Gas electromagnetic heating device and control method

A technology of electromagnetic heating device and control method, which is applied in heating methods, air heaters, fluid heaters, etc., and can solve problems such as inaccurate temperature control, low thermal efficiency, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

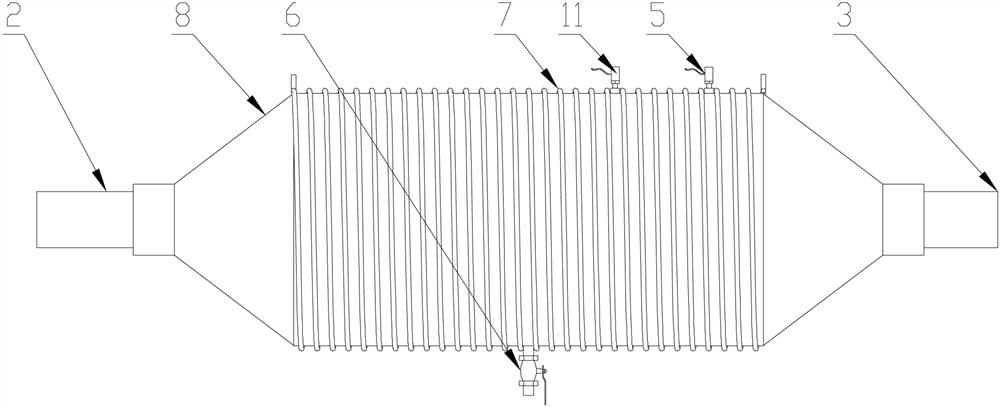

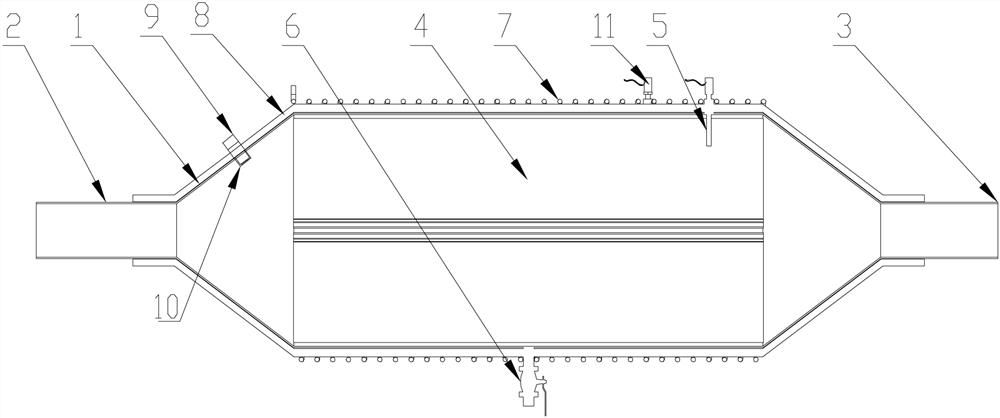

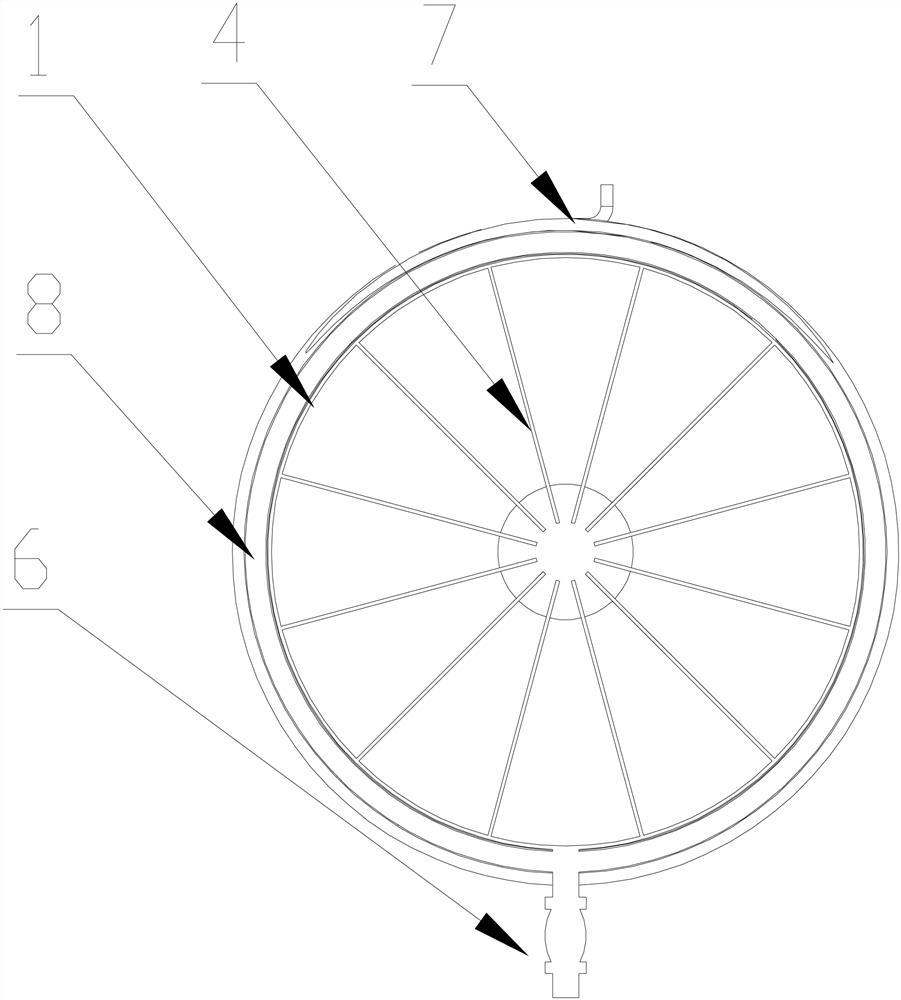

[0031] see Figure 1-5 , a gas electromagnetic heating device, which includes a cylinder 1, one end of the cylinder 1 is provided with an air inlet 2, the other end of the cylinder 1 is provided with an air outlet 3, and the inside of the cylinder 1 is provided with uniformly distributed It is a heat sink 4 that emits radiation. The outside of the cylinder 1 is wrapped with a heat-insulating insulating layer 8, and the outside of the heat-insulating insulating layer 8 is wound with a high-temperature-resistant wire 7. The high-temperature-resistant wire 7 and electromagnetic induction heating The power supply 13 is connected. The heating device can be used not only for heating dry air, for providing dry hot air, but also for heating steam with high humidity, for generating high-temperature steam, and for steam greening during tea processing. In the specific working process, the above-mentioned electromagnetic induction heating power supply 13 can provide current to the high t...

Embodiment 2

[0039] A blower is used to pass air into the cylinder body 1 through the air inlet 2, and the electromagnetic induction heating power supply 13 is started in advance to provide current to the high-temperature resistant wire 7, and electromagnetic heating is realized for the heat sink 4 inside it, and then the air is heated. in process

[0040] Monitor the temperature of the air outlet inside the barrel 1 in real time through the temperature probe 5, and transmit the signal to the controller, and compare it with the required temperature value through the controller. When the temperature reaches the set value, the controller 14 controls the electromagnetic induction heating power supply 13 is turned off, and then stops heating; when the temperature is lower than the set value, the controller 14 controls the electromagnetic induction heating power supply 13 to turn on, and then continues to heat up;

[0041] The humidity of the air inside the cylinder 1 is monitored by the humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com