How to make electrodes

A production method and electrode sheet technology, which are applied in the direction of electrode manufacturing, battery electrodes, electrode melt treatment, etc., can solve the problems of aggravating active materials, damage to the irregularity of the shape of the tab position, and large heating area, and achieve the preparation process Convenience, improvement of poor powder coating, clear heating area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

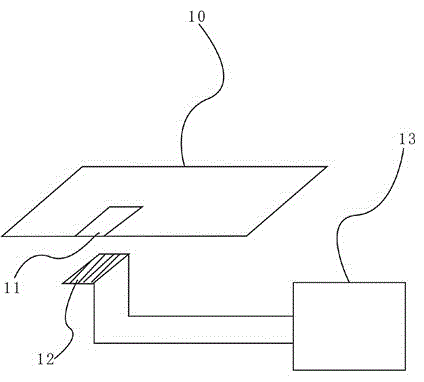

[0030] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

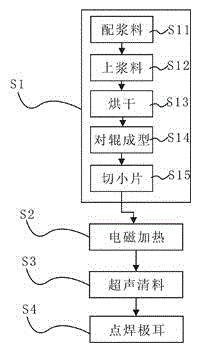

[0031] see Figure 1-2 , the preparation method of electrode sheet of the present invention, comprises the following steps:

[0032] Step S1, preparation of semi-finished electrode sheet 10: select a metal current collector that can be magnetized, and use a wet process to obtain a semi-finished electrode sheet 10; this step specifically includes the following steps: Step S11, preparation of slurry: active material, additive, Mix the binder and water evenly to obtain a slurry; step S12, sizing: pour the slurry into the paddle funnel, and fill the slurry into the current collector through the paddle funnel, and form the first molded product; step S13 , drying: pulling the first molded product into an oven to be heated to dry, and forming a second molded product; step S14, pair-roll molding: rolling the second molde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com