Ultra-high-temperature oil temperature machine with cooling control function

A technology of cooling control and ultra-high temperature, applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of lack of cooling function and low temperature, and achieve controllable test temperature and good temperature stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

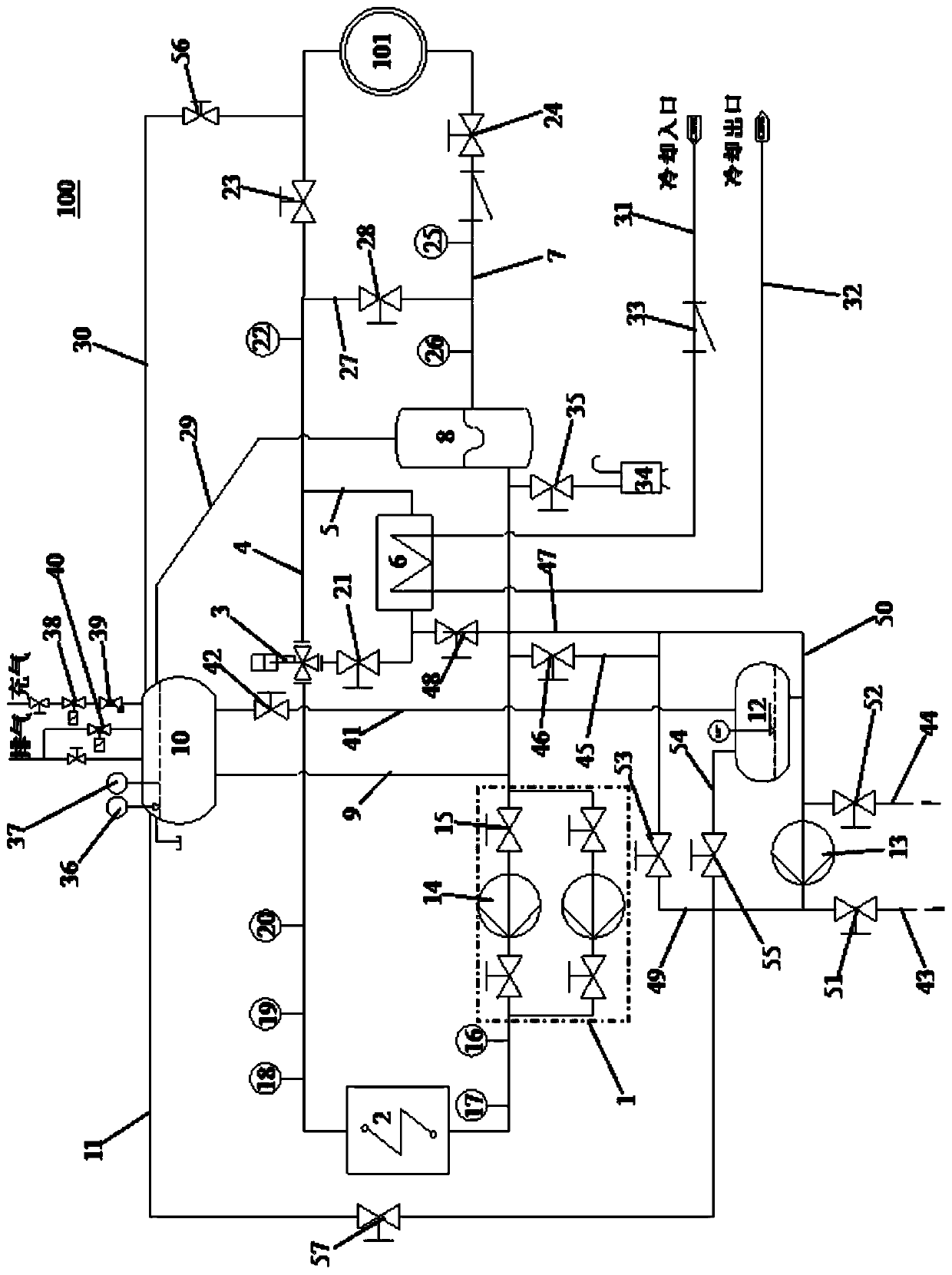

[0022] Please refer to figure 1 , the present embodiment is an ultra-high temperature oil temperature machine 100 with cooling control, which includes a circulation pumping device 1 connected to a circulation loop through pipelines, an organic heat carrier furnace 2, a client 101, and the output of the organic heat carrier furnace 2 A proportional three-way valve 3 is installed on the side to connect the first pipeline 4 and the second pipeline 5 to the client 101. The second pipeline 5 is provided with a heat exchanger 6, and the heat transfer oil in the second pipeline 5 passes through the heat exchanger. The heat exchanger 6 exchanges heat with a cooling circulation unit (not marked in the figure), and the heat transfer oil in the client 101 returns to the circulating pumping device 1 through the oil return pipe 7, and the oil return pipe 7 is provided with an air collecting tank 8. The input end of the circulating pumping device 1 is connected to a high-level expansion tan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap