High-pressure rubber pipe producing and manufacturing method

A technology of high-pressure rubber hose and manufacturing method, which is applied to tubular objects, other household appliances, household appliances, etc., and can solve the problems of high-pressure rubber hoses such as poor strength, loose arrangement, and many winding layers, so as to ensure service life, good winding effect, evenly arranged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

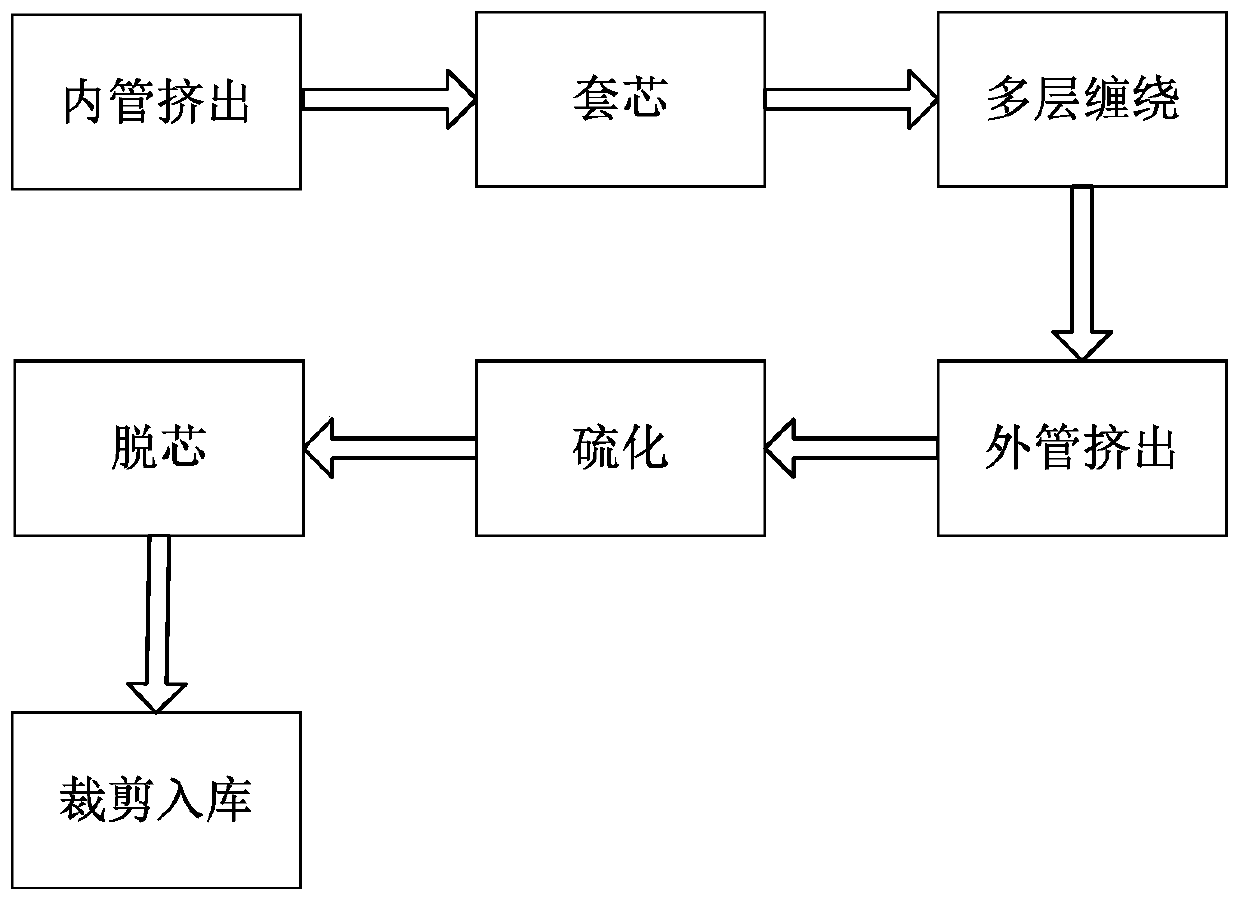

[0038] Such as Figure 1 to Figure 6 Shown, a kind of high-pressure rubber hose manufacturing method comprises the following steps:

