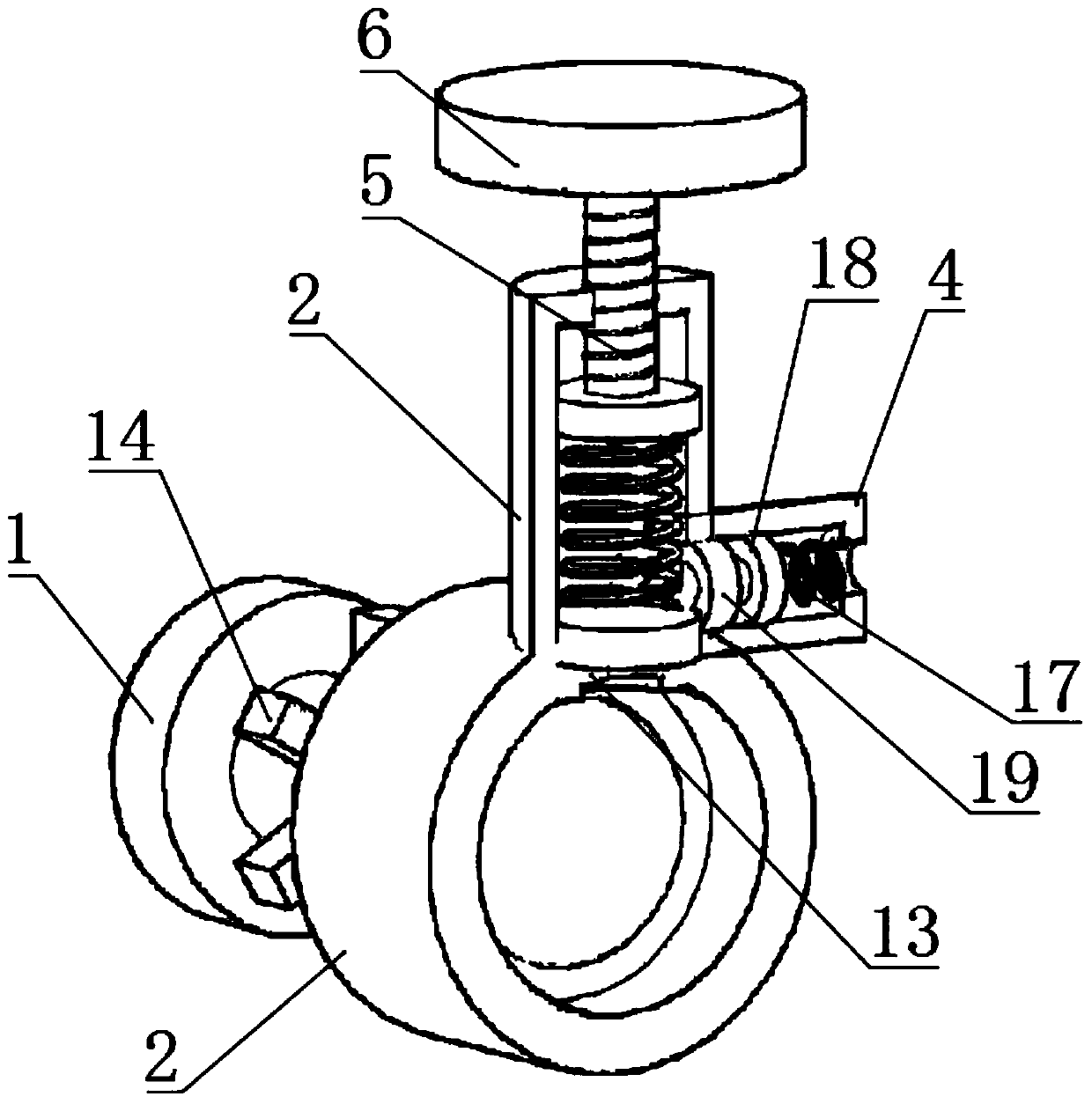

[0021] Such as Figure 1-4 As shown, a furnace overtemperature protection device includes a heat conduction rod 11. The heat conduction rod 11 extends through one end of the seal cylinder 2 to the inside of the seal cylinder 2. The seal cylinder 2 is filled with an expansion medium, and the seal cylinder 2 communicates with the slide cylinder 3. The cylinder 3 is provided with a first piston 12 slidingly connected to the inner wall of the sliding cylinder 3, the side of the sliding cylinder 3 is connected to the connecting cylinder 4, and the connecting cylinder 4 is provided with a sliding rod 15 slidingly connected to it, and one end of the sliding rod 15 is connected to the second piston. 18 is fixedly connected, and the other end of the connecting cylinder 4 is connected to the pressure switch 8 connected to the gas valve 9 through the pressure pipe 7, and the gas valve 9 is connected to the gas pipe 10.

[0022] When the temperature in the furnace rises, the heat pipe ris...

Embodiment 2

[0024] Such as Figure 1-4 As shown, a furnace overtemperature protection device includes a heat conduction rod 11. The heat conduction rod 11 extends through one end of the seal cylinder 2 to the inside of the seal cylinder 2. The seal cylinder 2 is filled with an expansion medium, and the seal cylinder 2 communicates with the slide cylinder 3. The cylinder 3 is provided with a first piston 12 slidingly connected to the inner wall of the sliding cylinder 3, the side of the sliding cylinder 3 is connected to the connecting cylinder 4, and the connecting cylinder 4 is provided with a sliding rod 15 slidingly connected to it, and one end of the sliding rod 15 is connected to the second piston. 18 is fixedly connected, the other end of the connecting cylinder 4 is connected to the pressure switch 8 connected to the gas valve 9 through the pressure pipe 7, the gas valve 9 is connected to the gas pipe 10, and the first piston 12 is far away from the end of the sliding cylinder 3 con...

Embodiment 3

[0027] Such as Figure 1-4 A furnace overtemperature protection device, comprising a heat conduction rod 11, the heat conduction rod 11 extends through one end of the seal cylinder 2 to the inside of the seal cylinder 2, the inside of the seal cylinder 2 is filled with an expansion medium, the seal cylinder 2 communicates with the slide cylinder 3, and the inside of the slide cylinder 3 There is a first piston 12 slidingly connected to the inner wall of the sliding cylinder 3, the side of the sliding cylinder 3 is connected to the connecting cylinder 4, and the connecting cylinder 4 is provided with a sliding rod 15 slidingly connected to it, and one end of the sliding rod 15 is fixedly connected to the second piston 18 The other end of the connecting cylinder 4 is connected to the pressure switch 8 connected to the gas valve 9 through the pressure pipe 7, the gas valve 9 is connected to the gas pipe 10, the other end of the compression spring 16 is fixedly connected to the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com