Rotary table bearing with high limit speed

A technology for limiting rotational speed and turntable bearings, applied in the field of bearings, it can solve the problems of temperature rise in the bearing raceway, burns of parts such as raceways and rollers, spin motion of cylindrical rollers, etc., and achieve edge contact stress reduction and service life. The effect of prolongation and speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

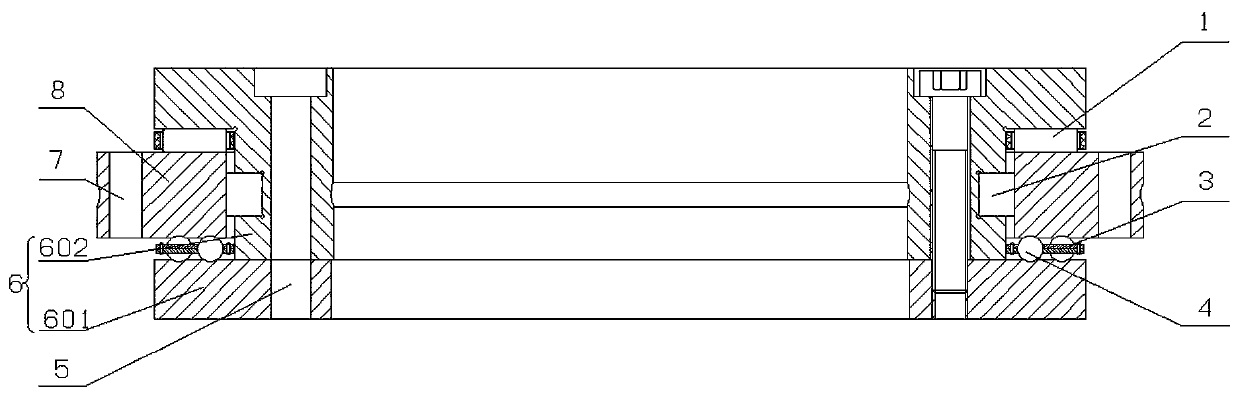

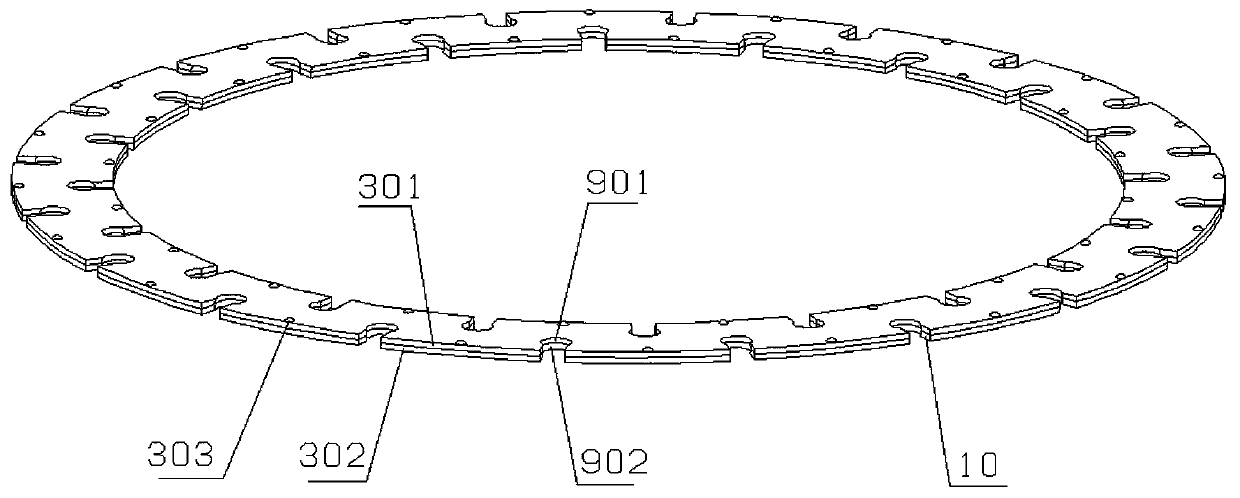

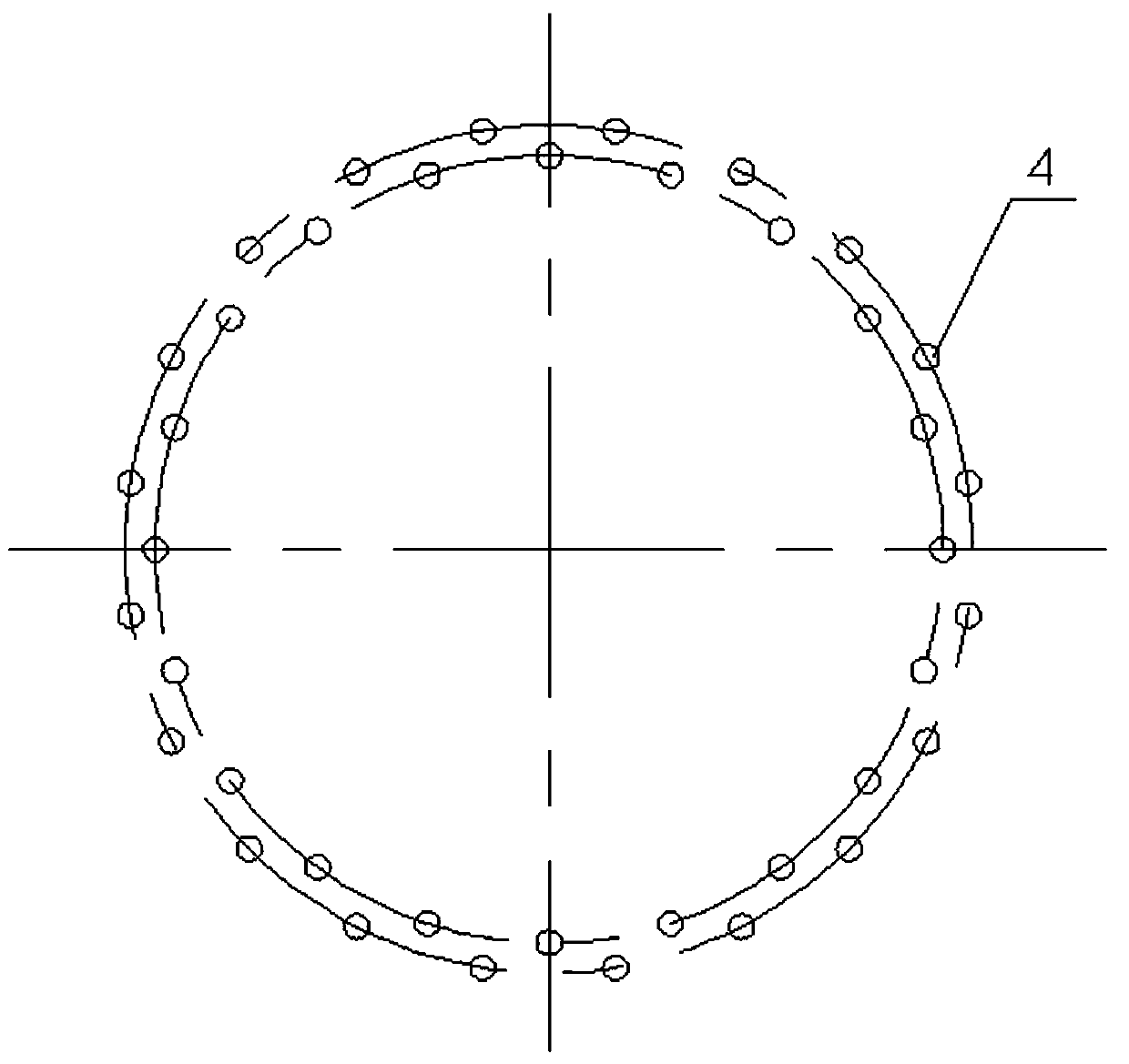

[0026] Such as figure 1 As shown, a turntable bearing with a high limit speed of the present invention is similar in main structure to a conventional turntable bearing, both including an inner ring 6 and an outer ring 8 rotatably arranged on the outer periphery of the inner ring 6 . The outer ring 8 is ring-shaped, and the inner ring 6 is I-shaped. The upper edge of the outer ring 8 and the lower edge of the upper end of the inner ring 6 are matched by a plurality of first rolling elements 1. The inner edge of the outer ring 8 and the middle part of the inner ring 6 The outer edge of the outer ring is matched by a plurality of second rolling elements 2, and the lower edge of the outer ring 8 is matched with the upper edge of the lower end of the inner ring 6 by a plurality of third rolling elements 4. For ease of assembly, the inner ring 6 is split and includes an upper ring 602 and a lower ring 601 . The outer ring 8 is provided with a first installation hole 7 for fixing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com