Preparation method for simultaneously obtaining tea hydrolat and primary tea

A technology for tea and pure dew, which is applied in the field of preparation of tea pure dew and first tea at the same time, can solve the problems of oxidation and degradation of tea aroma substances, tea can no longer be used, and the actual tea aroma does not match, so as to achieve a light and refreshing taste. Sweet, avoid pollution problems, the effect of the soup color is yellow-green and clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

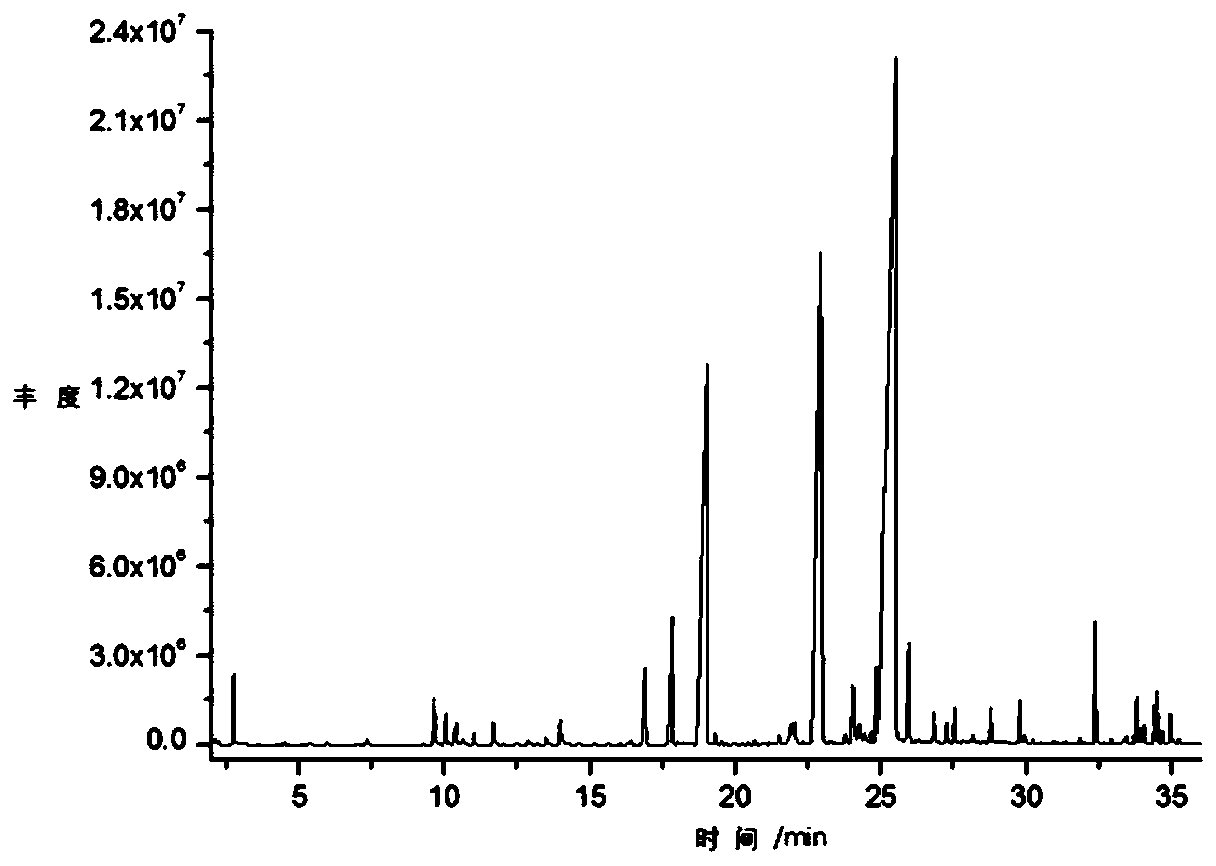

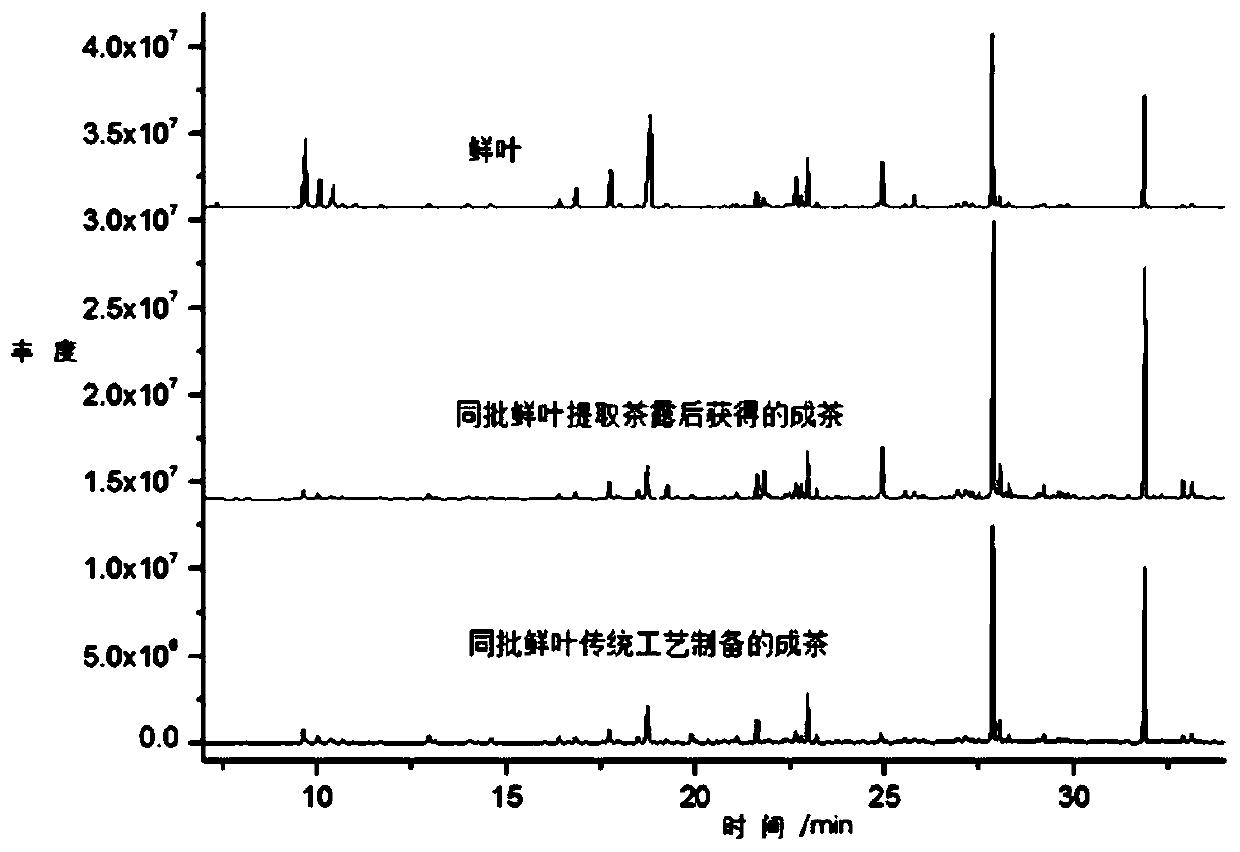

[0038] A preparation method for simultaneously obtaining tea hydrosol and green tea, comprising the following steps:

[0039] (1) Use the fresh tea leaves of green tea as raw materials, stir under anhydrous conditions, distill the fresh tea leaves under reduced pressure at 70°C and -0.8MPa for 3 hours, collect the distillate, and obtain transparent and colorless tea leaves pure dew;

[0040] (2) When the above process is carried out until no tea dew drips out, green tea is obtained.

Embodiment 1B

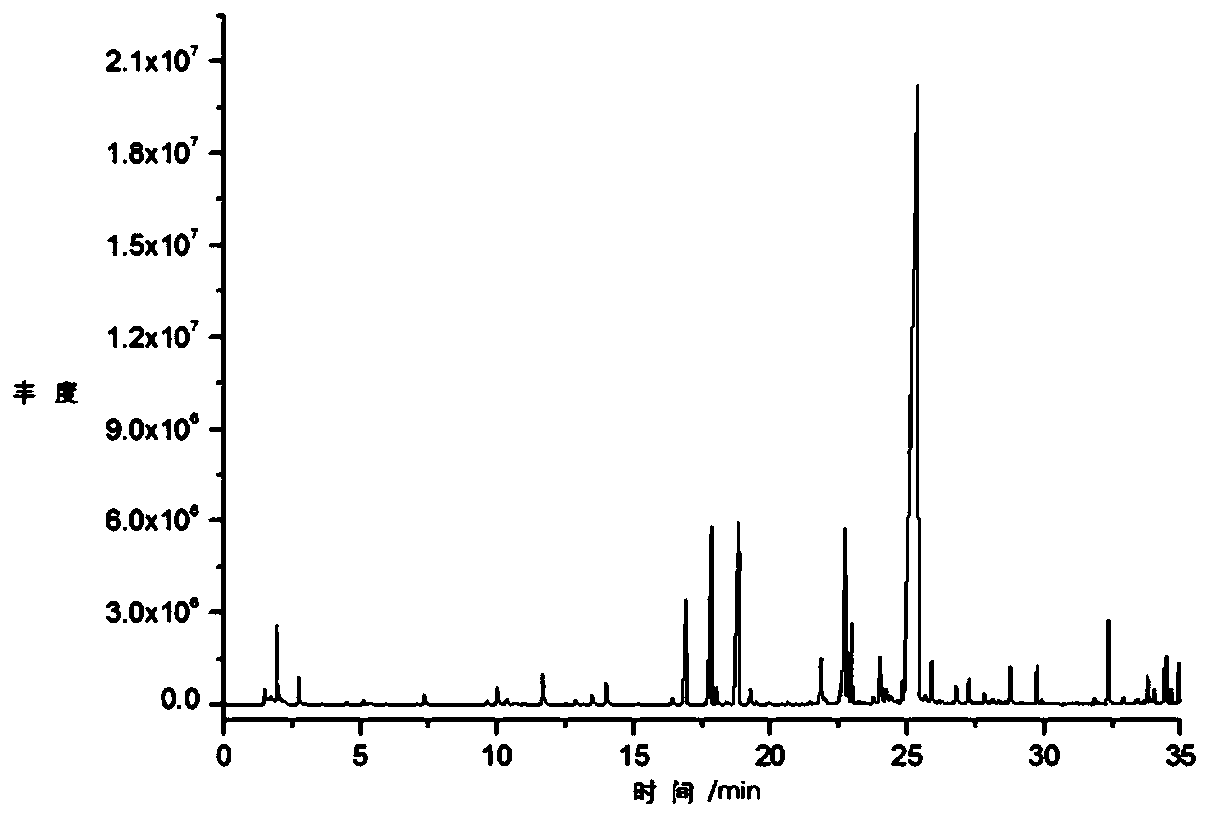

[0042] A preparation method for simultaneously obtaining tea pure dew and white tea, comprising the following steps:

[0043] (1) Take the fresh tea leaves of white tea as raw materials, stir them under anhydrous conditions, distill the fresh tea leaves under reduced pressure at -1 MPa at 40°C for 5 hours, collect the distillate, and obtain transparent and colorless tea leaves. dew;

[0044] (2) When the above process is carried out until no tea dew drips out, the first tea of white tea is obtained.

Embodiment 1C

[0046] A preparation method for simultaneously obtaining tea hydrosol and green tea, comprising the following steps:

[0047] (1) Use the fresh tea leaves of green tea as raw materials, stir under anhydrous conditions, distill the fresh tea leaves under reduced pressure at 95°C and a vacuum of -0.6MPa for 2 hours, collect the distillate, and obtain transparent and colorless Tea Hydrosol;

[0048] (2) When the above process is carried out until no tea dew drips out, green tea is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com