Laver smasher

A pulverizer and seaweed technology, applied in grain processing and other directions, can solve the problems of low production continuity and uneven pulverization, and achieve the effects of simple structure, high continuity and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

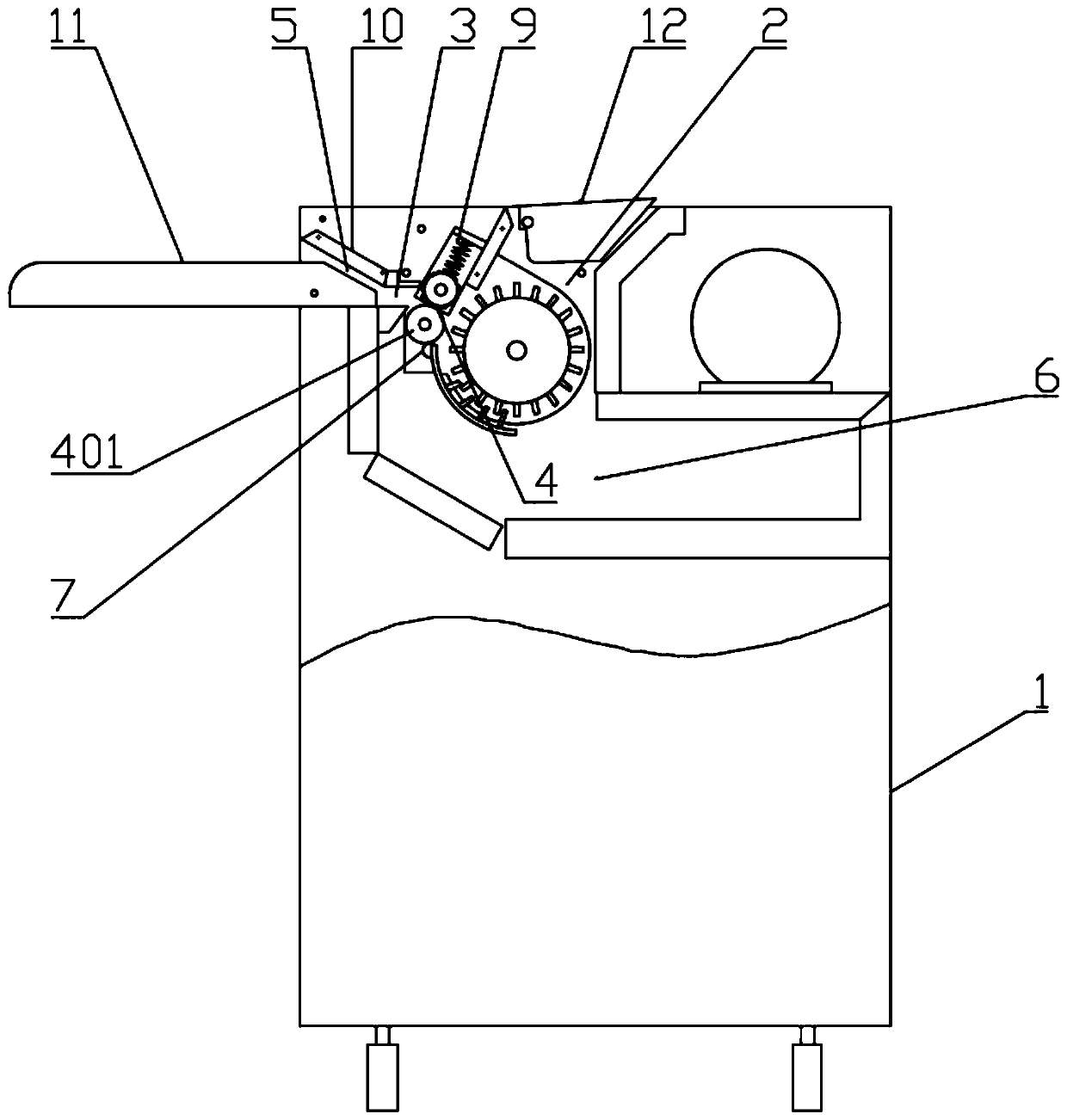

[0024] refer to figure 1 , a kind of laver pulverizer, comprises cabinet 1, is provided with pulverizing chamber 2 in cabinet 1, is provided with feeding port 3 on the side top of pulverizing chamber 2, and feeding port 3 is provided with feeding device 4, and feeding port 3 A feed channel 5 is connected, and a discharge channel 6 is connected below the crushing chamber 2;

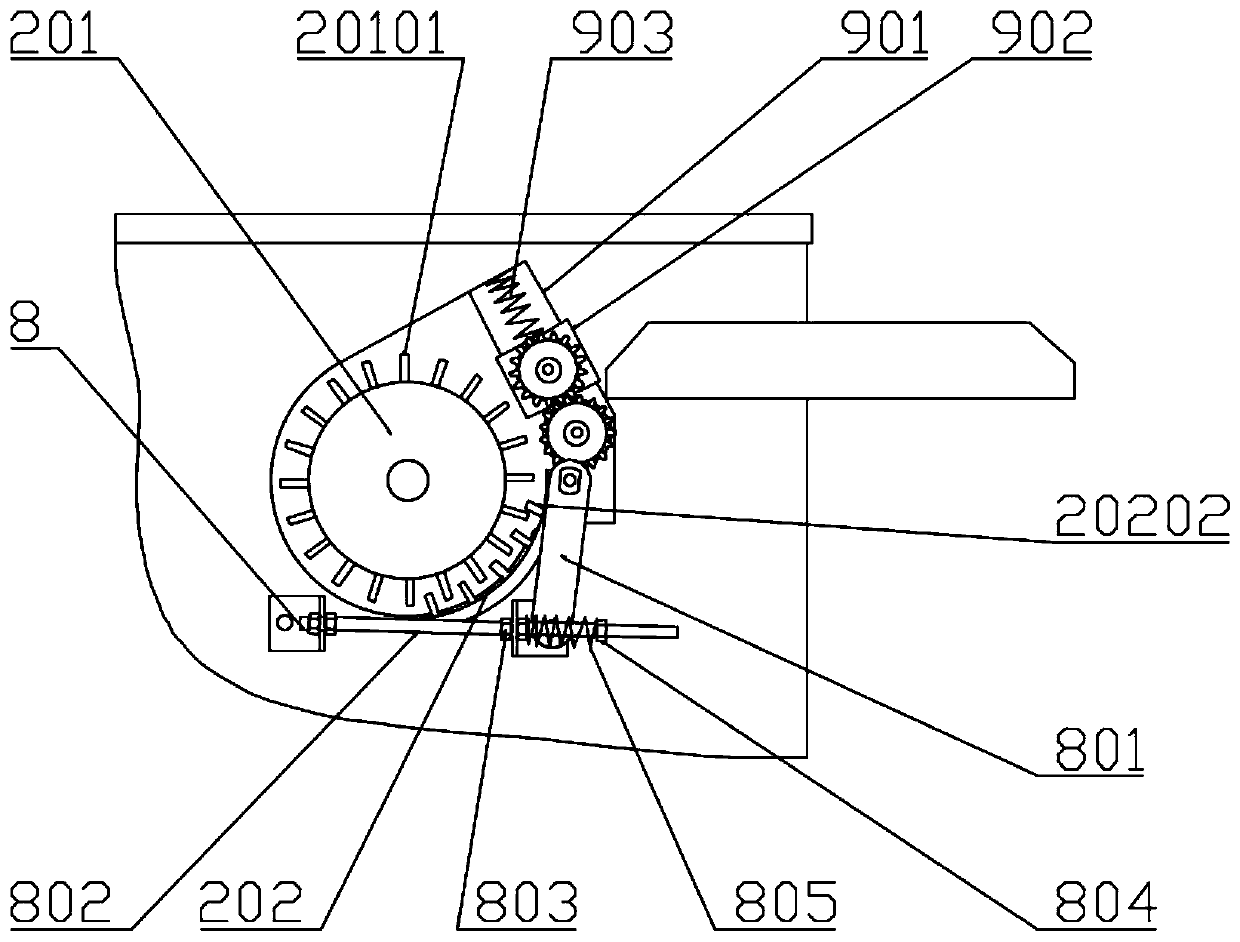

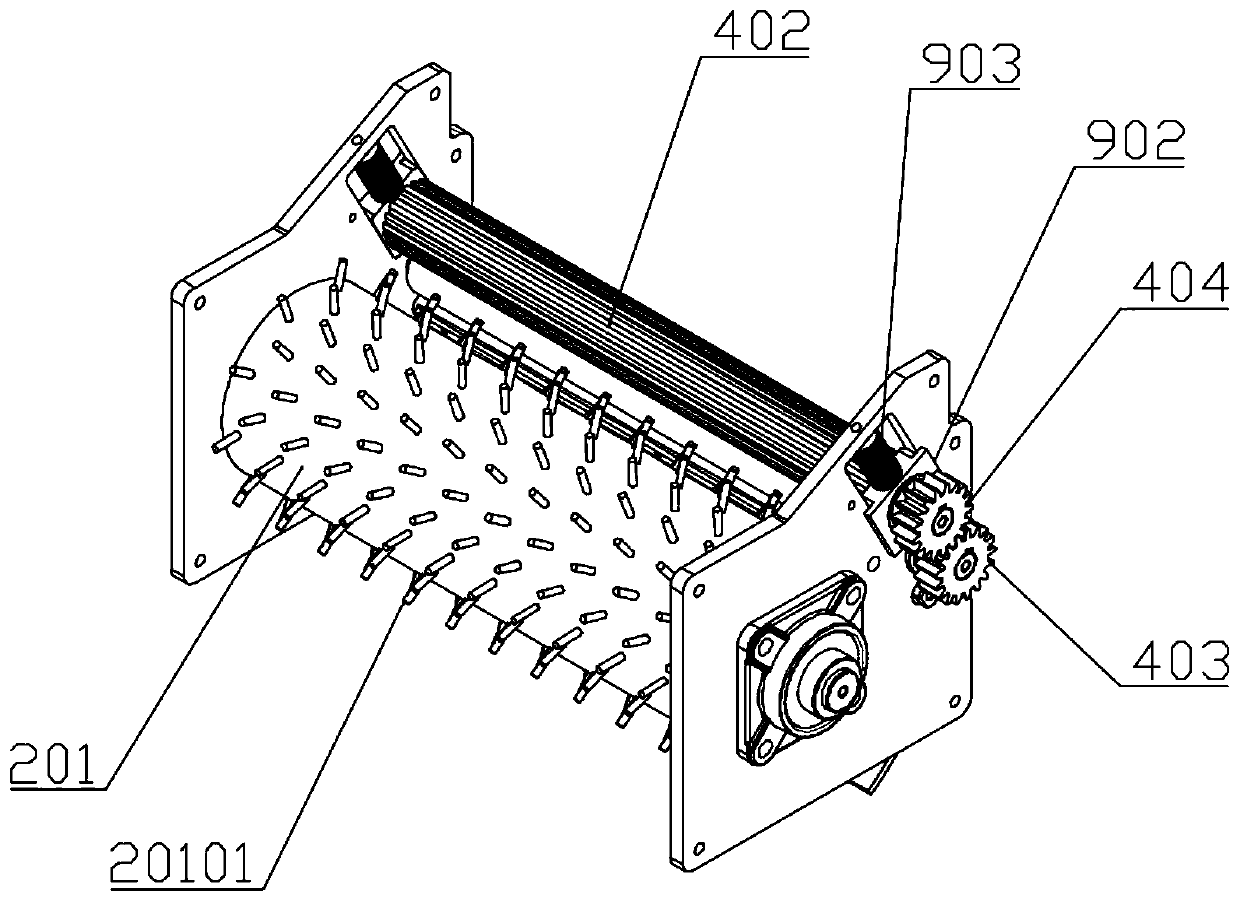

[0025] A crushing roller 201 is arranged in the crushing chamber 2, and outer crushing teeth 20101 are radially and evenly distributed on the outer peripheral surface of the crushing roller 201. The arc-shaped jaw plate 202 is arranged below, and the top of the arc-shaped jaw plate 202 is rotated and installed on the box walls on both sides of the cabinet 1 through the swing shaft 7. , the inner crushing teeth 20202 interlaced with the outer crushing teeth 20101 of the crushing roller 201 are evenly distributed on the arc-shaped concave surface of the arc-shaped jaw plate 202. A swing adjustment mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com