High temperature resistant and anti-corrosion coating structure for heat exchanger

A high-temperature-resistant and anti-corrosion technology, which is applied in the field of high-temperature-resistant and anti-corrosion coating structures for heat exchangers, can solve the problems of affecting the protective effect of silicaldehyde anti-corrosion coating heat exchange tubes, high temperature and pressure requirements, and long complete curing time. , to achieve the effect of improving high temperature resistance and corrosion resistance, good bonding force and excellent creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

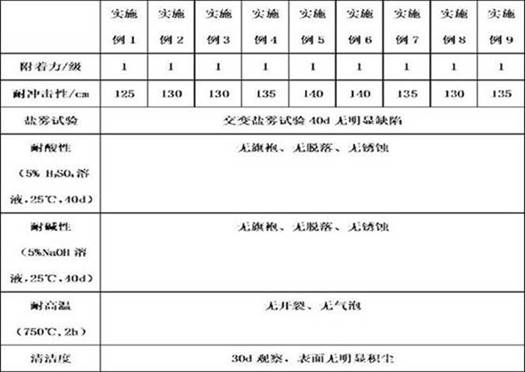

Examples

Embodiment 1

[0032] The invention discloses a high-temperature-resistant anti-corrosion coating structure for a heat exchanger, which is coated on the inner wall of a heat exchange plate and the surface of a heat exchange tube or a heat exchange plate. The high-temperature-resistant anti-corrosion coating structure is a composite coating structure. The composite coating structure includes a polyurea filling layer coated on the inner wall of the heat exchange plate and the surface of the heat exchange tube or heat exchange plate, the polyurea filling layer is coated with a modified PPSU wear-resistant layer, and the modified PPSU is wear-resistant The layer is coated with a super-hydrophobic nano-silica coating, the super-hydrophobic nano-silica coating is a gradient composite layer structure, and the particle size of the different composite layers of the super-hydrophobic nano-silica coating is gradient from the inside to the outside. increment.

[0033] In this embodiment, the polyurea fi...

Embodiment 2

[0035] The invention discloses a high-temperature-resistant anti-corrosion coating structure for a heat exchanger, which is coated on the inner wall of a heat exchange plate and the surface of a heat exchange tube or a heat exchange plate. The high-temperature-resistant anti-corrosion coating structure is a composite coating structure. The composite coating structure includes a polyurea filling layer coated on the inner wall of the heat exchange plate and the surface of the heat exchange tube or heat exchange plate, the polyurea filling layer is coated with a modified PPSU wear-resistant layer, and the modified PPSU is wear-resistant The layer is coated with a super-hydrophobic nano-silica coating, the super-hydrophobic nano-silica coating is a gradient composite layer structure, and the particle size of the different composite layers of the super-hydrophobic nano-silica coating is gradient from the inside to the outside. increment.

[0036] In this embodiment, the polyurea fi...

Embodiment 3

[0038] The invention discloses a high-temperature-resistant anti-corrosion coating structure for a heat exchanger, which is coated on the inner wall of a heat exchange plate and the surface of a heat exchange tube or a heat exchange plate. The high-temperature-resistant anti-corrosion coating structure is a composite coating structure. The composite coating structure includes a polyurea filling layer coated on the inner wall of the heat exchange plate and the surface of the heat exchange tube or heat exchange plate, the polyurea filling layer is coated with a modified PPSU wear-resistant layer, and the modified PPSU is wear-resistant The layer is coated with a super-hydrophobic nano-silica coating, the super-hydrophobic nano-silica coating is a gradient composite layer structure, and the particle size of the different composite layers of the super-hydrophobic nano-silica coating is gradient from the inside to the outside. increment.

[0039]In this embodiment, the polyurea fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com