[0039] S1. Inner tube extrusion: Extrude the inner rubber tube through the extruder;

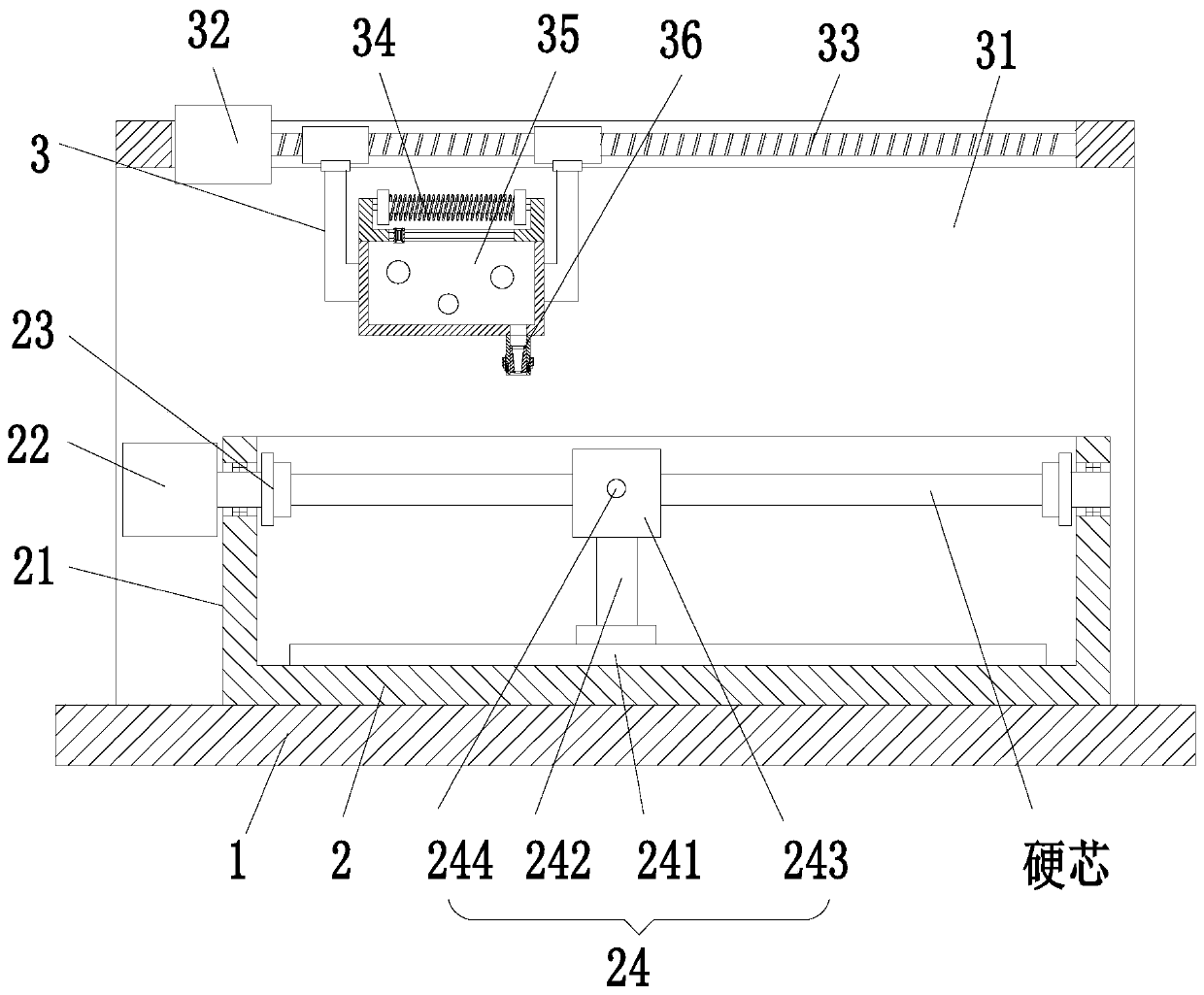

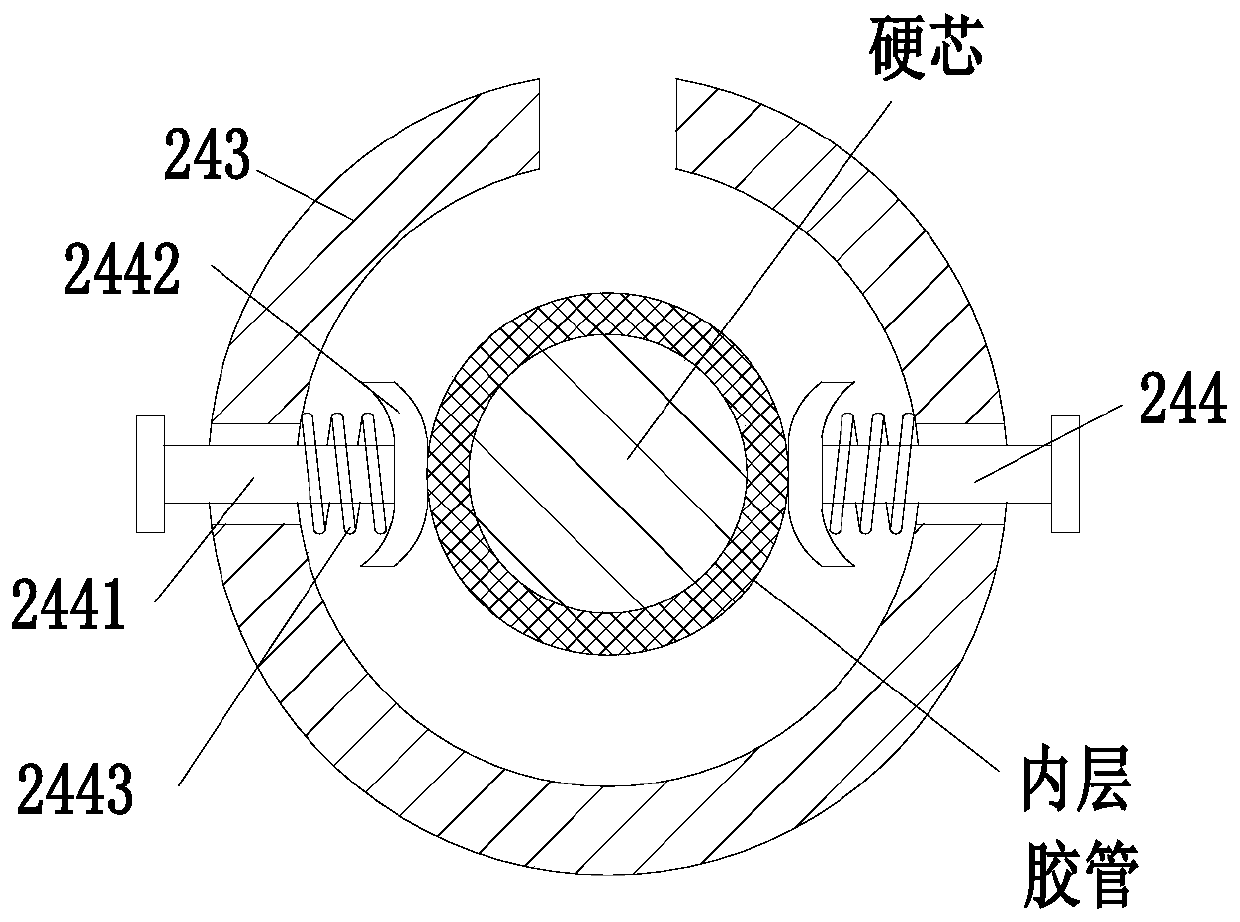

[0040] S2. Sleeve core: First, evenly coat the mold release agent on the hard core, then put the inner rubber tube extruded in step S1 on the hard core, and install the hard core on the placement device 2;

[0041] S3, multi-layer winding: use the winding device 3 to spirally wind the steel wire rope on the outside of the inner rubber hose in step S2 according to the winding angle, and the number of winding layers is an even number, and the direction of rotation of adjacent winding layers is opposite;

[0042] S4. Extrusion of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap